NESS ZIONA, ISRAEL – Nearly 91% of respondents to a recent Nano Dimension survey expect 3D printed electronics will be a strategic direction. More than three quarters (76%) are already exploring the technology for design validation (31%), prototyping (40%) and low-volume custom manufacturing (29%), according to the electrifying additive manufacturing survey.

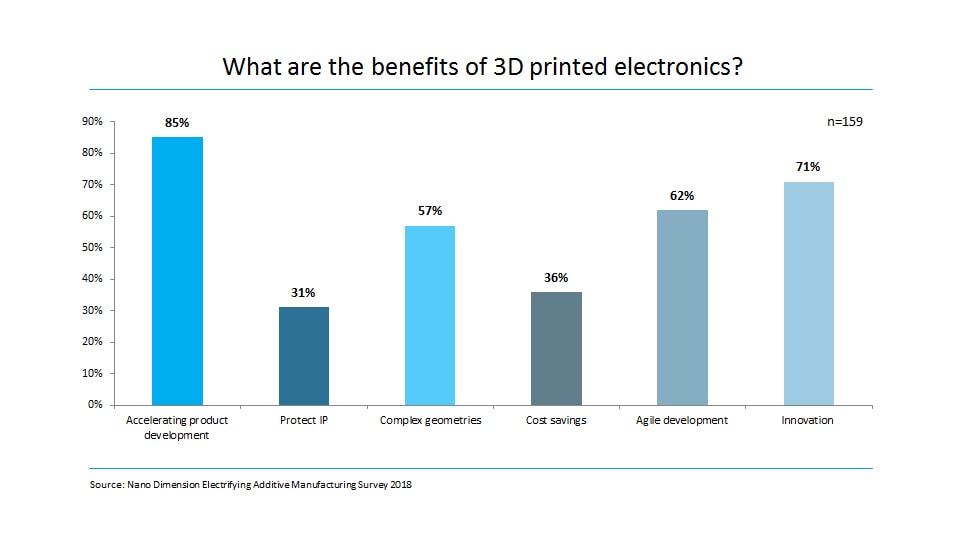

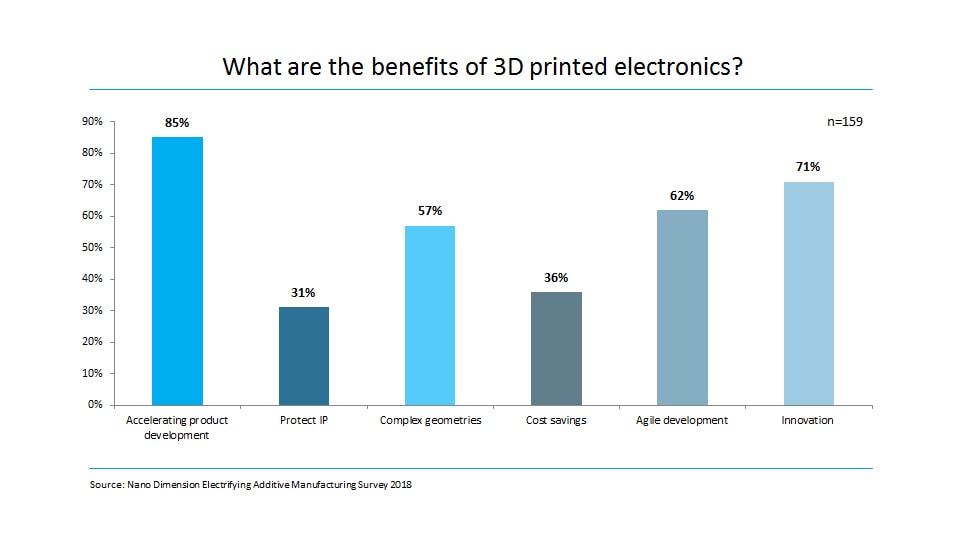

The firm surveyed 159 respondents globally, including engineers, designers and business decision makers across multiple industry sectors. The findings show 3D printed electronics technology is important for agility and the ability to accelerate product development, realize greater design innovation and build more complex geometries – all of which will help them stay ahead of competitors, says Nano Dimension.

More than 75% saying they rely on short-run, low-volume external PCB prototyping services, and 73% saying they go through at least two, and often more than three, iterations before reaching the final prototyping and testing phase.

Levels of confidence about being vulnerable to IP theft were high. Almost 70% of respondents said they worry about their intellectual property when they send their designs to third-party prototyping facilities.

Companies also face concerns over issues such as prototyping lead times. Survey respondents noted the lead times for receiving prototypes when they use outside prototyping facilities range from 1 to 2 weeks (37%), while 33% cited times of 2 to 4 weeks, and 11% said it can take longer than 4 weeks. Some 19% said it took less than a week.

Register now for PCB WEST, the leading trade show for the printed circuit design and electronics manufacturing industry! Coming Sept. 11-13 to the Santa Clara Convention Center.