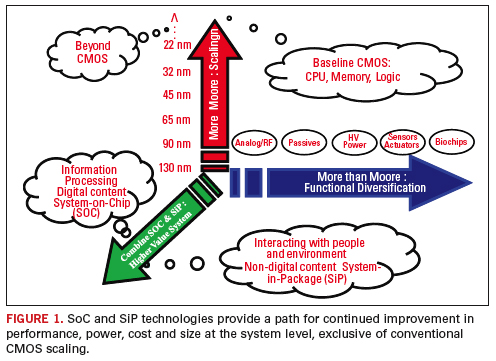

SiP-based system-level integration resolves CMOS scaling limits.

The electronics industry is nearing the limits of traditional CMOS

scaling. Although predictions that Moore’s Law has reached its limits

have been heard for years, they have proved premature. We are now,

however, nearing the basic physical limits to CMOS scaling, and the

price elastic growth of the industry can no longer continue based

solely on Moore’s Law scaling. New materials and device architectures

in development will eventually provide a path to increased density,

increased performance and lower cost beyond the capability of

CMOS-based circuits. However, there will be a time lapse between the

slowing of traditional CMOS scaling and the rollout of architectures

and materials that can support Moore’s Law scaling. In the meantime, as

scaling become more difficult, packaging innovations are taking up the

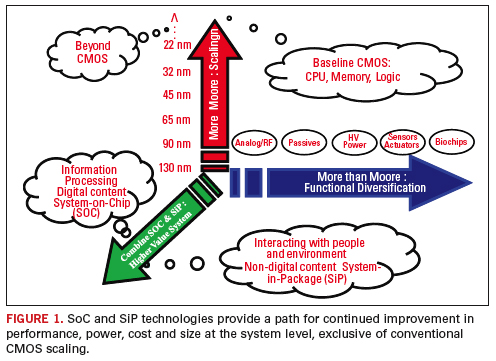

slack (Figure 1).

The

International Technology Roadmap for Semiconductors (ITRS) defines

functional diversification, incorporating system-level functions into a

single package, as “more than Moore.” This approach enables continued

rapid progress in functional density during a period where traditional

CMOS scaling cannot keep the pace and new architectures are not yet

ready. A second key contribution of packaging to maintaining the pace

of functional density scaling is 3-D integration. Both these

innovations are accomplished through integration of multiple circuit

types into a single device using system-on-chip (SoC) and

system-in-package (SiP) technologies. As electronics becomes more

consumer-dominated, the most important of these will be SiP. ITRS

defines SiP as “a combination of multiple active electronic components

of different functionality, assembled in a single unit that provides

multiple functions associated with a system or sub-system. SiPs may

optionally contain passives, MEMS, optical components and other

packages and devices.”

SiP technology enables the

efficient use of three dimensions through innovation in packaging and

interconnect. The result supports continued increased functional

density and decreased cost per function. Although there will be some

applications where SoC represents the better alternative, SiP provides

advantages over SoC in most market segments. The importance of these

advantages varies with different applications. They include:

- Small and custom form factors.

- Decreased weight.

- Reduced power consumption.

- High functional density.

- High frequency operation.

- Large memory capacity.

- High reliability.

- Low package cost.

- Lower development cost, greater integration flexibility, lower NRE cost and lower product cost compared to SoC.

- Rapid time to market.

- Wireless connectivity (GPS, Bluetooth, cellular, etc.).

SiP

is not a replacement for the high-level, single-chip, silicon

integration of SoC. It is complementary, and some complex SiP products

will contain SoC components. SiP technology is evolving from a

specialty used in a narrow set of applications, to a high-volume

technology with wide-ranging impact on electronics. The broadest

adoption of SiP to date has been for stacked memory/logic devices and

small modules used to integrate mixed-signal devices and passives. Both

these applications are driving high volume in very cost-competitive

markets. SiP has rapidly penetrated many market segments, including

consumer electronics, mobile devices, automotive controls and sensors,

computing, networking, communications and medical electronics. SiP’s

benefits vary by market segment but share some elements.

Time-to-market, size, power requirements and cost have resulted in

SiP’s strongest initial penetration: mobile communications. Unit

shipments have been rising at approximately 25% per year, and this

growth is forecast to continue.

Challenges for SiP

Traditional

single-chip packaging and system-level interconnect have limitations in

interconnect density, thermal management, bandwidth and signal

integrity that can be met only with new approaches. SiP technology is

the most important new technology to address these limitations.

Nonetheless, there are still a number of challenges, the most critical

of which are:

- Interconnection capable of maintaining power integrity for actives.

- Performance

and reliability of electronic systems are limited by the ability of

on-chip and off-chip system-level interconnections to maintain power

integrity during operation.

- Interconnect inductance,

high current requirements, increasing frequency and decreasing

operating voltage all increase the difficulty.

