Filled via-in-pad processes are a way to achieve an intermediate density increase for a minimal additional cost.

In PCB design, via refers to a plated hole that connects copper

tracks from one layer of the board to other layers. High-density

multilayer PCBs may have blind vias, which are visible only on one

surface, or buried vias, which are visible on neither and are normally

referred to as microvias. The advent and extensive use of finer pitch

devices and requirements for smaller size PCBs creates new challenges.

An exciting solution to these challenges uses a recent, but common PCB

manufacturing technology with a self-descriptive name: via-in-pad.

Via-in-pad

technology is becoming a more essential and efficient strategy. With

certain parts, the component manufacturer strongly recommends it.

However, surface-mount assembly engineers like vias placed away from

component lands to prevent solder migration. Increases in board

thickness due to higher I/O array packages complicate these issues as

larger holes and pads may be required to maintain through-hole

reliability.

Other design factors such as placing

passive devices directly under packages are creating the need for

improved via-in-pad technology. Many designers are searching for

solutions to these complex issues. This article covers some key

guidelines for properly performing via-in-pad design.

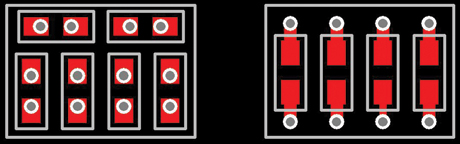

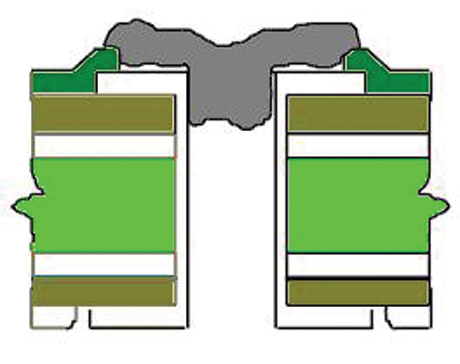

Via-in-Pads and BGAs

Via-in-pad

helps to reduce inductance, increase density and employ finer-pitch

array packages. The via-in-pad approach places a via directly under the

device’s contact pads. This allows higher component density and

improved routing. Consequently, via-in-pad provides the designer

significant PCB space savings. For example, traditional fan-out places

four components, whereas with via-in-pad, six components can be placed

within the same board outline (FIGURE 1).

|

FIGURE 1.

Via-in-pad provides designers significant PCB space savings. In this

figure, traditional fan-out places four components, whereas with

via-in-pad, six components can be placed within the same board outline.

|

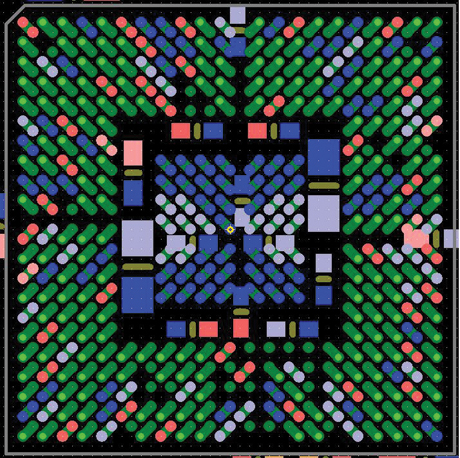

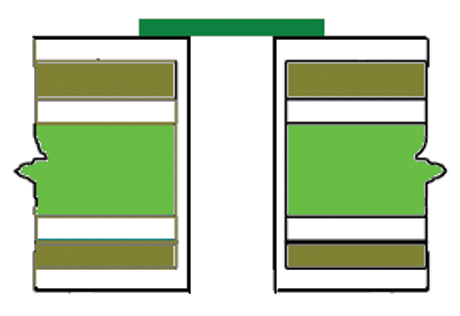

To

illustrate the routing advantages of via-in-pad design, consider the

traditional PCB approach of connecting a via to a pad with a dog-bone

pattern as shown in FIGURE 2.

|

FIGURE 2. The traditional PCB approach of connecting a via to a pad with a dog-bone pattern.

|

When

BGAs incorporate via-in-pad, the need for dog-bones between via pads

and the BGA land is removed. In addition, passive components can be

placed directly over the vias on the bottom side of the BGA, reducing

inductance, rather than outside the perimeter of the BGA (FIGURE 3). A small increase in density is realized by being able to route a few signals out on the surface as well.

|

FIGURE 3.

