New paste materials and advances in screen-printing equipment create a flexible opportunity.

It has always been an industry vision to build electronic circuits

on a substrate by means of a simple printing process. It could be one

of the reasons why they were named printed circuit boards. This vision

has finally been realized by screen printing conductive pastes onto

flexible substrates.

In the early era, this

technology was applied only to low-technology circuits because screen

printing was a low-resolution process not capable of fine-line

circuitization, and there was a lower reliability in the material sets

used. Instead, the wet etching process with photolithography that uses

copper-clad laminate materials has been employed as the manufacturing

process of fine-line and complicated, patterned PCBs for the growing

electronics industry.

From its inception in the early

1950s, flexible printed circuit manufacturing has been an interactive

process changing to encompass new materials, equipment and the demands

of customers to package more functionality at a reduced cost. The first

applications were military aircraft and missiles where reliability,

reduced size and weight and the ability to conform to packaging

structures were of prime importance. These early applications were far

less dependent on meeting cost goals than the consumer electronics

market that predominates today’s flex usage. As the market has evolved,

so have the manufacturing processes to meet these changing demands.

Some of the earliest flexible printed circuits were made by screening a

conductive paste onto a dielectric base. However, reliability concerns

by the military led to the adoption of photolithography on copper-clad

substrates as the industry standard. In recent years, a re-emergence of

the printing process to mass produce electronic circuits has started to

gain favor, as the need to cut production costs continues to drive

technical advances in the interconnect industry. Various processes,

including printing etch resists on copper substrates to dot matrix

deposition and screen printing conductive materials on dielectric base

films, have been developed or refined. The circuit density capability

of volume production processing has always been the limiting factor.

Printable Electronics Materials

Recently,

researchers and engineers have been reevaluating the printing process

as a new electronic manufacturing process because of the capabilities

it offers that cannot be achieved by wet chemical and photolithographic

methods. A lot of new organic base materials have been developed as the

substrate for printable electronics in the last five years. Several

material companies have commercialized “nano paste” products that can

be used as conductive material to make fine traces. And yet, many

researchers have been developing new supplemental materials. They can

incorporate more functions than the simple copper foil conductors

etched by the photolithography process. They can incorporate the

characteristics of high-resistance materials, high-dielectric constant

materials, Piezo effect materials, semiconductor materials, electronic

luminescence materials and more.

These new

materials can be applied by a simple screen-printing processes to

create more electronic functions on the substrates. Currently, only

limited quantities of circuits with special constructions are in

commercial use at the high-volume production level. The reason is lower

resolution and a limited ability to manufacture multilayer circuits

compared to traditional photolithography processes. Specifically, no

basic printing process has been established for multilayer fine

flexible circuits with micro via-hole connections.

Advanced Screen-Printing Technologies

A

series of advanced screen-printing processes have been developed as the

basic manufacturing technology of “Printable Electronics” by DKN

Research and NY Industry. The new processes provide equivalent or more

capabilities to build complicated circuit constructions compared to

traditional subtractive process of copper foils or laminates with the

photolithography.

An optimized combination of the

process condition and material can generate 30 micron line/space on the

thin flexible substrates. Supplemental processes are capable of

generating 80 micron via holes for double-sided and multilayer

circuits.

The basic flow of the advanced screen-printing processes is the same as the traditional screen-printing process as shown in Figure 1.

It is very simple. A paste material is printed on a thin flexible

substrate by screen printing and is baked. If necessary, supplemental

screen printing is conducted on the conductor traces. The key to this

advanced process is the optimized combination of the materials, screen

printers and screen masks. An optimized process condition generates 30

micron line/space on a thin but smooth substrate using nano-conductive

paste. Printing machines and screen masks are already capable of screen

printing 20 micron line/space. Industry is looking for capable

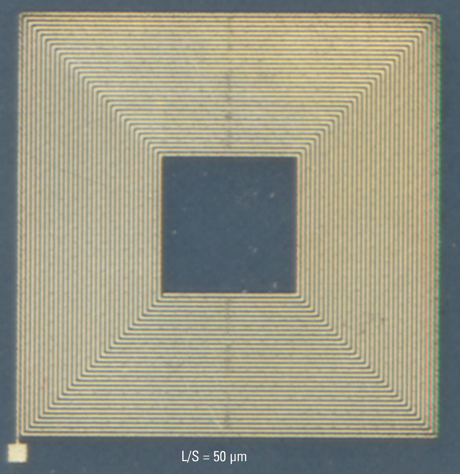

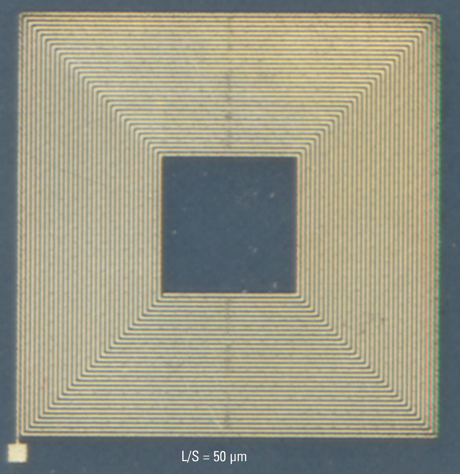

nano-conductive paste materials to realize the ultra-fine conductors. Figure 2 shows an example of a coiled circuit with a resolution of 50 micron line/space.

|

FIGURE 1. Basic process of screen printing.

|

|

FIGURE 2. Example of fine lines produced by screen printing.

|

Double and Multilayer Processes

Multiple printing processes with appropriate via-hole technologies are able to produce double-sided and multilayer circuits. Figure 3

shows one of the via-hole generation processes for double-sided

circuits. First, a conductor paste is screen printed on a thin plastic

film as the first conductor layer. Second, small holes are drilled on

the conductor pads. The piercing machine with a CCD alignment system

minimizes the shifts to less than 50 microns. Third, the second

conductor layer is screen printed on the other side of the first

conductor layer. One more screen printing of the conductor paste is

conducted to make via-hole reliability higher.