SiP

technology enables improvement in each of these parameters, but

challenges must be addressed if SiP is to meet its potential.

Thermal

dissipation. Inadequate thermal dissipation imposes the most serious

bottleneck to SiP performance. Not only does the thermal dissipation

technology dictate the chip junction temperature and subsequently its

performance, but the thermal technology’s size and cost will limit

packaging density, size and cost of SiP-based products. Thermal

dissipation is also the key limiter to 3-D stacking of microprocessors

and other high power/density ICs.

Signal bandwidth.

Even though bandwidth is often better than for single-chip packages,

inadequate chip I/O bandwidth is the third serious challenge to the

realization of ultimate performance. Losses resulting from package

substrate properties, crosstalk and impedance mismatches are

exacerbated as off-chip bandwidth per channel increases and signal

noise budgets decrease. Perhaps the greatest issue is the inability of

the small transistor to drive off chip impedance at high speed. SiP

technologies address these limitations and offer major improvements,

but much development work remains.

SiP Evolution

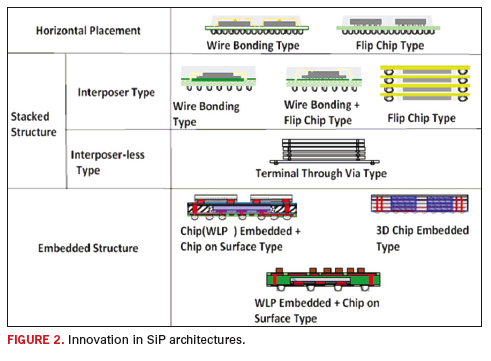

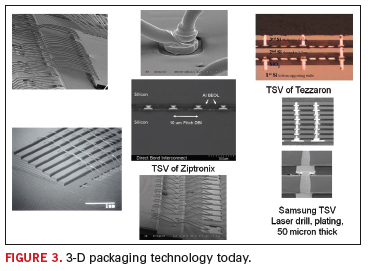

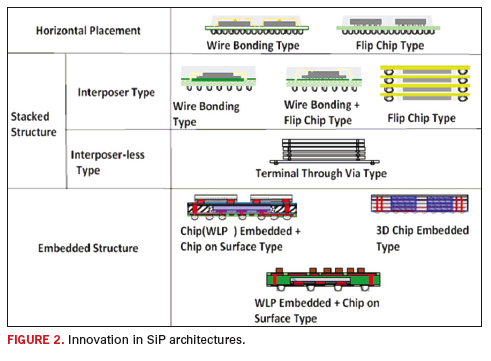

SiP

technology builds from the state-of-the-art in single-chip packaging,

with its advanced wirebond and flip-chip processes, by integrating new

technologies to support system-level integration. Emerging technologies

that will be combined with this base include wafer-level packaging, die

stacking, package stacking, through-silicon vias (TSV), 3-D packaging,

printable circuits, thinned wafers, and embedded actives and passives.

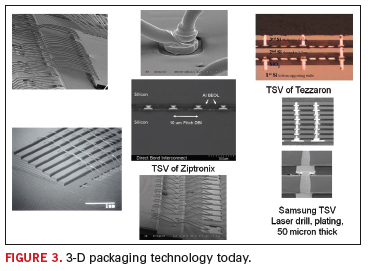

The current technical solutions for 3-D packaging include wire bonding,

face-to-face bonding and multilayer TSV structures (Figure 3).

Combining

these technologies into SiP devices provides a mechanism for

cost-effective functional diversification. These technologies enable

SiP to provide the necessary continuous increase in functional density

and decrease in cost per function. Market demands will result in the

integration of more components (e.g. passives, MEMS, optical and even

bio components) into a single package. The long-term vision for SiP is

the optimized heterogeneous integration of wireless, optical, fluidic,

bio elements/interfaces, as well as integrated shielding and heat

sinks. This goal requires new materials and control of their

interactions on the micrometer and nanometer scale.

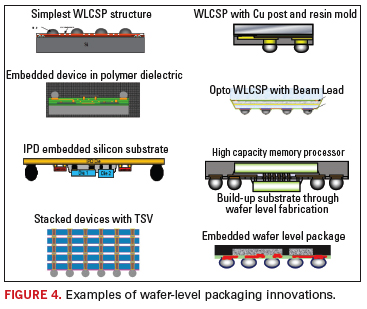

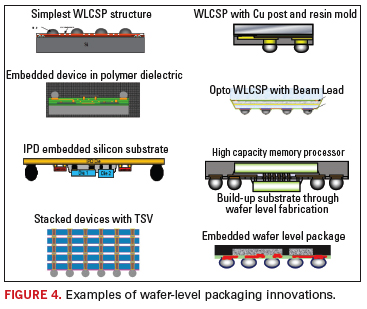

Numerous

concepts for 3-D SiP packaging are emerging, driven largely by the

demands of portable consumer products. One of the most important is

wafer-level packaging. WLP is an emerging technology, used for both

single-chip packaging and SiP, where all elements of a package are

within the boundary of the die and all packaging processes performed

prior to wafer singulation into individual circuits. WLP development

was motivated by the recognition that WLP technology (i.e., parallel

processing on the wafer) addresses the need to increase performance and

functionality, while reducing system size, power and cost. WLP

technology with and without a redistribution layer (RDL) is used for a

variety of products where the small size, thickness and weight are

important product differentiators. This technology will provide

significant cost reductions as it matures and production volume

increases.

