The objective of metallization is deposition of a continuous copper layer.

The German author Kurt Tucholski defined a hole as the following:

1. “A hole is where nothing exists.”

2. “ A hole is a permanent companion of the non-hole.”

3. “ If man sees a hole, he intends to fill it. While doing so, he often falls into it.”

Certainly,

the objective of the metalization operation is to put something into

the holes, namely a continuous, void-free and tightly adherent deposit

of copper. However, despite good intentions, one does not always

accomplish this. The result is voiding: those areas on the resin or

glass or at times both that do not receive the copper deposit.

Mention

the word “voids” in a PCB facility, and watch everyone scramble. The

problem with voids in plated through holes (PTH) is that there are so

many potential causes that it is very difficult to quickly identify the

source or sources of the problem. It is the purpose of this and the

next few columns to discuss voiding and its causes in detail.

Generally,

voiding is most often blamed on the metalization process itself.

Certainly, this process is not without blame. However, since PTH

metalization and the desmear process are so interdependent on each

other, it is easy to see that the upstream processes can influence a

defect that manifests itself later in the sequence. We will discuss

this in detail later.

The IPC-A-600 standard provides an excellent guideline with respect

to voids. Basically, if your company is building PCBs for Class 3, any

voiding is considered a nonconforming defect. This includes glass

voids, resin voids, circumferential voids ... any voids. Voids come in

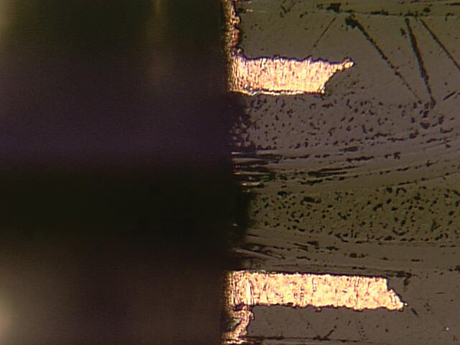

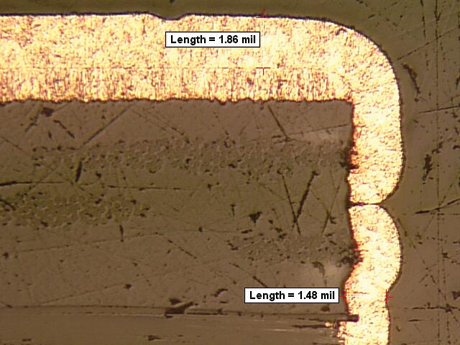

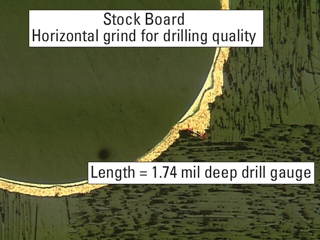

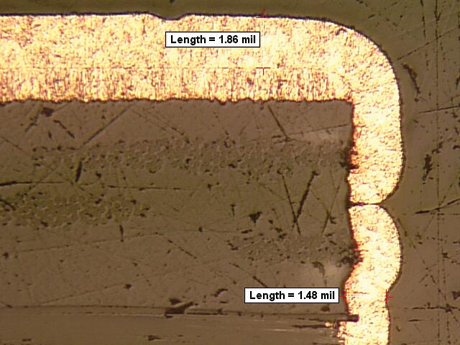

all shapes and sizes. Some are very evident, such as the one seen in FIGURE 1. Other voids are much more subtle, as shown in FIGURE 2. Basically, we strive for a continuous void-free deposit as shown in FIGURE 3.

|

FIGURE 1. Large void between the innerlayer conductors.

|

|

FIGURE 2. Smaller voids in the copper plating.

|

|

FIGURE 3. A continuous void-free deposit.

|

Assume voiding has been discovered. An analysis of the problem tells

you that the voiding is confined to the glass only. The resin coverage

looks fine. Backlight testing confirms voiding through the electroless

copper process. The voids are on multilayer PCBs made with a

tetrafunctional resin. This resin system is used regularly in the PCB

facility, so there are no new wrinkles here. Where would the

troubleshooting effort start? Let’s first discuss the possible causes

of glass voiding.

Numerous possible causes for glass voiding are listed below:

- Insufficient cleaning and conditioning of the holes

- Drill debris in holes

- Overall poor hole wall quality

- Insufficient or ineffective desmear

- Permanganate or manganate residues remaining on resin

- Insufficient catalyzation (in electroless copper preplate)

- Insufficient acceleration (leaving excess tin and not allowing palladium to initiate the deposition reaction)

- Air/gas bubbles lodging in small diameter vias

- Inadequate rinsing

- Panels racked too close together

- Rack agitation.

