µPILR technology can reduce the standoff between the PCB and the

bottom package and increase mechanical board-level reliability,

improving drop-test performance.

The past decade has seen a tremendous market demand for driving more

and more functionality into applications in the mobile space. The cell

phone is a prime example of this trend as our daily communication,

computing and consumer electronics needs merge from discreet, handheld

units into one multifunctional device.

The basic cell

phone took off in the 1990s as a novelty with voice only. The

introduction of the color screen in 2000 and the camera module in 2002

were innovative developments that dramatically changed the way we view

our mobile devices. Several other applications have been integrated,

and today, our cell phones offer advanced functions such as digital TV,

GPS, MP3 technology and more security as we search the web, enabling

our on-the-go lifestyles. The integration and miniaturization of all

components within the device has become a necessity to achieve the

reduced form factor and weight demanded by consumers.

The

silicon stacking industry has seen many revolutions, with memory

stacking for a memory subsystem to system-in-package (SiP) with the

inclusion of logic devices. Die stacking logic and memory was a quick

way of initially achieving the desired form factor, but the cost was

not sustainable long term due to the compound yield loss of the total

package. In 2005, the introduction of package-on-package (PoP) into the

industry allowed the logic and memory sub-system packages to be tested

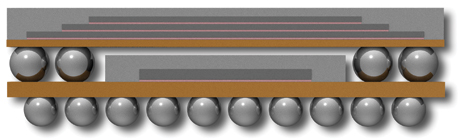

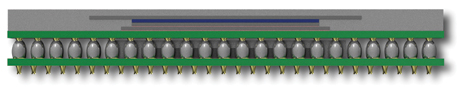

separately and reduce the cost. Figure 1 shows an

illustration of the production PoP in mobile phones today. PoP

technologies have become a main standard for these applications,

allowing designers to match technological advancements in functionality

with increasingly smaller form factors. This article will discuss two

main approaches for miniaturizing PoP via finer pitch: memory

sub-system package stacked on package with one logic die or two logic

die.

|

FIGURE 1. Illustration of the production PoP in mobile phones today.

|

Market Trends for Package-on-Package

The

current industry standard for the PoP inter-package ball-out interface

is at 0.65-mm ball pitch, and package sizes range from 11 mm x 11 mm to

16 mm x 16 mm with varying architectures. The bottom package (for the

processor) is 0.5-mm pitch with a custom ball-out based on the

processors.

Tessera recently conducted a study to

evaluate pitch trends for the logic IC in mobile applications from 2003

to 2007. The study examined 110 mobile phone teardowns from

Portelligent (portelligent.com). In 2003, approximately 30% of these

ICs were at 0.5-mm pitch, and the rest ranged up to 0.8-mm pitch.

Today, over 98% of these logic ICs are now at 0.5-mm pitch.

The

increasing number of applications in mobile devices and subsequent

higher performance demands require higher pin counts, which typically

increases size. This requires the footprint to remain the same or

become smaller. Accommodating these higher pin counts in such a

footprint will require smaller pitch. There are several ways the

industry is reducing or maintaining the overall footprint. This article

will discuss two main approaches when dealing with PoP stacking.

The

first option is to reduce the solder ball pitch, which reduces the

packages X-Y size. Logic IC packages are trending toward 0.4-mm pitch,

driving the top memory sub-system package to reduce from the current

0.65 mm to 0.5-mm pitch. This option will achieve a smaller package

size of the one component as its performance increases from one

generation to the next.

The second option allows

for higher integration while maintaining or reducing the solder ball

pitch and, in return, reducing the overall footprint of two or more

packages into one. Stacking a second logic IC into the bottom package

will increase the package size for the PoP but will reduce the overall

combined size of the two separate packages (one stand-alone logic

package and one PoP). This option will also increase the I/O count, and

the package can remain at 0.5-mm pitch to maintain good routing or

reduce to 0.4-mm pitch for size benefits. In either case, the top

memory sub-system package can remain at 0.65-mm pitch to maintain the

memory interface I/O count for the larger package.

