Vertical in-line plating systems are well-suited for high-volume PCB manufacturing that requires copper plated microvia fill.

Miniaturization and portability of consumer electronics is driving the ever-increasing circuit density of today’s PCB designs. Thin core material, combined with build-up constructions, reduced line widths, smaller diameter through-holes and blind microvias are the key attributes of high density interconnect (HDI) packages.

Electrolytic copper microvia filling is an enabling technology prominently used in today’s manufacture of advanced HDI product. This article describes the features and benefits of vertical in-line (VIL) plating equipment for copper microvia fill mass production.

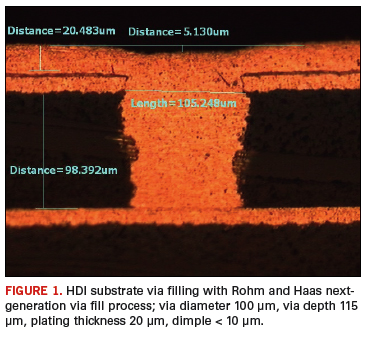

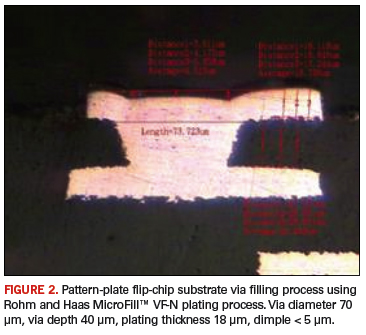

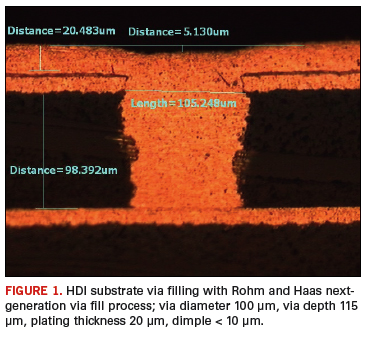

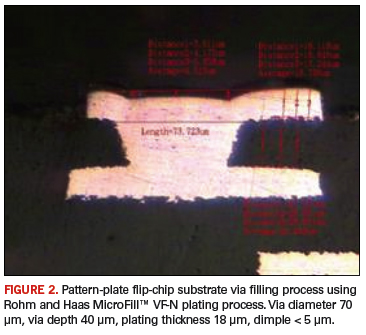

Advanced HDI product designs require planar surfaces after via fill to allow reliable formation of subsequent layers with a minimum amount of copper deposited onto the surface to improve fine-line yield. Via fill quality is typically characterized by a parameter termed “dimple depth,” which represents the difference in heights between the plated copper within a via and around the perimeter of that via. Customer specifications continue to demand increased via fill quality at progressively lower plated copper thicknesses. The capabilities of some current microvia filling processes are illustrated in Figures 1 and 2.

Selection of Electroplating Equipment for Copper Microvia Filling

The following factors should be considered when comparing the advantages and disadvantages of different types of copper electroplating processes for via filling:

- Plating uniformity

- Thin core material handling

- Throughput

- Equipment cost, complexity and footprint.

Copper electroplating process equipment can be generally placed in two broad categories: vertical batch or continuous conveyorized processes. In conventional vertical batch electroplating systems, a number of panels are mounted on a single flight bar and processed in a single vertical plating cell for the full duration of the plating cycle. In conveyorized electroplating systems, the panels are dynamically transported through a series of plating cells.

Continuous conveyorized processes can be further divided into horizontal and vertical systems. While both individual panels and continuous web flex circuits may be processed in such types of conveyorized equipment, this article will focus on processing individual HDI substrates, rather than the use of specialized reel-to-reel equipment for flexible circuit manufacture.

Vertical Batch vs. Conveyorized Equipment

With conventional vertical batch electroplating systems, increased production throughput may be realized by increasing the number and/or the size of the plating cells. When the size of a plating cell is increased, the number of panels within the cell increases proportionally. Depending on the specific design and dimensions of the plating cell, panels may be placed in either single or multiple rows on a flight bar. Unfortunately, this increased panel loading leads to decreased plating uniformity, particularly when comparing panels from the center of the flight bar with those from the ends.

