Nanoparticle inks and drop-on-demand ink jet printers offer a

unique opportunity to generate fine-line additive circuits on flexible,

three-dimensional substrates.

Ink jet printing has been gaining interest for use in electronics

manufacture. This article is intended to provide a brief overview of

ink jet printing; a review of some of the applications of

high-frequency electronics from the literature; and, finally, some

ideas as to possible further applications.

In a review of ink jet printing for graphics applications, Le

defined the technology as follows; “Ink-jet is a non-impact dot-matrix

printing technology in which droplets of ink are jetted from a small

aperture directly to a specified position on a media to create an image1.”

To

facilitate this technology, there are two general designs of ink jet

printers. The designs are continuous and drop-on-demand (DOD). As the

names imply, these designs differ in the frequency of generation of

droplets.

In continuous ink jet printers, droplets are generated continually

with an electric charge imparted to them. As shown schematically in Figure 1,

the charged droplets are ejected from a nozzle. Depending upon the

nature of the imposed electric field, the charged droplets are either

directed to the media for printing, or they are diverted to a

recirculation system. Thus, while the droplets are generated

continuously, they are directed to the media only when/where a dot is

desired.

|

FIGURE 1.

Continuous ink jet (schematic). Charged droplets leaving the nozzle are

directed either toward a substrate or toward an ink recirculation

system, depending upon the imposed electric field.

|

In DOD ink jet printers, droplets are generated only when they are

needed. The droplets can be generated by heating the ink to boil off a

droplet (so called thermal ink jet). Alternatively, the droplets can be

ejected mechanically through the application of an acoustic pulse or

electrically stimulating a piezoelectric to elicit a deformation, which

will generate a droplet as shown in Figure 2.

|

FIGURE 2.

Piezoelectric drop on demand ink jet (schematic). In a DOD ink jet

printer, upon application of a mechanical pulse, the ink chamber is

deformed. This results in the ejection of a droplet toward the

substrate.

|

An advantage of ink jet printing is its modularity. Individual

printing nozzles are combined into a single print head. Multiple print

heads can be combined within a single printer. This allows printing

more than one ink at a time (e.g., different colors). The modular

nature also allows for combining printheads laterally for use in large

area printing. Currently, a major application for ink jet printing is

in the production of billboards.

Inks for Printing Electronic Products

To apply

ink jet printing technology to electronics, the ink to be printed is

made up of electronic materials rather than the pigments used in

graphics printing. As with other fluid-based printing methods, the ink

used in ink jet printing is a complex formulation of solvents,

plasticizers and surfactants in addition to the appropriate electronic

materials. For the most part, DOD printers have been used in ink jet

printing of electronics.

Ink jet printing has been used to produce conducting and semiconducting polymers2, as well as displays3.

The work discussed here will concentrate primarily on ink jet printing

of conductors. Work has been reported on ink jet printing of copper4, silver5 and gold6.

Typically, nanoparticles of the desired conductor are dispersed in the

ink. However, due to the high surface area of copper nanoparticles,

oxidation becomes a concern. This necessitates using inks containing a

copper metal precursor, rather than copper nanoparticles. Commercially

available silver or gold inks can be obtained from several companies

such as Cabot (U.S.), Cima NanoTech (Israel/U.S.), Ulvac (Japan),

Harima Chemical (Japan) and Advanced NanoProducts (Korea). These inks

contain up to 60% by weight of metal.

The small

particle size of the nanoparticles in electronic inks allows for lower

firing temperatures to densify the printed ink. Silver nanoparticles

fired as low as 260˚C have resulted in dense films with conductivity

about 50% of bulk silver7. This low densification

temperature allows for circuits on plastic substrates that could not

otherwise handle the higher temperatures typically used to densify

metallic particles.

Ink Jet Printing for Electronic Products

There

are many advantages to employing ink jet printing for electronic

circuits, several of which are listed below. The first four are

currently being utilized. The others are potential advantages that, to

the author’s knowledge, have not yet been exploited for electronic

applications.

Digital process. Ink

jet is a dot-matrix technology, a digital process. This means that

patterning can be directly computer controlled. No masks or screens are

necessary. Changes can be made quite easily by altering the

computer-controlled pattern rather than awaiting a new mask or screen.

Additive process.

Materials are applied only where desired. This can be important when

expensive materials are being deposited. Additionally, the extra steps

and environmental concerns of stripping are eliminated with ink jet

printing.

Non-contact. The print

nozzles do not contact the substrate, preserving delicate surfaces.

They are typically positioned 0.5 to 1.0 mm above the substrate.