PoP Challenges with New Market Trends

These

two PoP approaches will enable increased integration and reduced

overall form factor to allow for continued increases in performance and

applications in mobile devices. However, both options have their

challenges.

For the first option, the reduced pitch

on the top package will result in smaller clearance between the two

packages. A logic die can be connected to its substrate via wire bond

or flip chip. Currently, the clearance between two packages using

either interconnection method for 0.65-mm pitch is approximately 0.270

mm to 0.320 mm. When the top package pitch is reduced to 0.5 mm, the

clearance will reduce to approximately 0.220 mm due to the smaller

solder ball used for this smaller pitch. In turn, this will require

reduced height in the logic IC. Reducing the height for wire-bonded die

would mean die thinning to ≤75 µm and/or reducing the wire bond loop

height. Reducing flip-chip height will also require die thinning and/or

reduce the bump height. There is also a cost premium associated with

lower wire-bond loop heights, and reduced mechanical reliability for

lower bump heights for flip chips. All these solutions increase

performance risk and cost due to die thinning and handling.

The

second option – stacking two logic die in the bottom package – will

require an increased clearance between the two packages. Increasing

solder ball size to achieve this increased clearance will require

higher pitch for the memory sub-system to avoid solder bridging. In

addition, the higher pitch will reduce the I/O count for the

package-to-package interface if the same X-Y size is to be maintained.

These

challenges are difficult to overcome within the current technology

window while maintaining the cost and risk targets. The industry is

examining innovative new approaches to take packaging technology to the

next level. One new option is the Micro Pin Interconnect Layer (µPILR)

technology developed by Tessera, which addresses many of these

challenges.

µPILR Technology for PoP

The

µPILR technology platform utilizes conical-shaped, solid copper

contacts plated with nickel/copper. This can be used in multiple types

of interconnections:

1. IC-to-package substrate interconnections

2. Package-to-PCB and/or PoP interconnections

3. Interlayer via connections within package substrates, flexible printed circuits or high-density PCBs.

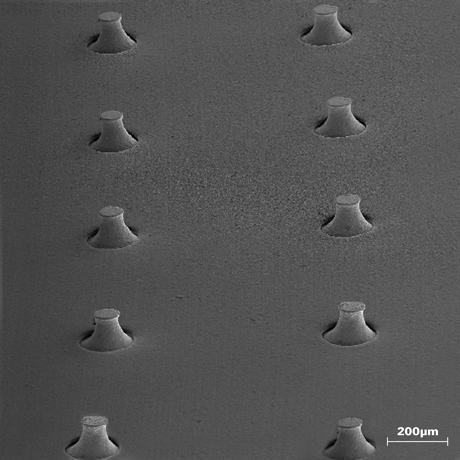

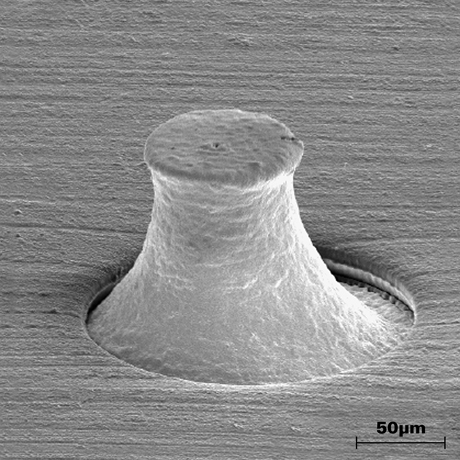

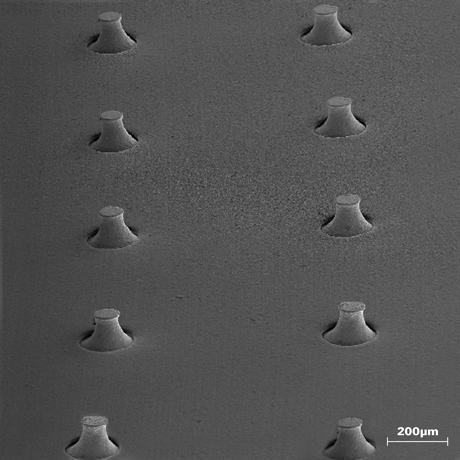

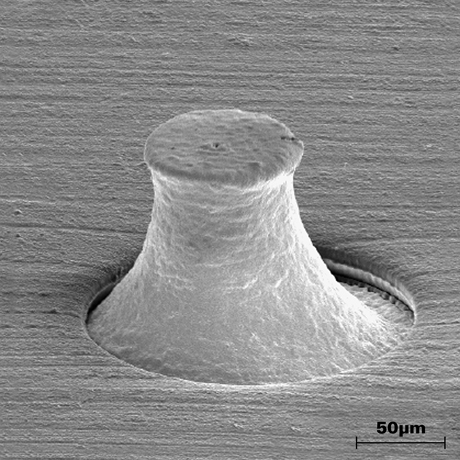

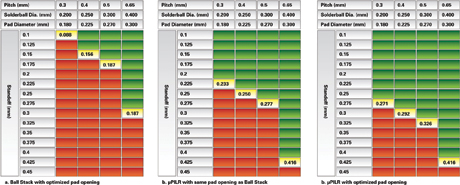

Figures 2a and 2b

show SEM images of this contact. This article will mainly discuss the

package-to-package and PCB-to-package interconnections for PoP.

|

FIGURE 2a. SEM image of a µPILRTM contact (125 µm height with 80 µm tip).

|

|

FIGURE 2b. SEM image (higher magnification) of a µPILR contact (125 µm height with 80 µm tip).

|

The

introduction of the solid copper contact within a solder joint provides

better ability to control and hold standoff while maintaining solder

interconnect reliability at the board and package-to-package level of

the PoP.

This technology can reduce the standoff

between the PCB and the bottom package by more than 50% to allow

overall package height reduction. Due to the increased surface area

between the copper and solder when using µPILR, there is an increase in

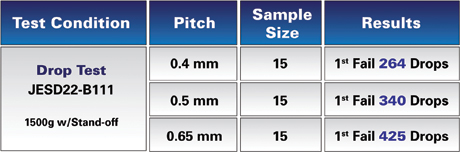

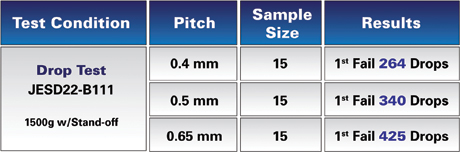

mechanical board-level reliability, especially drop test. Figure 3

illustrates initial drop test data where the addition of the copper pin

shows late first failures using JESD22-B111 drop test conditions. The

test vehicle for the data was on a 10 mm x 10 mm package size with the

full area populated with µPILR contacts. The drop test was performed on

this test vehicle with multiple pitches – 0.65 mm, 0.5 mm and 0.4 mm –

using 196, 324 and 529 total µPILR contacts, respectively. To simulate

an actual device, the silicon size used was 6.5 mm x 6.5 mm x 150 µm.

This was attached to the top surface of the substrate using paste die

attached material. The overmold height for the package was 450 µm over

the substrate.

|

FIGURE 3. Drop test data using µPILR showing first failures for 0.4 mm, 0.5 mm and 0.65 mm pitch.

|

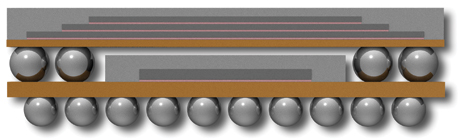

A theoretical stack-up analysis of the test vehicle (shown in Figure 4)

using the tolerance stacking methodology shows that less than 1.2 mm

total height can be achieved. The test vehicle consists of one die in a

bottom package at 0.4-mm pitch, three die in the top package at 0.5-mm

pitch µPILR and a two-layer µPILR substrate (top and bottom).