|

FIGURE 3. Double-sided process with drilled via holes.

|

Figure 4 shows the buildup process of the advanced

screen printing to add more conductor layers on the basic constructions

of the flexible circuits. An insulation layer is screen printed on the

conductor layer with small access openings followed by another screen

printing of the conductor paste. The screen printer with a charge

couple device (CCD) alignment system minimizes the shifts between the

layers.

|

FIGURE 4. Build-up process with printed via holes.

|

Creating Additional Functionality

The advanced printing process creates more functions than copper

foil circuits produced by the traditional etching process. The printing

process is able to produce not only conductors on substrates but also

dielectrics, capacitors, resistors, coils, diodes, transistors,

electroluminescence devices and more as the embedded components in the

multilayer circuit. Some of the ideas are illustrated in Figures 5 and 6.

The resistor elements can be formed between two pads of the conductor

layer by screen printing a high-resistance material such as carbon

paste. High accuracies of the resistances were made by trimming carbon

patterns. The capacitance elements need a two-step screen-printing

process to generate the conductor layer. The capacitance materials with

high dielectric constants are screen printed between the two electrodes

that have been previously generated by a separate screen-printing step.

|

FIGURE 5. Screen-printed resistors followed by trimming.

|

|

FIGURE 6. Screen-printed capacitors.

|

Material Selections

Materials are the key to

good performance of the functional printed circuits made by advanced

screen-printing processes. Depending on the intended application, there

are a broad range of material choices for each function with printable

electronics. Each material has qualities that must be matched to meet

the requirements of the environment in which it will be used (Table 1 [PDF format]).

Following

material selection, the printing process is adjusted to meet the design

parameters of these materials and the requirements of the final

applications. Various types of screen masks are imaged by using the

customer’s Gerber data to form the circuit patterns, along with the

requisite positioning datum points, so that proper alignment can be

maintained. Ink selection is critical, matching conductive particulate

size and viscosity of the suspension medium. As the line width of the

circuit decreases, the particle size needs to be reduced, at times to

less than 3 microns, to minimize the chance that an open can occur

because of no conductivity between particles within a trace.

Figure 7 shows an example of the material

selections for the circuit design. The resistance of the conductors is

proportional to the length of the traces and inversely proportional to

the width and thickness of the traces. Substrate materials make few

contributions on the physical performances of the screen-printed

traces. Nano pastes shows about three times higher conductivity for the

traces compared to the traditional silver paste. Appropriate correction

factors should be provided for patterns finer than 100 micron traces.

The electrical performances are not proportional in these ranges. The

properties will need to be measured for each design.

|

FIGURE 7. Conductivities of the screen-printed traces. (Conductor thickness: 3 microns.)

|

Table 2 [PDF format] indicates the processing capabilities of the advanced screen printing to produce high-density, flexible circuits.

Combinations with Other Devices

The

technical capabilities of advanced screen printing are quite broad.

Flex fabricators can build many kinds of constructions for the

functional printed circuits without the help of other technologies.

However, appropriate combinations with other circuit technologies and

materials will generate more value.

Figure 8 shows an example of the membrane switches.

A simple screen-printing process has been used that produces a large

volume of membrane switches for the keyboards of electronic products.

|

FIGURE 8. Switch construction made by screen printing.

|

Figure 9 shows ACP (anisotropic conductive paste)

termination of the flexible circuits with the other circuit devices. An

ACP material is screen printed on one side of the device. Then, two

devices are layered together with bond pile, and appropriate pressure

and heat are added to complete the connections. An optimized

combination of the ACP material and process condition is capable of

making reliable connections of the flexible circuits with 150 micron

pitches.

|

FIGURE 9. Interconnection of flexible circuits by screen-printable anisotropic conductive paste.

|

Figure 10 shows a unique idea of a lighting system

built on a thin, flexible substrate. All of the active and insulation

layers are formed on a transparent ITO (indium tin oxide) film by

screen printing. It is indicating a great possibility of large-size

flexible displays with low cost.

|

FIGURE 10. Electroluminecsence device built with a screen-printing process.

|

Applications

The combinations of these new

technologies will be valuable in producing new ideas for

next-generation electronics products such as switching modules, sensor

modules, bendable area light sources, thin flat speakers, flexible

displays, RF devices, small-size antennas, disposable medical devices

and more. New screen printable electronic materials will create more

application ideas in the future.

RTR (Roll to Roll) Capabilities

Most of the printing and piercing processes are technically ready to be

applied to RTR processes that have high productivity for the volume

productions. The use of high accuracy CCD alignment systems will

increase the overall process yields of multiple screen-printing

processes.

Conclusion

Screen

printing is not a new technology in the printed circuit industry.

However, the combination of new paste materials and the advanced

screen-printing process have created additional opportunities in

printable flexible electronics that cannot be made by the traditional

photolithography processes beginning with copper foil coated

substrates. More ideas will continue to be generated with these new

materials for specific applications. Multiple RTR processing will add

value to advanced screen printing by achieving low-cost manufacturing

for many flexible electronics components. PCD&F

Robert Turunen (This email address is being protected from spambots. You need JavaScript enabled to view it.) is vice president of new business development of DKN Research, Haverhill, Massachusetts. Masafumi Nakayama (This email address is being protected from spambots. You need JavaScript enabled to view it.) is president of NY Industry, Ohtsu, Japan. Dominique Numakura (This email address is being protected from spambots. You need JavaScript enabled to view it.) is managing director of DKN Research, Haverhill, Massachusetts.