3-D printing. Through

programming of the individual nozzles and repeated passes, it is

possible to vary the thickness of the deposited ink with position. This

has been used in forming 3D ceramic structures8 and to print spiral conductors9.

Different materials can be printed simultaneously.

As with multicolor printing of graphics, it is possible to print

different electronic materials (e.g., conductors, resistors,

dielectrics) simultaneously. By ganging printheads containing the

different materials, it would be possible to print them in a single

pass. This could eliminate the need for pattern registration for

subsequent depositions and increase throughput.

Large sizes.

As mentioned above, ink jet printing is currently used in the graphics

world to print billboards. The same print heads that are used in

desktop printing of electronic materials can be ganged laterally to

print onto significantly larger-sized substrates. It is important to

note that this scale up is direct, that is the printheads are the same,

so that the parameters found applicable at small sizes should be usable.

For

many electronic applications, screen printing has been the preferred

deposition method. The line widths and line spacing typical of ink jet

printing are one-half those typical of screen printing: 30 µm vs. 60 µm10. Even finer geometries have been reported in developmental ink jet printing: 10 µm lines and spacing11.

While

there are advantages to ink jet printing of electronics, there are

drawbacks. The physics of generating droplets from very narrow diameter

nozzles constrains the allowable ink rheology. The ink typically needs

to have a surface tension >35 mN/m and a viscosity of 1 to 10 cPoise12.

In part because of these rheological constraints and the present

limited market, there are not many commercially available inks for

electronics. However, it is anticipated that as the market grows,

additional suppliers and ink compositions will become available.

High-Frequency Applications

Reports of ink jet printing used in high-frequency electronics are

reviewed below to give a sense of the breadth of applications possible.

Radio-controlled watch module. Seiko

Epson has reported fabricating 20 metal layer circuit boards of 200 µm

thickness (not including the base polyimide substrate) by ink jet

printing using a piezoelectric DOD printer13. The boards

measured 20 x 20 mm. Silver conductor lines and vias were ink jet

printed as were the interlayer dielectrics. The silver conductor lines

were 4 µm thick and 50 µm wide with a minimum spacing of 110 µm. No

details of firing conditions were reported.

By using

this technology, the module size for radio-controlled watches was

reduced by 65% over a chip-on-board (COB) process using a glass-epoxy

substrate. The ink jet PCB contained all of the passive components

except for the antenna, connector and crystal.

Co-planar waveguides in PCBs. Joint

work carried out by Motorola and the University of Illinois (Chicago)

studied the possibility of using ink jet printing to form PCBs. For one

of the test vehicles, they used a DOD printer to fabricate coplanar

waveguides consisting of silver transmission lines between copper

etched ground planes and signal pads on polyimide14. The conductor line was densified by heating at 300˚C for 15 min. Their lines were 120 to 200 µm wide and 1 to 3 µm thick.

The resistivity of the conductor lines was 3.5 x 10-5 Ωcm.

They

found good, repeatable electrical results between 0 to 4 GHz. They also

found that test vehicles subjected to 85% humidity and 85°C for up to

172 hours showed an average increase of only 4% in the resistivity of

ink jet printed silver conductors on polyimide.

RFID components.

Researchers at the University of California–Berkeley have been active

in fabricating RFID components via ink jet printing. They have printed

nanoparticles of gold onto polyester, creating spiral inductors and

conductors using a DOD printer15. To improve the uniformity

of the printed conductors, they overlaid drops of ink with 5 to 15 µm

spacing. They then printed several lines on top of each other. To

further increase line uniformity, they printed with the substrate

heated to 160˚ to 190˚C.

Using their print

conditions, the best results were found for printing three layers or

more. The resultant conductors were about 160 µm wide and had

resistivity as low as 23 mΩ/n. They also used ink jet printing to

deposit polyimide dielectrics for crossovers and capacitors. Pin-hole

free dielectric films were formed as thin as 340 nm and as thick as 3

µm. Spiral inductors of 350 nH were formed with three printed layers of

gold. The inductors had radii of 5,000 µm with line widths of 160 µm

and line spacing of 100 µm.

Transmission lines for cell phones. Nokia

has investigated the possibility of using ink jet printed conductors on

polymers for possible use in cell phones and other electronic devices.

They printed silver nanoparticles onto polymer substrates using a DOD

printer16. They printed several different sized conducting

traces and cured them in an infrared oven. For thin conductor lines

(<10 µm), they found the optimal curing conditions to be 240˚C for

60 min.

To test the electrical parameters of the

ink, they fabricated 50 Ω transmission lines on ceramic substrates.

