WILSONVILLE, OR -- Mentor today announced the new Xpedition printed circuit board (PCB) design platform focused on multi-dimensional verification.

The added embedded features cover automated schematic verification and testability and leverage technology developed by Mentor subsidiaries Validate and Valor.

The additional functionality in Xpedition represents Mentor's latest attempt to contend with the increasing complexities of today’s systems. A lack of robust verification tools -- or the difficulty applying these tools -- leads to scores of respins and extends time-to-market.

According to a recent electronics simulation-driven design study by Lifecycle Insights, the average number of design respins is 2.9 per project, which amounts to approximately 16 days of unplanned development time and more than $82,000 in additional costs. The study found that PCB design teams that performed upfront verification across their design processes realized a 14% increase in on-time project delivery, reduced respins, and overall improved design quality.

In response, Mentor has integrated a range of easy-to-use verification tools into its premier PCB design platform. The singular authoring environment allows users to identify problems at the schematic or layout phases, Mentor says. Moreover, the new platform for non-specialist PCB engineers delivers accurate concurrent design analysis and verification, and comprehensive tool integration.

“Our most recent research shows that the broad use of analysis and verification throughout the design phase directly supports engineering management’s efforts to compress the design cycle while improving board system quality,” said Chad Jackson, president and principal analyst, Lifecycle Insights. “Mentor's advancements in PCB design simulation solutions is a critical enabler to such efforts, and managers should take a hard look at these offerings."

The Xpedition verification platform is designed for non-specialist PCB designers to enable quick and intuitive simulation and analysis functions. Launched within the designer’s authoring tool, integrated verification technologies provide automatic model creation, concurrent simulation, cross probing from results, and error reviews within a single environment.

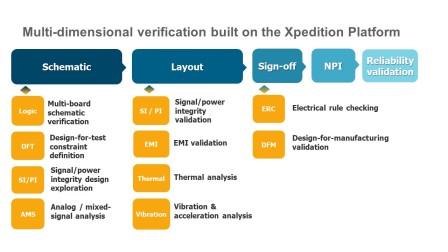

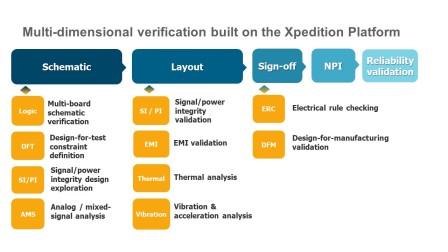

The Xpedition platform is comprised of a range of technologies: schematic analysis, signal integrity (SI) and power integrity (PI) analysis, electrical rule checking (ERC), thermal simulation, vibration analysis, design-for-fab (DfF), assembly (DfA) and test (DfT) manufacturability testing. These integrated technologies, applied within a single authoring environment familiar to the designer or design team, provide early virtual design prototypes. The new Xpedition platform introduces a comprehensive, multi-dimensional solution for upfront design verification, from concept to design hand-off for assured manufacturability.

The verification platform incorporates a new, fully automated schematic integrity tool to replace manual visual schematic inspection, said to eliminate respins early in the design by as much as 70%. And it features design-for-test analysis, which identifies test point requirements that are automatically passed from schematic design to layout as constraints to improve testability coverage. This feature creates test and inspection outputs for machines in process preparation with early diagnostics, thereby lowering the overall cost of testing.

According to David Wiens, Xpedition product marketing manager, this is the culmination of technology that was developed for the manufacturing floor. "Engineers ran it on the back-end. Then it moved more into the design process and is now tightly integrated (in Xpedition). There's a new engine integrated into the flow at the schematic stage. The basic premise is, engineers look for problems on testability after layout is done. They sprinkle some test points around, and the board goes to electrical test but has low coverage on design. It passes, but then goes to functional test where they realize it doesn’t operate because in the original test phase there wasn't good coverage."

Other improved integrations in the new Xpedition platform include comprehensive DFM analysis covering fabrication, assembly, test, flex/rigid-flex, substrate and panel validation early and concurrently during PCB design, without leaving the layout in the new Xpedition integration environment; and electrical performance sign-off, specifically automatic electrical rule checking (ERC) that quickly identifies critical signal integrity, power integrity and EMI/EMC issues concurrently with PCB layout, potentially accelerating design reviews from days to minutes.

“Recognizing that systems design complexity continues to increase, one of Mentor’s key initiatives is to empower our customers with industry-leading verification technologies, which have been historically leveraged in specialized, or discrete instances,” stated A.J. Incorvaia, senior vice president, Mentor Electronic Board Systems. “With our new Xpedition platform targeting PCB designers, these integrated solutions enable verification within the design process to ease deployment, accelerate time-to-results, and allow our customers to maximize their investments.”

The Xpedition verification platform is now available, and the suite of Mentor tools supports most non-Mentor design flows.

For more information, visit mentor.com/pcb/xpedition, see the YouTube video, download the technology white paper, or view the webinar.