Via fill for via-in-pad designs improves manufacturability from board fab through assembly.

High density interconnect (HDI) and microvia technology have been

commercially available for years, but many sectors of the electronics

design and manufacturing community have historically regarded these as

alternatives that should not be pursued until absolutely necessary.

Concerns with higher complexity design processes, expensive performance

qualification tests and lower assembly yields have hindered the

adoption due to fears of increased product costs.

While

all these factors generally apply to any new technology, they also

usually get worked out as the technology matures. The mass production

of portable electronic products such as mobile phones, personal digital

assistants (PDAs) and music players--all of which we could not enjoy

without this enabling technology--have provided ample opportunities for

the relevant issues to surface and be addressed. Yet, some technology

sectors are still reluctant to adopt HDI. Ironically, we communicate

our concerns about HDI technology over devices that employ it.

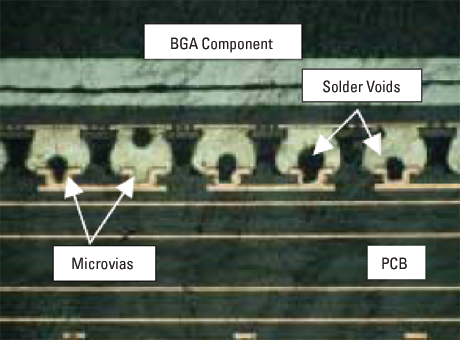

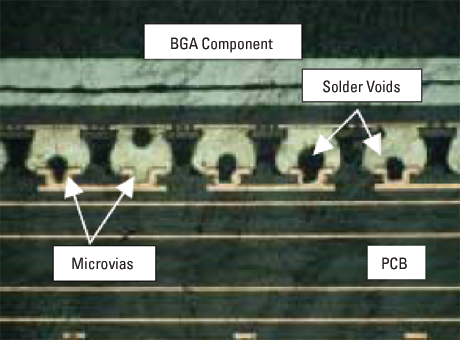

Microvias, as indicated by their name, are very small vias, usually

ranging from less than 6 mils or 150 microns in diameter down to 2 mils

(50 microns) or less. They are typically located near the centers of

the PCB pads and can be seen under magnification as small dimples or

depressions in the pad. Figure 1 shows a 10-mil pad with a 4-mil microvia.

|

FIGURE 1. Pads with and without a blind microvia.

|

The past four or five years have seen the emergence of many more

devices that require the use of microvias in all types of applications,

even those demanding long-term reliability performance. In some cases,

they are impossible to avoid, as the desired semiconductor chips are

only available in packages that require microvia-in-pad technology on

the PCB. In other cases, such as advanced aerospace applications,

package size and weight cannot be increased, despite the ongoing need

for improved electronic processing performance. The point of acceptance

for the technology step is eventually reached and crossed.

Embracing HDI and microvia technology can bring many benefits, the most

notable of which include significant reductions in layer count, smaller

circuit areas, higher component counts, thinner boards, shorter design

times and, ultimately, less expensive material constructions. But there

is no such thing as a free lunch, and such gains do not come without

some real technology challenges to both the fabricator and the

assembler. Historically, microvia-in-pad designs have presented plating

difficulties to fabricators and soldering difficulties to assemblers.

On the plating front, using conventional PCB fabrication processes and

equipment, a blind microvia size of 2 mils (50 microns) or even 4 mils

(100 microns) can present significant challenges with regard to

wetting, plating and other processing. The following types of defects

have been known to result:

- Breakdown in the continuity of the base copper metallization (voids)

- Incomplete coverage of the final surface finish due to contamination

- Voiding due to etch out of the electroplated copper as a result of incomplete or porous electrolytic tin-etch resist coverage