They compared transmission lines with ink jet printed silver conductors

to etched copper lines. The line width and length were the same for the

two conductors. The thickness of the ink jet printed conductor was 2

µm, while that of the etched copper was 17 µm. The insertion losses

between 0 to 5 GHz were slightly larger for the ink jet printed silver

conductor but were judged to be acceptable.

Future Applications

Hopefully,

the applications described above demonstrate the applicability of ink

jet printing for high-frequency electronic products.

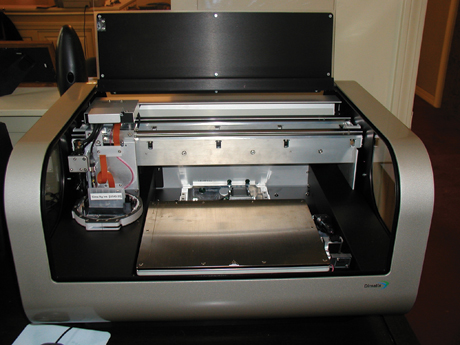

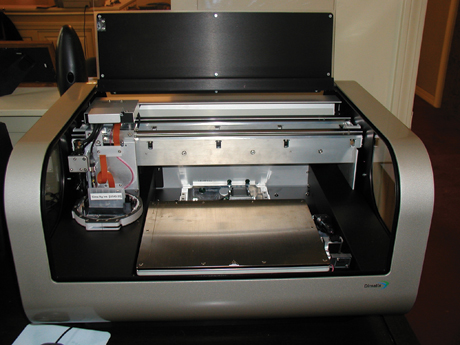

Using a tabletop dedicated materials deposition system from Dimatix17, shown in Figure 3,

product development on additional applications of ink jet printing is

ongoing at Advanced Materials Solutions. The Dimatix system has a 200 x

300 mm printing area with a vacuum platen that is heatable to 60°C. The

system has integrated fiducial and drop watcher cameras. It can be used

to print Ag and AgCu conductors onto Mylar, ceramic and textile

substrates.

|

FIGURE 3.

Tabletop dedicated materials deposition system. The PC-controlled DOD

ink jet materials deposition system from Dimatix has a 200 x 300 mm

printing area and uses replaceable cartridges.

|

The printer uses replaceable cartridges, which avoids any cross

contamination of inks. The cartridges have silicon MEMS printheads

containing 16 independently controllable nozzles. The printhead can be

heated up to 70°C. The nozzles have 21 µm orifices and 254 µm spacing

(100 dpi). The cartridges are user fillable. The following applications

are under development.

Quickturn Antenna Prototypes

As has been

described, ink jet printing is a digital process. No masking is

necessary, only a digital file. This could lead to quick production of

prototypes, such as antennas. It would allow for a quick turnaround for

changes. We envision an iterative process in which a prototype can be

printed from a digital file, tested and proposed changes to the pattern

introduced digitally. This cycle would then be repeated until the

desired characteristics were obtained. Delays associated with waiting

for new masking or screens to be produced could be eliminated while

optimizing the design.

Conformable Circuits

Ink

jet printing can be performed on flexible substrates. These substrates

could be bonded to a non-planar surface to permit conformable circuits.

(It should be pointed out that the flexibility of the densified

conductor traces has not yet been demonstrated.) Alternatively, with a

change of fixturing, it may be possible to print directly onto

non-planar surfaces.

Circuits on E-Textiles

E-Textiles are textiles into which metal wires are woven. There has been work done on using these for transmission lines18.

By ink jet printing additional conductors and passive components, more

advanced capabilities can be built-in with the integral conductors

acting as interconnects. Potential applications include wearable

electronics (e.g. GPS or antennas), physiological monitors and animal

monitoring via RFID. Conductive traces have been successfully

demonstrated on E-textiles via ink jet printing19.

Conclusion

This

article was designed to provide an introduction to the applicability of

ink jet printing in the electronics industry. The utility for several

high-frequency applications has been demonstrated. It is hoped that

this article will stimulate the reader to consider other possible

applications of this exciting technique. PCD&F

John Blum is Principle, Advanced Materials Solutions LLC. He can be contacted at This email address is being protected from spambots. You need JavaScript enabled to view it..

References

1. H.P. Le, Progress and Trends in Ink-jet Printing Technology, Journal of Imaging Science and Technology, Vol. 42, No. 1, pp. 49-62, [1998].

2. B.J. de Gans, P.C. Duineveld, U.S. Schubert, Inkjet Printing of Polymers: State of the Art and Future Developments, Advanced Materials, Vol. 16, No. 3, pp. 203-213, [2004].