These are just a few of the causes of voids. One of the first places

to look is the cleaner/conditioner step. This step is critical to the

success of the electroless copper process in that the conditioner

enhances the adsorption of the activator species (palladium) to both

the resin and glass.

Inadequate conditioning will reduce the charge density on the glass

and resin, resulting in less than optimal palladium (activator

adsorption). This condition will lead to lack of a continuous void-free

copper deposit in the hole. Sufficient activator is necessary to

catalyze the electroless copper reaction.

Essentially,

the cleaner/conditioner can be described as an activator promoter.

After all the examinations are complete and the problem is minor glass

voiding, (no evidence of resin voids), then the first place to look is

the cleaner/conditioner. Generally, the concentration of the

cleaner/conditioner or the operating temperature is less than

recommended by the process supplier.

Another cause is that the useful life of the made-up solution has

been exceeded. In this case, the “spent” chemistry must be sent to

waste treatment, and a new solution made ready. If this doesn’t solve

the problem, there are other areas to look at.

Pre-Electroless Causes of Voids

|

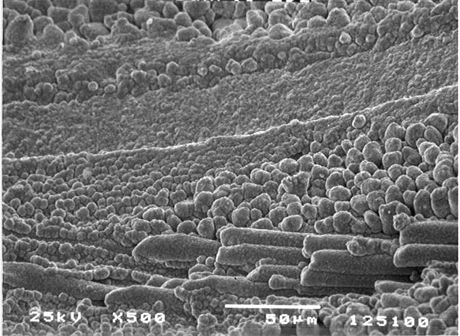

FIGURE 4. Glass fiber bundles are torn out exposing a deep gouge in the resin.

|

It is often said by seasoned engineers that there are so many

process steps and variables that could have an influence on the success

or failure of getting a continuous, void-free copper deposit in the

hole. One of the obvious causes of voids or at least poor copper

coverage is the result of poor drilling. Figure 4 shows voids

on the glass bundle fibers. A closer look as this section will show a

very poorly drilled hole wall, with glass bundles protruding from the

resin.

Astonishingly, many feel the plating process should always

compensate for such a travesty. A surface such as the one shown in

Figure 4 makes it very difficult to catalyze with the palladium-based

activator from the electroless copper process. One should immediately

investigate the drilling operation, looking at the following:

- Drill bit quality: the number of hits and the overall condition of the drill tool.

- Spindle feeds and speeds: is the drill tool punching its way through the stack?

- Slow up-feed – causing the torn out glass bundles – should be 2X the in-feed rate.

- Check chip loads: experiment with different chip loads to improve quality.

- Stack height: the number of PCBs in the drill stack; consider reducing the number to improve quality.

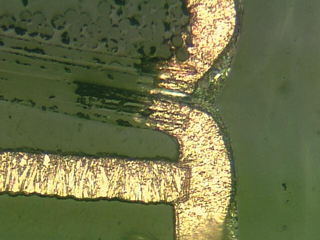

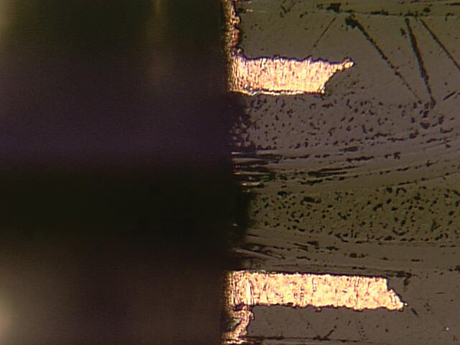

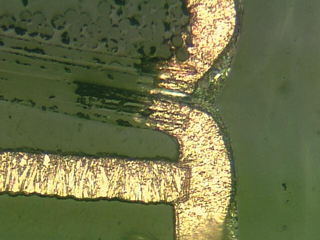

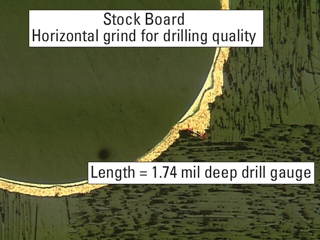

Figure 5 shows a horizontal section of a PTH. Note again the poor quality in the hole wall and its effect on the plating process.

|

FIGURE 5. Poor hole wall quality created in the drilling process can lead to voids and other plating difficulties.

|

The desmear operation is another potential cause of PTH voids. The

most effective desmear process available today is based on alkaline

permanganate. As a matter of fact, the permanganate system is

considered an industry standard. The use of alkaline permanganate for

multiplayer PCBs has had a dramatic effect on copper coverage and

adhesion in the plated through hole. However, this process, if not

controlled, can be a major cause of voids. First, the process consists

of three or four steps, as listed below that comprise the main chemical

process for desmear.