- Entrapped corrosive process chemistries resulting from poor rinsing and drying

On the assembly side, microvias present a separate set of

challenges. It has been documented that in the case of small discretes

like 0402s or 0201s, the parts can rob solder from the joint being

formed, raising reliability concerns. The bigger concern, however, is

the issue of voiding when microvias are in the pads of area array

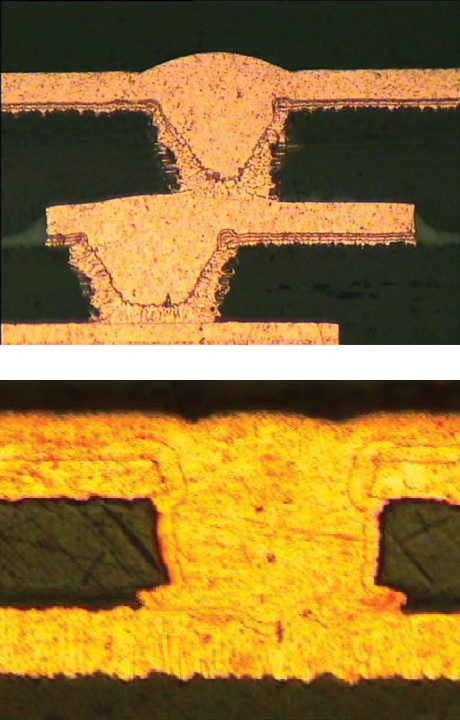

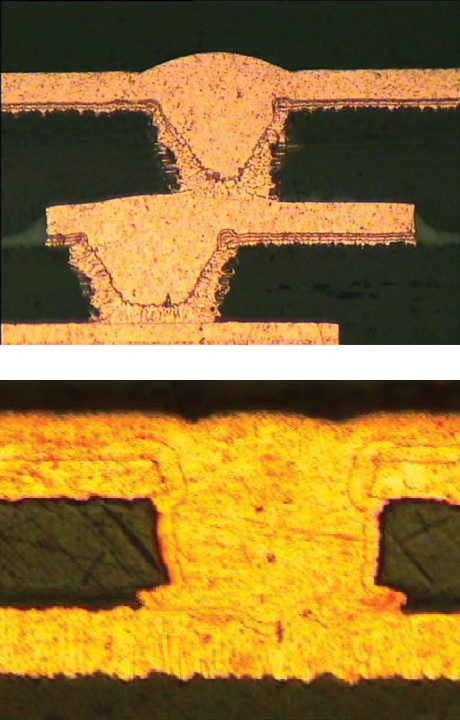

devices, such as microBGA-style components. Figure 2

shows a cross section of an area array device with microvias in every

pad. Considerable voiding is observed in these joints. These large

voids occur because the depression in the pad surface traps air during

the solder paste printing portion of the assembly process.

|

FIGURE 2. Typical cross section of microvia-induced solder voids.

|

The correlation of void size to the reliability of BGAs is a

long-standing point of contention in the assembly community. Most

assemblers avoid the debate but subscribe to the position that the

smaller and fewer the voids, the better. A print-reflow process that

runs typical maximum void size rates in the neighborhood of 5% can see

that number soar to 25% and higher when microvias are introduced. From

this, only about 5% can be attributed to the solder paste, with the

remaining 20% coming from the microvia itself. These numbers can alarm

any engineer associated with the success of the product under

consideration, regardless of his or her general position on void size

and reliability! To make matters worse, the leakage of entrapped

moisture or residual contaminants in these relatively inaccessible

blind via-holes during or after the fabrication process can provide

additional contributions to void formation.

