-

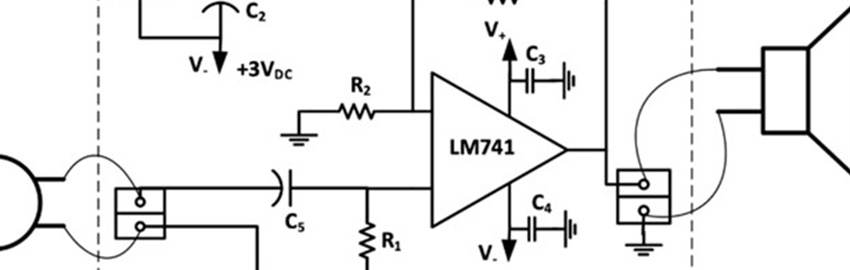

Optimizing Mixed Signal Circuit Designs

Navigating the analog and digital worlds. READ MORE...

-

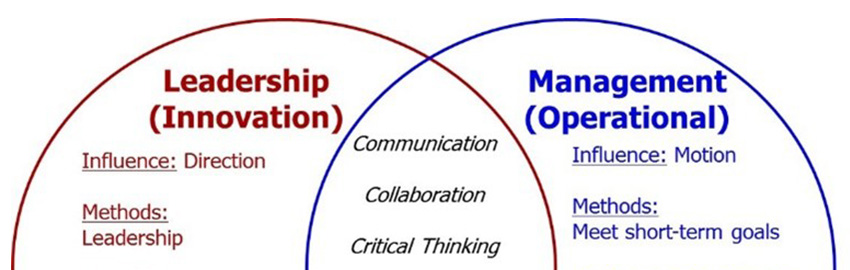

Developing Organizational Culture for Troubleshooting

Solving problems and adding value. READ MORE...

-

Cloud Collaboration

Real-time breakdowns cost more than you think. READ MORE...

-

The Experts' Take on AI

What’s working now and what’s not (but should be).

READ MORE... -

Designing for High-Pin Count Devices

Overcoming “anywhere but here.” READ MORE...

-

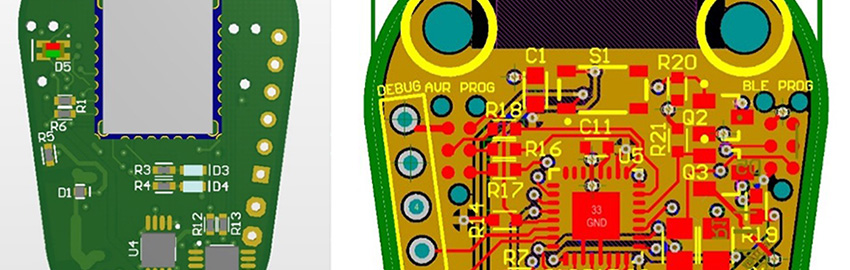

Bluetooth Design

6 steps for limiting interference and data loss. READ MORE...

Homepage Slideshow

Optimizing Mixed Signal Circuit Designs

Navigating the analog and digital worlds.

Developing Organizational Culture for Troubleshooting

Solving problems and adding value.

Cloud Collaboration

Real-time breakdowns cost more than you think.

The Experts' Take on AI

What’s working now and what’s not (but should be).

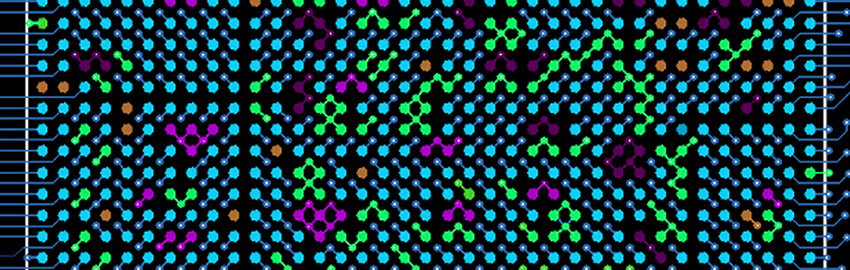

Designing for High-Pin Count Devices

Overcoming “anywhere but here.”

Bluetooth Design

6 steps for limiting interference and data loss.