The combination of WLP and wafer/die

stacking approaches leads to a large number of variations in WLP

technology used for SiP. The highest levels of integration are achieved

through 3-D packaging. Die stacking has been used for consumer products

(such as cellphones) for several years, with wire bonding used to

connect the stacks to the package substrates. An important new

technology is through-silicon vias, which allow more efficient die

stacking and 3-D integration. These developments lead to more complex

packages for both single and multi-die WLPs (Figure 4).

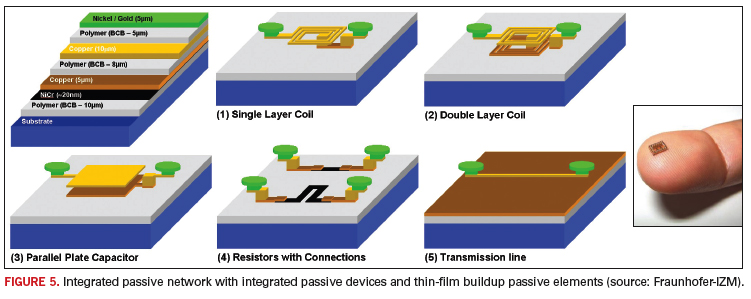

The

use of TSV as a base for SiP requires solutions for both the thermal

density associated with a “cube” of transistors (rather than the planar

array of traditional CMOS) and the incorporation of passive devices

required for system-level integration. Prototypes have been developed

addressing both requirements. Microfluidic components with a form

factor suitable for lamination into a device stack with TSV

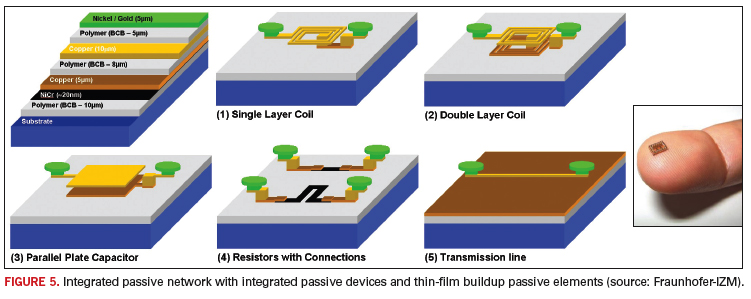

interconnect have been fabricated. Passive networks have also been

fabricated that are compatible with TSV interconnected die stacks (Figure 5).

Innovations

in SiP and WLP technologies depend on the integration of progress in

the integration of materials and equipment made in all segments of the

industry. The successful integration of all of these elements provides

a rich portfolio of capabilities in the era of “more Moore” (continued

CMOS scaling) and “more than Moore” (the addition of functional

diversification). Some of these advanced packaging elements include:

- New

materials such as nanoparticles to lower processing temperatures and

nanotubes for improved thermal and electrical conductivity.

- High-density, low-cost packaging substrates.

- Wafer thinning, singulation and handling.

- Embedded and integrated passives and actives.

- Co-design tools.

- Equipment for advanced packaging.

Innovations

in SiP have been accelerating, as this technology becomes a major

enabler for a large class of products in the consumer-driven

marketplace. Many issues remain that require continued research and

development. Today we have not proven the reliability of package-level

system integration for complex systems; we do not have a proven

strategy for repair and rework of SiP-based products; and we have not

resolved the test access and test contactor challenges associated with

the high frequency of future devices that will exceed 15 GT/s.

As

3-D SiP packaging architectures evolve, advanced co-design tools linked

with modeling and simulation capability must be in place to facilitate

an effective collaborative environment between system, device and

packaging engineers. New materials must be developed to meet the

requirements of these new SiP architectures and for meeting (changing)

environmental regulatory requirements. As an integrator of components

and technologies from different areas, SiP will become the primary

architecture for high-value, system-level products for consumer

products, before proliferating into products in all major market

segments. PCD&F

Dr. W.R. (Bill) Bottoms

is chairman and CEO of NanoNexus (nanonexus.com) and chairs the

Packaging Technology Working Group (TWG) for the iNEMI Roadmap and the

ITRS Roadmap for Assembly and Packaging; This email address is being protected from spambots. You need JavaScript enabled to view it..