The voiding issues encountered at board-level assembly are

nondiscriminatory with respect to the final solderable finish of the

PCB. They manifest themselves on all of them, but not always in the

same exact way. The low rate of spread of lead-free solders on copper

OSP finishes result in a void that does not move within the solder

joint; the trapped air stays in its original location within the

microvia. The higher rates of spread of the same solder alloy on ENIG

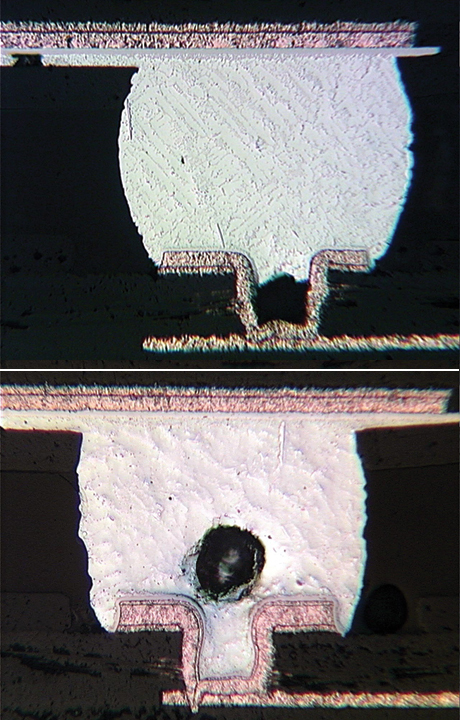

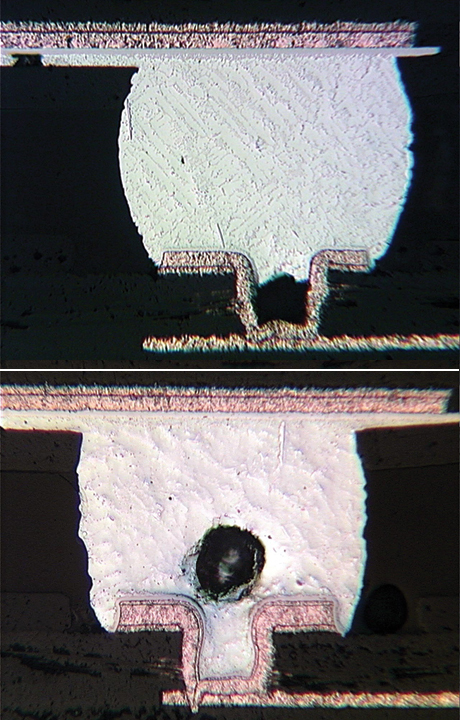

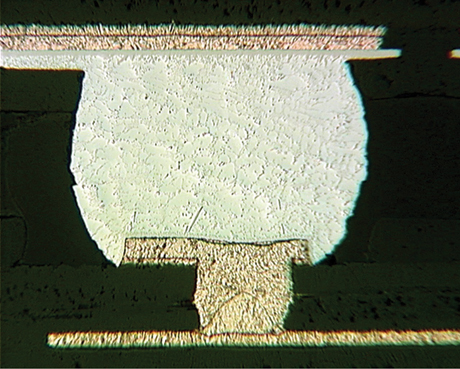

finish helps to liberate the trapped air into the bulk of the joint. Figure 3

shows two similar 0.5-mm pitch CABGA (Chip Array Ball Grid Array)

solder joints with unfilled 4-mil vias in their pads. The one on the

left has an OSP final finish; the one on the right has an ENIG final

finish. The debate regarding the optimum location of the void within

the joint continues, but the general opinion leans toward containing it

within the via, as seen on the OSP finish.

|

FIGURE 3. BGA solder joints with microvias on an OSP finish (left) and on an ENIG finish (right).

|

The bad news here is that microvias in pads help to produce very

large voids in very small solder joints. The good news in this case is

that there are relatively simple solutions at hand. A range of

via-filling technologies is available to the fabricator. These include:

- Inorganic thick-film pastes

- Organic pastes including unfilled, metal filled and inorganic filled types

- Electrolytic copper plated via-fill

All

these via-fill methods can improve structural integrity and provide

varying degrees of enhanced thermal relief. However, whereas the

processes that use pastes are typically suited to larger through-hole

vias (>10 mils or 0.25 mm diameter), processes that use plated

copper are more suitable options for smaller, blind microvias (<7

mils or <175 microns diameter).