Passive components can be directly placed over the via on the bottom

side of a BGA, reducing inductance rather than outside the BGA’s

perimeter.

|

Solder Void Formation

With

those design benefits aside, via-in-pad can, unfortunately, be the

reason for solder void formation. That’s the reason surface-mount

design engineers do not like to see via-in-pad designs because it

impacts reliability and yield. With the via hole located in the center

of the pad, there is a probable increase in voiding. Voiding decreases

as the via hole is moved further away from the center of the pad. Via

hole size has a dramatic affect on void formation. The smaller the via

size, the lower the chance of void formation. Also via hole layer depth

proves to have a large impact on void formation. The deeper the hole

(via between extreme layers), then there is a greater chance of a more

solid void.

Via-in-pad causes issues at assembly and

subsequent adverse effects on PCB assembly reliability. Placing

standard through vias (no solder mask coverage) in a solderable pad

leads to solder loss down a via resulting in a starved solder joint. If

the through vias are capped or flooded with solder mask, then air will

be trapped inside the via with solder mask on one side and solder paste

on the other.

During IR (infrared) reflow, the air

will expand and blow the solder mask off the other side. Via-in-pad can

make false opens during ICT (in-circuit testing) if the top of the via

is in a solderable land and the bottom in a test pad; the lost solder

creates a bump and results in a false open. Either option creates

challenges in assembly, as will using deep blinds in solderable lands.

Using via fill with via-in-pad designs results in no entrapped air

during assembly.

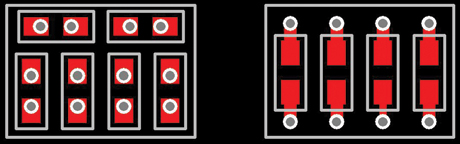

Filled: Via-in-Pad

Via-in-pad with a conductive or non-conductive fill material is normally referred as via fill (FIGURE 4).

Vias are drilled and copper plated, then filled with a polymer

consisting of a blend of copper and epoxy for a non-conductive option

or copper, silver, and epoxy for a conductive option. Once vias are

filled, cured and planarized, the remaining plated holes are processed.

|

FIGURE 4. Via-in-pad with a conductive or non-conductive fill material is referred to as via fill.

|

This

yields a flat copper plated cap over the vias, which facilitates

component attachment. The reason is to completely fill the via with a

material with essentially no voids so that the surfaces are nearly

flat. This material is usually plated over with copper during the

through-hole plating process for the non-filled holes. If the desire is

to have the vias filled to prevent solder drain, then the filling

method needs to be defined. In most applications, the non-conductive

material will meet the needs of the application and is less expensive

than the materials filled with silver or gold.

Methods for Via Fill

It

is important for the PCB designer to have clear communication with the

board fabricator about via-fill requirements. Otherwise, ambiguities

and misunderstandings arise. The following are the common materials

used for solder mask, via plugging or capping, and via filling.

Primary

solder mask is the first application of liquid photo imageable (LPI)

solder mask applied by flood, roller or curtain coat to the PCB. It is

later photoprinted (exposed), developed and cured. It usually covers

the entire board surface except for holes, lands and grounding rails.

Solder

mask applied on specific PCB areas, usually to cover open vias, is

referred to as secondary solder mask. This second application of solder

mask is usually completed using an imaged screen mesh. It is more solid

than LPI solder mask. However, it is still expected to shrink during

the curing process.

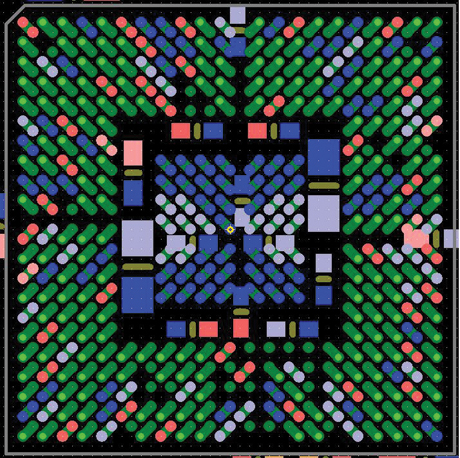

The most commonly used term on

fabrication drawings is via plugging. It is used when the vias need to

be partially or fully filled with some type of material (FIGURE 5). The term via plugging has been used by various designers and covers all of the plugging/filling methods.

|

FIGURE 5. Via plugging is used when vias need to be partially or fully filled with some type of material.

|

Solder

mask encroachment is the least expensive alternative, as it only

affects the primary solder mask artwork. No secondary solder mask or

other filling material is required. Solder mask encroachment is when

the primary solder mask has an opening for a via that is larger than

the finished hole size and yet smaller than the via pad diameter. This

is commonly used to reduce the amount of solder shorts during assembly.