In contrast, the use of either horizontal or vertical conveyorized equipment promotes increased consistency, as each panel “sees” the same overall flow and current distribution as it passes through the equipment. The improvements in consistency can be seen in both better surface thickness distribution and enhanced uniformity of throwing power and via filling, both within a panel and from panel-to-panel.

However, when side-to-side variation within a panel is considered, vertical continuous systems hold a significant advantage in that only vertical systems allow the two sides of the panel to be processed in equivalent physical environments. VIL equipment designs are particularly suitable for via filling applications since the vertical panel orientation minimizes air entrapment and associated skipped or partially filled vias. In contrast, these defects can be problematic on the bottom-side of panels processed in horizontal equipment.

Conveyorized systems have an overwhelming advantage over conventional vertical batch systems when it comes to handling thin-core material. For ultra-thin material, horizontal systems may hold a slight handling advantage over VIL plating systems.

When system cost and footprint are considered, VIL equipment affords considerable advantages versus horizontal designs of similar capacity. Additionally, more advanced multiple track VIL equipment designs are being offered, which provide both conventional conformal plating and via filling capability in a single process line.

A wide variety of system design features that further enhance via filling performance may be incorporated in VIL plating equipment. These include the use of insoluble anodes and engineered fluid delivery devices such as eductors or nozzles designed to create impinging flow on panel surfaces. Insoluble anodes improve plating uniformity by presenting a more stable anode profile over time than copper anodes. Coupled with increased solution flow, insoluble anodes also allow the use of higher operating current densities.

Considering all the different factors that influence process selection for copper via filling, vertical in-line plating equipment offers a very attractive combination of excellent process capability with attractive equipment cost.

There are a number of commercially available vertical in-line plating systems. Figures 3 and 4 show systems that are commercially available from Process Automation International Ltd (PAL) Hong Kong and Applied Equipment Ltd. Taiwan.

Factors Affecting Microvia Filling

The key process factors affecting via filling performance, other than process chemistry formulation and bath composition, are solution flow, current density and pretreatment process.

While lower levels of solution flow will generally improve via filling performance, particularly of large (100 μm or above) vias, this improvement comes at the price of increased risk of improperly filled small (75 μm or less) diameter vias. Improper fill may manifest itself as defects ranging from seams within the plated deposit to completely voided vias. The consequence of this behavior is that equipment parameters must be optimized to achieve acceptable levels of fill and plating quality for the specific applications being run.

The effects of current density are somewhat less complex, as lower current density will both enhance via filling performance and also produce product with lower levels of improperly filled vias. However, the impact of current density is strongest at the very early stages of via filling. Once vias have partially filled, higher current densities can be applied without adverse effects.

While the simplest way to operate a plating process might be to run a single set of flow and current density parameters, use of a more complex operating scheme, incorporating variable flow and current density at different times in the plating cycle, can yield better via filling quality at higher overall production throughput. Although such complex plating cycles can, in principle, be applied to vertical batch processes, their implementation in VIL equipment is much easier. The flow and current density settings in individual modules can be set at different levels to create the desired profile of these two parameters with plating time. Specifically, flow would be greatest and current density the lowest in the initial modules, switching toward lower flows and higher current densities in later modules. The detailed parameter setting will vary depending on a number of considerations, including via dimensions, board layout, customer requirements and equipment capabilities.

Proper control of pretreatment processes also plays an important role in achieving good via filling yield. A typical process sequence uses acid cleaner, micro-etching and acid dip steps to make sure the copper substrate is clean (free of contamination and surface oxidation) and properly prepared for the subsequent copper plating step.

Summary

Vertical in-line plating systems offer an attractive alternative for high-volume PCB manufacturing with features particularly suited to copper microvia filling. In conjunction with more capable equipment, copper via filling electrolytes are also evolving to provide more capable and consistent performance. This combination of VIL equipment and chemistry offers end-users a cost-effective, highly capable and production-proven process for HDI substrate microvia filling. PCD&F

Bruce Chen is assistant engineering manager RD&E – Rohm and Haas Electronic Materials Taiwan Ltd. He may be contacted by email at: This email address is being protected from spambots. You need JavaScript enabled to view it..