The copper

filling of vias can benefit design performance by improving thermal

conductivity, providing a known CTE compatibility with the board

metallization and readily supporting “stacked via” designs. But the

benefits don’t end there. For the fabricator, some of the available

copper via fill processes offer simultaneous conformal plating of the

through holes while achieving complete filling of the microvias, thus

eliminating the unwanted, additional process steps associated with

paste filling processes. And for the assembler, if the pads do not have

the small, deep air-trapping wells on their surface, the issue of

excessive voiding is practically eliminated.

There

is a further advantage here for the fabricator. The technology that

plates through holes while simultaneously filling blind microvias is a

simple one that drops into existing vertical electrolytic plating lines

using soluble copper anodes. The concept and application are described

as follows.

Simple Copper Via Fill Process

Electrolytic

copper baths that are based on a sulfuric acid and copper sulfate

typically contain “brightener” or additive systems, which incorporate

an activator and a suppressor, plus other components. Such single-step

processes are typically more difficult to control, as the analysis

involves more complex CVS (cyclic voltammetric stripping) techniques to

measure the multiple components. However, the copper process utilized

in this study does not contain any activator in the electrolytic step.

Instead, the proprietary1

process actually works on a simple two-step system where the PCBs are

first pre-dipped in an activator bath before transferring to the

plating cell that contains the suppressor. At start-up of the plating

cycle, the adsorbed activator from the pre-dip is already concentrated

in the lower current density areas, i.e. within the blind microvia

recesses. As plating progresses, the larger and slower moving

suppressor molecules restrict any excessive and unwanted copper

deposition on the panel outer-surfaces, which results in fast and

efficient filling of the microvias. The use of the two separate baths

make CVS control much more precise.

Additionally, the

total organic levels in the plating bath are moderated, therefore

improving the physical integrity of the copper deposit and its

resistance to cracking under thermal shock conditions. The copper

deposited by this process meets and exceeds all the standard deposit

performance test requirements for through-hole metallization, showing

typical elongation values of 28% and tensile strengths of 44,000 psi

(304 N/mm2). These values are well in excess of IPC-6012B minimums, which are cited as 12% elongation and 36,000 psi (248 N/mm2).2

This simple two-step process is operated in a standard, vertical DC,

air-agitated plating cell, thereby eliminating the need for any

specialized equipment3. A schematic diagram of the via-filling mechanism is shown in Figure 4.

|

FIGURE 4. Simple two-step via filling mechanism.

|

The bath composition for the Copper Via Fill (CVF) process is typically 100 g/l H2SO4, 50 g/l Copper as Cu2+; 70 mg/l Cl–

and 1.0 ml/l CVF inhibitor. The anodes used are standard phosphorized

copper (0.03 to 0.08% phosphorous) in basket or bar form. The plating

sequence is nominally 15 minutes at 0.75 Amps/dm2 (7 Amps/ft2) followed by a ramp up to 1.5 to 1.9 Amps/dm2 (14-18 Amps/ft2) for 60 to 90 minutes, depending on the microvia depths and aspect ratios.

The use of the step-ramped current4

ensures that the initial copper deposition along the via hole walls

enhances the plating current distribution to the microvia base, further

improving the “bottom-up” via fill efficiency and eliminating any

cavities. Under such conditions, the through holes can also be plated

with good throwing power (e.g. 5:1 AR plating at 80 to 85% throwing

power using a three-point measurement method for the hole wall vs.

surface thickness).

Definition of Via Filling Efficiency and Through-Hole Plating Efficiency

The Via Fill Yields (VFY) and through-hole metallization (PTH) metrics are calculated as shown in Figure 5.