3. M.L. Chabinyc, W. S. Wong. A.C. Arias, S. Ready, R.A. Lujan, J.H.

Daniel, B. Krusor, R.B. Apte, A. Salleo, and R.A. Street, Printing

Methods and Materials for Large-Area Electronic Devices, Proceedings of the IEEE, Vol. 93, No. 8, pp. 1491-1499, [2005].

4. G.G. Rozenberg, E. Bresler, S.P. Speakman, C. Jeynes, and J.H.G.

Steinke, Patterned low temperature copper-rich deposits using inkjet

printing, Applied Physics Letters, Vol. 81, No. 27, pp. 5249-5251, [2002].

5. P.J. Smith, D.Y. Shin, J.E. Stringer, B. Derby, and N. Reis, Direct

ink-jet printing and low temperature conversion of conductive silver

patterns, Journal of Materials Science, Vol. 41, pp. 4153-4158, [2006].

6. J. Chung, S. Ko, N.R. Bieri, C.P. Grigoropoulos, and D. Poulikakos,

Conductor microstructures by laser curing of printed gold nanopartricle

inks, Applied Physics Letters, Vol. 84, No. 5, pp. 801-803, [2004].

7. D. Kim, S. Jeong, J. Moon, and K. Kang, Ink-Jet Printing of Silver Conductive Tracks on Flexible Substrates, Molecular Crystals and Liquid Crystals, Vol. 459, 45/[325] – 55[335], [2006].

8. K.A.M. Seerden, N. Reis, J.R.G Evans, P.S. Grant, J.W. Halloran, and

B. Derby, Ink-Jet Printing of Wax-Based Alumina Suspensions, Journal of the American Ceramic Society, Vol. 84, No. 11, pp. 2514-2520 [2001].

9. J. Mei, M.R. Lovell, and M.H. Mickle, Formulation and Processing of

Novel Conductive Solution Inks in Continuous Inkjet Printing of 3-D

Electric Circuits, IEEE Transactions on Electronics Packaging Manufacturing, vol. 28, No. 3, pp. 265-273, [2005].

10. K. Kowai, Y. Kawamura, H. Nagata, S. Yamaguchi, T. Sakuma, K.

Sakurada, T. Kobayashi, and K. Wada, Low Temperature Co-fired Ceramics

Multi-layer Substrate Utilized with Ink-jet Printed Silver Layers, Proceedings of the 38th International Symposium on Microelectronics (IMAPS), pp. 823-833, [2005].

11. K. Murata, J. Matsumoto, A Tezuka, Y. Matsuba, H. Yokoyama,

Super-fine ink-jet printing: toward the minimal manufacturing system, Microsystems Technology, Vol. 12, pp. 2-7, [2005].

12. M.D. Croucher and M.L. Hair, Design Criteria and Future Directions in Inkjet Technology, Industrial & Engineering Chemistry Research, Vol. 28, pp. 1712-1718, [1989].

13. H. Imai, S. Mizuno, A. Makabe K. Sakurada, K. Wada, Application of Inkjet Printing Technology to Electro Packaging, Proceedings of the 39th International Symposium on Microelectronics (IMAPS), pp. 484-490, [2006].

14. J.B. Szczech, C.M. Megaridis, D.R. Gamota, and J. Zhang, Fine-Line

Conductor Manufacturing Using Drop-on Demand PZT Printing Technology, IEEE Transactions on Electronics Packaging Manufacturing, Vol. 25, No. 1, pp. 26-33, [2002].

15. D. Redinger, S. Molesa, S. Yin, R. Farschi, and V. Subramanian, An Ink-Jet-Deposited Passive Component Process for RFID, IEEE Transactions on Electron Devices, Vol. 51, No. 12, pp. 1978-1983, [2004].

16. Z. Radivojevic, K. Andersson, K. Hashizume, M. Heino, M. Mantysalo,

P. Mansikkamaki, Y. Matsuba, and N. Terada, Optimised Curing of Silver

Ink Jet Based Printed Traces, Proceedings of the International Workshop on Thermal Investigations of ICs and Systems (THERMINIC), pp. 163-168, [2006].

17. Model 2831; FUJIFILM Dimatix, 2230 Martin Ave, Santa Clara CA 95050.

18. D. Cottet, J. Grzyb, T. Kirstein, and G. Troster, Electrical Characterization of Textile Transmission Lines, IEEE Transactions on Advanced Packaging, Vol. 26, No. 2, pp. 182-190, [2003].

19. J.B. Blum, Fabric Based Electronics, presented at Vermont EPSCOR Annual Conference, Burlington VT, [2007].