The

ability of µPILR to control standoff at the package-to-package

interconnect level allows for higher clearance between the two packages

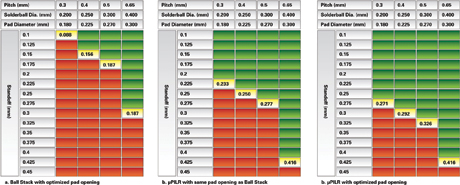

while maintaining the needed finer pitch. Figure 5

(left and middle side) shows the difference between the resulting

standoffs for solder ball and µPILR PoP, respectively, at the

package-to-package interface using the same solder ball diameter and

pad opening. Figure 5 (right side) also shows the resulting standoff

with a smaller solder ball and pad opening.

|

FIGURE 4. Test Vehicle for µPILR PoP with one logic and three memory die at <1.2 mm total package height.

|

|

FIGURE 5. Inter-package stand-off of PoP using solder balls only versus µPILR with solder. Inclusion of µPILR increases joint stand-off.

|

This

data was calculated using an in-house developed software utility. This

software calculates the resulting shape of the solder (diameter and

height) based on the initial volume of solder. The final shape can be

calculated for different cases including solder reflowed on a pad,

solder ball reflowed to make the joint between two packages, or between

package and PCB. The calculations are based on the assumption that the

surface tension dominates, and hence, the free solder surface is

spherical. If the package weight per interconnect ratio is high enough,

then gravity will have a significant effect, which is not accounted for

in this tool. For standard packages, package weight/interconnect ratio

is small enough that the results from this tool are quite accurate when

compared to actual observed data.

To meet market

demands for a smaller 0.5-mm pitch at the package-to-package interface

and to keep the risk factor on the logic device as low as possible, the

desired stand-off would need to remain at approximately 0.270 mm.

Figure 5 (left side) shows that a solder ball-only solution cannot meet

this requirement unless the solder ball size is increased, which

increases the risk of solder bridging. Using µPILR, Figure 5 (middle),

allows better control of the standoff to achieve the desired clearance

by forming a column-like structure. Since µPILR can provide improved

joint reliability, the same calculation was done with a smaller pad

opening, as shown in Figure 5 on the right side. This allows for a

higher margin for the standoff. The standoff for the contact using

µPILR can be further increased by increasing the total solder volume.

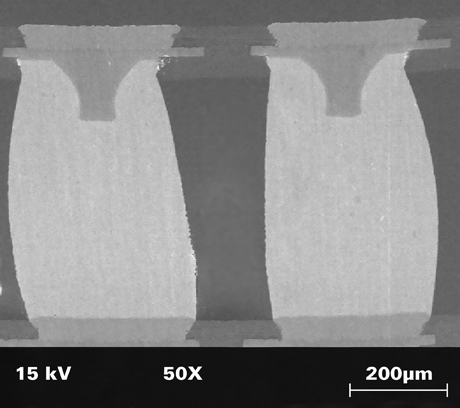

Surface-mount

experiments showed that increased solder content enables a higher

standoff at the same finer pitch without bridging, mainly because µPILR

causes the joint to form a column-like structure, which is more robust

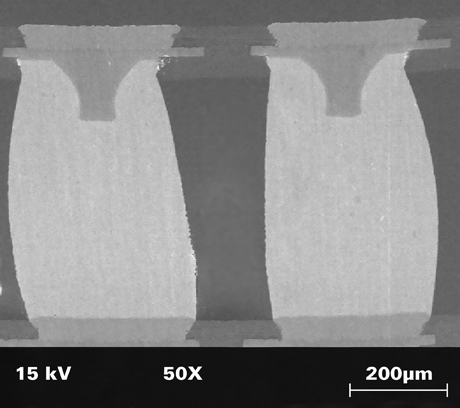

than a solder-only joint. Figure 6 shows a SEM

picture of a 0.125-mm µPILR copper pin surrounded by solder to form an

interconnect with a standoff of 0.540 mm. A clearance this high also

facilitates the second approach of stacking two logic ICs in the bottom

package of a PoP as mentioned earlier.