The VFY takes into account not only the percentage of fill of the

microvia, but also the thickness of the plated copper on top of the

board and (in case of incomplete fill) the fill angle (B). The smaller

this fill angle, the easier it will be to fill the microvia with solder

or resin without air entrapment. Typically, yield values over 5%

represent good fill. For the through holes, the objective is usually

PTH > 80%. Some representative via-fills are seen in Figure 6.

|

FIGURE 5. Via fill and PTH efficiency.

|

|

FIGURE 6. Some typical via-fill results from the two-step system.

|

As illustrated, the solderable surfaces of the pads no longer have

deep wells to trap air. Limiting the contribution of the microvia to

solder joint void formation has been the topic of many studies, and

there are several methods available to minimize the microvia’s

contribution.

Published Studies on Microvia Voiding

Several earlier studies on microvias and voiding have been published previously in 20035,6,7

and showed, among other findings, that copper-filled microvias

exhibited the best results in reducing voiding. Vias that were

completely filled showed less voiding than vias that were partially

filled, presumably because less entrapped air creates fewer voids.

Smaller via sizes were seen to create smaller voids than larger vias.

On the assembly side, soak profiles produced fewer voids than ramp

profiles. These studies were performed prior to the introduction of

low-voiding solder paste formulations.

The findings

of these studies provided an excellent basis for an investigation that

began in 2004 and finished up in late 2006. This study, which used the

simple two-step copper via fill technique previously described,

examined the effects of:

- Via presence and size

- Alloy system (tin-lead or lead-free)

- PCB finish

- Via filling

The complete report of the study8 can be obtained from the Surface

Mount Technology Association Web site (smta.org). Some key findings

from the study are discussed below.

Via Presence and Size

The test vehicle in the DOE was designed to compare pads with no vias,

4-mil vias, and 6-mil vias side-by-side on the same assembly. As

anticipated, the fewest voids were produced on pads with no vias at

all. More were produced on pads with 4-mil unfilled vias, and the most

were produced on pads with unfilled 6-mil vias.

Alloy System

Both

tin-lead and SAC305 alloy systems were used in the study. No mixed

metals were investigated. Devices with eutectic tin-lead balls were

soldered with tin-lead solder paste; likewise, devices with SAC305

balls were reflowed with SAC305 solder paste.

For

all four device types used in the study, the lead-free system performed

equivalently or slightly better with respect to void production. The

performance difference between lead-free and tin-lead was not

substantial, but the trend was consistent. This is an important fact to

note, because for many years, lead-free solder pastes were believed to

produce more voids than tin-lead. This was the case early in the

lead-free transition, when paste formulators were still climbing a

steep region of the learning curve. Most formulators now have at least

five years of lead-free experience under their belts, and modern

generation lead-free pastes can often rival the best-in-class

characteristics of their tin-lead predecessors in nearly every

performance category.

PCB Finish

Three

surface finishes were included in the study: OSP, ENIG and immersion

silver (ImAg). OSP and ImAg generally produced similar amounts of voids

that were less frequent and smaller than those produced with ENIG

finish.

Effect of Via Filling

The most remarkable result was the effect of filling the vias with

copper. The investigators found it impossible to differentiate the

voiding performance between filled vias and pads with no vias at all,

regardless of device type or alloy system. The charts in Figures 7 and 8 show the voiding behavior of 0.8-mm FlexBGA devices.

|

FIGURE 7. Voiding comparison of pads with no vias, pads with filled vias and pads with unfilled vias soldered with tin-lead solder paste.

|

|

FIGURE 8. A similar comparison on jointed soldered with lead-free solder paste.

|

As shown here, it is easy to visually differentiate the performance

of the unfilled vias from the other two test conditions. But it is not

so easy to discern a performance difference between the pads without

vias and the ones that had the vias filled. The data from these two

conditions were analyzed statistically, and it was determined that with

95% statistical significance, the voiding rates produced on pads with

filled microvias are equal to the voiding rates produced on pads with

no vias at all.