There are many designs where solder mask encroachment without via

plugging is sufficient for high yields during assembly. The rule of

thumb for this approach is if you encroach your vias, you should

measure from pin to encroachment area. The formula used here is for a

minimum 3-mil encroachment:

Pad size diameter –

Solder mask opening diamter of greater than or equal to 6 mils,

provided the solder mask opening diameter is not < the drill size

(nominal hole size + 3 mils).

For example: 16 mil pad - 9 mil solder mask opening = 7 mil, i.e. greater than 6 mils.

This should give you enough pin to via/encroachment (copper to copper) clearance for your assembler.

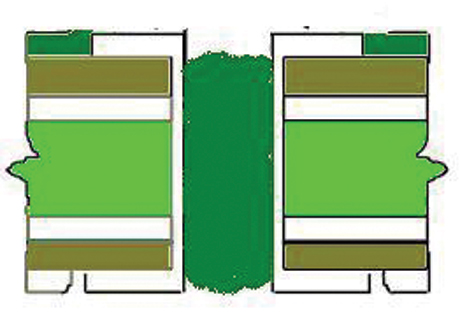

Via

cap is a secondary solder mask application that covers vias and via

pads on the top or bottom sides of the board (not both) after the

conductor surface finish is applied (FIGURE 6). It

only puts a small amount of solder mask in the barrel of the hole. It

is intended to cover the via pad, and most of the vias will have solder

mask spanning the opening of the hole.

|

FIGURE 6.

Via cap is a secondary solder mask application that covers vias and via

pads on top or bottom sides of the board (not both) after the conductor

surface finish is applied.

|

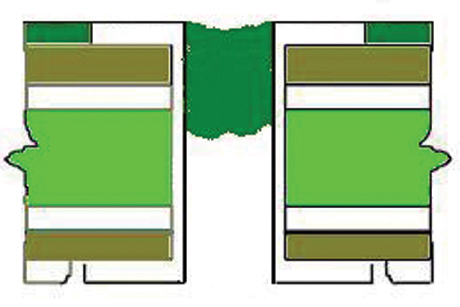

Flooded or tented vias provide no aperture in the primary solder mask for the vias on the top and/or bottom side of the board (FIGURE 7).

The vias are neither capped nor encroached during primary solder mask

application. Since the LPI solder mask has a relatively low percentage

of solids, it will shrink and crack during the cure process, providing

a location to entrap chemistry and fluxes. However, this process has

reliability and assembly issues for most applications.

|

FIGURE 7.

Flooded or tented vias don’t provide an aperture in the primary solder

mask for vias on the top and/or bottom side of the board.

|

Conclusion

Filled

via-in-pad is a way to achieve intermediate density with an

intermediate cost compared to using blind/buried vias. To summarize,

the advantages associated with using the via-in-pad technology are:

- Fan-out, fine-pitch (less than 0.75 mm) BGAs

- Meets closely packed placement requirements

- Better thermal management

- Overcomes high-speed design issues and constraints, i.e. low inductance

- No via plugging is required at component locations

- Provides a flat, coplanar surface for component attachment.

However,

there are some disadvantages associated with this technology. The most

prominent and worrisome is the cost impact associated with adopting a

new technology. PCB fabricators identified two primary cost drivers

associated with specifying via-in-pad technology: additional

manufacturing process complexity and the underlying material cost for

the conductive fill.

Specifically, via-in-pad

technology adds eight to 10 steps to the board manufacturing process,

while via fill cost is a function of the via size and the actual number

of via instances on any given design. However, the reduction in layer

count realized by using via-in-pad technology compensates for the added

cost associated with this process. PCD&F

Ishtiaq Safdar and Faisal Ahmed are PCB layout engineers with NexLogic Technologies, San Jose, CA. They can be reached at This email address is being protected from spambots. You need JavaScript enabled to view it..

REFERENCES

1. Lackwerke, Peters, Technical Information: “Plugging Processes…,” Merix Application Notes.