|

FIGURE 6. SEM picture of a 0.125 mm µPILR copper pin surrounded by solder to form and interconnect with a stand-off of 0.540 mm.

|

As

the industry continues the trend toward tighter integration in mobile

devices, stacking two logic devices in the bottom package for PoP will

allow for higher performance and smaller overall form factor. However,

this results in a thicker mold cap height on the bottom package, which

requires a larger standoff clearance between the two packages. At even

larger pitches such as 0.65 mm, solder ball interconnect cannot

overcome this mold cap height. However, by applying the concept of

increased standoff ability with the µPILR technology to this

application at 0.65-mm pitch, designers will be able to realize more

integration between the logic and memory.

Testing

will be conducted on daisy-chain test vehicles, board-level reliability

on the µPILR PoP test vehicle with one die as shown in Figure 4 at 0.5

mm, and with two die at 0.65-mm pitch in the bottom package and up to

three die in the top packages. The data will be available in late 2007

and early 2008, respectively. The test vehicle will be RoHS compliant

with a halogen-free material set. Testing will cover JEDEC JESD22-B111

for drop (1500 gn, 0.5 ms pulse, 30 drops), JEDEC JESD22-A104 Condition

G for temperature cycling (-40ËšC to +125ËšC until 63% fail, 10 minute

dwell, 10ËšC/minute ramp rate; continuous monitoring of resistance) and

JEDEC-9702 for monotonic bend test (4-Point Bend; 5000 µStrain/s).

Package

assembly with µPILR technology uses standard semiconductor assembly

equipment for all major processes, including die placement, wire

bonding and overmold. The surface-mount technology required for µPILR

is dependent on the resulting standoff needs, since the copper pins are

coated with nickel and immersion gold to allow for high-strength

adhesion of solder. If the interconnect standoff is to be minimized for

height reduction between the bottom package and PCB, for example, then

the ball attach process at package assembly can be eliminated, and the

surface mount can be performed by optimizing the solder paste content

on the PCB. The µPILR package can then be picked, placed and reflowed

in the same manner as any other component. For higher standoff

requirements, such as between packages, solder can be pre-applied to

the µPILR copper pins. Additional solder paste or solder balls can be

placed to the pad opening on the top interface of the bottom package.

The total solder content can be optimized to achieve the required

standoff for the clearance needed. Thus, surface-mount assembly can

utilize existing processes, materials and equipment without incurring

additional capital expenses.

Conclusion

Looking

ahead, logic IC packaging will reduce interconnect pitch from the

current 0.5 mm to 0.4 mm, driving technology capability toward higher

I/Os and/or smaller packages. The smaller overall package size results

in a lower I/O count for the memory interface at the current 0.65-mm

pitch. Driving the memory module to 0.5-mm pitch will either maintain

or increase the I/O count. However, 0.5-mm pitch standoff between the

logic and memory interface will increase the risks and costs with the

need to reduce thickness within the logic arena.

Technologies

of this type are being introduced to the market to allow for finer

pitch with the ability to control solder standoff, while using existing

assembly and surface-mount infrastructures. As these technologies

mature and gain broader adoption, they will serve as the catalyst to

enable future innovation in the converging mobile devices market. PCD&F

Ed. – In a follow up to this article, Printed Circuit Design & Fab will publish the data generated from the daisy-chain, board-level reliability testing when it becomes available.

Manisha Sharma is senior product marketing manager, Tessera Inc. She can be reached at This email address is being protected from spambots. You need JavaScript enabled to view it..