1. A solvent conditioner designed to penetrate the polymer matrix of

the resin system and weaken the polymer-polymer bonds of the cross

linked chain.

2. The alkaline permanganate solution consisting of sodium or potassium permanganate and its corresponding hydroxide salt.

3. A neutralizer (possibly in combination with glass etch) for removing manganese residues.

4. Glass etch as a separate step to lightly roughen (frost) or more

aggressively remove glass fibers that may be protruding into the hole

due to etch back.

Any of these four processes if not controlled can lead to voids. If

this is the case, even the most robust of electroless copper processes

will not be able to compensate.

|

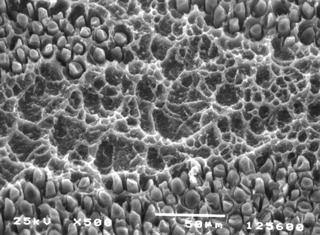

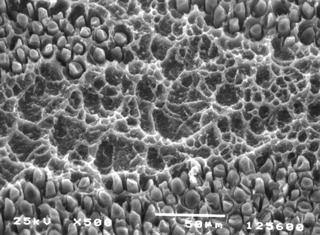

FIGURE 6.

Micro-roughened dielectric surfaces improve copper adhesion to the hole

wall and enhance catalyst adsorption to accelerate plating coverage.

|

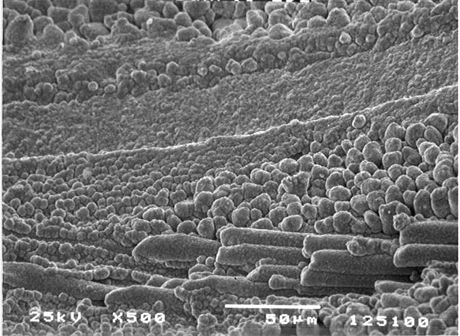

For example, the effective alkaline permanganate process not only

removes drill smear, but will micro-roughen the resin as shown in Figure 6. This texturing is often referred to as the honeycombed appearance. This is desirable for two reasons:

- The textured surface promotes palladium catalyst adsorption, which in turn promotes electroless copper deposition and coverage.

- Surface improves copper adhesion.

This, in turn, promotes improved solderability by minimizing or

eliminating the occurrence of blow holes seen in the wave-soldering

operation. More on blow holes in a future column.

Regardless, if the texturing is inadequate, the possibility of voids

exists. The main reason is that the lack of texturing will reduce

catalyst adsorption, leading to voids. Electroless copper processes

require an adequate amount of catalyst on the hole wall to promote the

electroless copper deposition. Key questions to ask in the

brainstorming session include the following.

- Is the solvent conditioner (swellant) making sufficient

penetration into the resin matrix? And is the solvent system compatible

with the resin that you are trying to desmear? It should be noted here

that some of the higher Tg resins do not react in the same manner as

standard FR-4 and require specialized solvent conditioning. The higher

the degree of cross-linking in the polymer resin makes the more

difficult it is for the solvent to penetrate and, thus, weaken the

polymer-polymer bonds in the resin. In turn, this reduces the action of

the permanganate solution in terms of resin removal and

texturing.

- Check the operating temperature of the alkaline permanganate

solution, as well as the hydroxide and actual permanganate content. The

hydroxide content aids in promoting the aggressiveness of the

permanganate attack on the resin. The permanganate in the +7 oxidation

state will perform the actual oxidization and breakdown of the resin.

Manganate (+4) is a by-product of this reaction and will not

participate in the resin oxidation. Manganate residue should be

controlled and maintained below 20 to 25 grams/liter. Otherwise, as

manganate builds up over time, the rate of resin removal and texturing

will diminish. If solvent compatibility and degree of penetration is

sufficient, then consider utilizing a higher concentration of

permanganate. Sodium permanganate will allow for more actual

permanganate in solution over the corresponding potassium salt.

- Finally, review the neutralizer and glass-etch. A major cause of

voiding is due to manganate residues remaining on the hole wall resin

and glass. One should frequently renew this solution to ensure fresh

working chemistry. Also, check the acid concentration. Lower

concentration reduces the effectiveness of the neutralization.

Often, to reduce process steps, fabricators will combine the

neutralizer and glass etch in the same process tank. (Personally, I

prefer separate steps because the process is more effective.) As the

glass etch weakens due to continued use, the ability of the glass etch

to roughen the glass fibers (referred to as “frosting”) is reduced.

This, in turn, reduces the ability of the catalyst to adhere to glass.

When this happens, voids can result. PCD&F

Michael Carano is vice president, marketing and business development at Electrochemicals Inc. He can be reached at This email address is being protected from spambots. You need JavaScript enabled to view it..