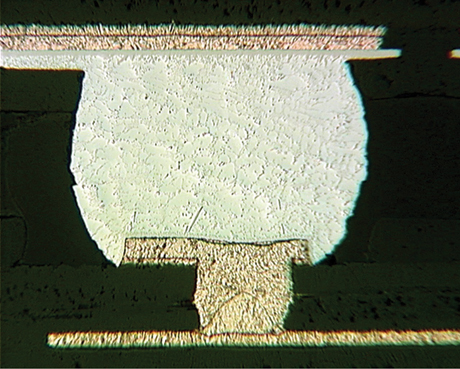

A cross section of a filled microvia is shown in Figure 9.

The via is filled with copper, and the surface of the pad is nearly

planar. There is no room for air to get trapped during the printing

process, thus no contribution from the microvia to solder void

production, and no concerns regarding void location based on final

finish.

|

FIGURE 9. A 0.5 mm-CABGA with copper filled microvia.

|

Conclusions

HDI and microvia-in-pad technologies

have enabled the continuous migration to smaller, lighter, more

powerful electronics by enabling finer pitch I/Os, thinner circuit

boards and higher routing densities. For many years, their application

was relatively limited to portable devices, as high reliability and

high performance applications have not been nearly as eager to adopt

this technology as the portable providers. Today, HDI and

microvia-in-pad technologies are becoming more mainstream and (welcome

or not) are quickly becoming a fact of life for many designers and

assemblers, regardless of the end product they produce.

As with any forward step in technology, hurdles must be cleared on the

path to maturation. For many fabricators, those hurdles included

plating impediments, additional process steps and added cost. For

assemblers, those hurdles included solder joint starvation, solder

joint voiding and overall reliability concerns for the end product.

Many

of these concerns have been addressed, and numerous methods of

resolution are available. The specific solution of filling the vias

with copper plating in the same process as PTH plating tackles concerns

on three fronts: it provides better thermal and electrical design

characteristics when compared to existing technologies; it reduces

process steps in fabrication; and it eliminates excessive voiding in

board-level assembly. And it does it all within relatively short

plating times while offering simplified and consistent methods of

process control. Given that the major obstacles have been cleared, a

broad spectrum of electronics sectors can now employ HDI and

microvia-in-pad technologies and enjoy the cost and performance

benefits that they bring to the end product. PCD&F

Chrys Shea is R&D Applications Engineering Manager, Cookson Electronics Assembly Materials. She can be reached at This email address is being protected from spambots. You need JavaScript enabled to view it.. David Ormerod is Business Director, PWB Metallization, Enthone Inc. He can be reached at This email address is being protected from spambots. You need JavaScript enabled to view it..

Acknowledgements

The

most recent study cited above was a two year endeavor, and this article

is based on the findings of this activity. Many thanks to the

contributors of this study: Rahul Raut and Lou Picchione of Cookson

Electronics; Quyen Chu and Nicholas Tokotch of Jabil Circuit; and Dr.

Paul Wang of Microsoft.

References

1. Japanese patent application JP20002 19994(A); European patent application EP1152071A1.

2. IPC-6012B, Qualification and Performance Specification for Rigid Printed Boards, IPC, Bannockburn, IL, 2007.

3. Verbunt, D. Isik, U. Schmergel, Dr. J. Rasmussen: “Optimized

Vertical Process for Microvia Filling and Through Hole Metallization

under Production-like Conditions”, IPC, Anaheim, February 2005.

4. “Simultaneous Microvia Filling and Through-Hole Metallization,” A.Lachowicz et al, CPCA Proceedings, March 2006.

5. Grano, F, et al, “Impact of Micro-Via in Pad Design on Void Formation,” Proceedings of SMTA International, September 2003.

6. Harjinder, L. and Sundar, S, “Assembly Issues with Microvia

Technologies,” Proceedings of SMTA International, September 2003.

7. Singer, et al, “The Effect of Via-In-Pad Via Fill on Solder Joint Void Formation,” Proceedings of IPC Works, October 2003

8. Shea, et al, “BGA Solder Void Correlation to Via-In-Pad, Via Fill,

Surface Finish, and Lead-Free Solder – Final Report,” Proceedings of

the Pan Pacific Microelectronics Symposium, January 2007.