New glass fabrics promise to resolve challenges in high tech PCB design and fabrication.

Among the many challenges facing the electronics industry today are

those related to the need for increased speed. These challenges include

improved signal integrity and increased product reliability at

multi-GHz clock rates with inherently smaller threshold voltages and

picosecond rise/fall times. The implication of increased speed

continuously challenges the industry.

In recent

years, numerous technical papers have proposed methods to deal with

these challenges, coining the phrase “fiber weave effect” or FWE to

describe one of the central issues associated with the influence of the

glass reinforcement fiber on the electrical performance of the PCB1-7.

While many solutions have been presented to deal with FWE, none have

addressed the actual woven glass fabric in the laminate material. The

questions posed are these: Can an innovative glass fabric technology

improve end product performance? Can a raw material so far back in the

supply chain have an impact on leading edge industry challenges?

The

answer to both questions is Yes. A new high performance glass fabric

technology has been developed that demonstrates uniformity of glass

weave resulting in a homogeneous reinforcement layer. Used with readily

available resin technologies, this new glass fabric can provide

improved physical properties (laser and mechanical drilling,

dimensional stability and surface smoothness), superior electrical

properties (CAF resistance), and enhanced performance properties (more

uniform Dk and circuit impedance, reduced signal skew, and improved

signal integrity).

Many solutions have been

proposed to address FWE in circuit boards, however, in all of these

approaches there has been an implicit assumption that the glass fabric

reinforcement layer itself cannot be improved upon. This assumption is

not true. Consider a Style 1080 fabric, perhaps the most commonly used

glass fabric in high performance multilayer PCBs. The standard

construction of this style involves 60 yarns per inch in the warp or

machine direction and 47 yarns per inch in the weft or cross-machine

direction. The 1080 designation also specifies the type of yarn, as per

IPC-4412A9.

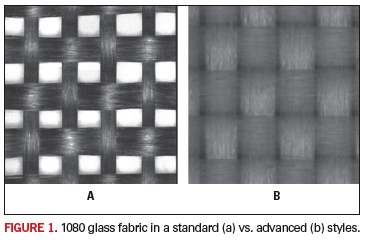

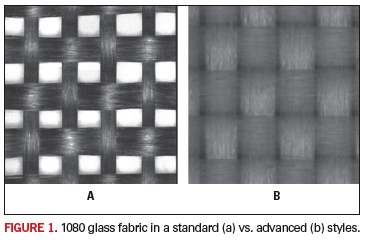

Figure 1

shows standard 1080 (a) and the high performance 1080 (b). Both have

been made according to the IPC specification. Each has exactly the same

quantity of glass with the same number of warp and weft yarns. The most

obvious physical difference between these fabrics is the spread out

ribbon-like yarns in the right-hand photo. To determine the properties

of these fabrics, we must first understand the underlying technologies.

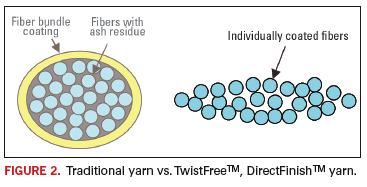

In

the manufacture of traditional fiberglass, the yarns are coated with a

vegetable-based starch-oil mixture to facilitate weaving. This coating

is then removed in a lengthy heat clean step, after which the yarn

bundle receives a silane coating. Depending on the tightness of the

weave and/or any ash residue left from the heat cleaning, the

individual yarns may or may not be fully wetted by the resin matrix. In

addition, the heat-cleaning step reduces the glass fabric strength by

approximately one third. Therefore, elimination of this damaging step

will create a stronger, more dimensionally stable composite.

Direct

application of a final resin-compatible finish during the fiber-forming

process provides a better interface between the glass fiber

reinforcement and the resin matrix8. This resin-compatible

finish is applied to the pristine surface of individual glass fibers

immediately as they are formed, remaining on the yarn and glass cloth

throughout the manufacturing process.

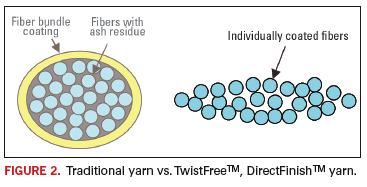

Another significant difference is seen in Figure 2,

where the contrasts between a twisted fiber bundle and the more

advanced untwisted yarn are highlighted. Traditionally, the glass fiber

bundle is twisted to give strength and mechanical integrity to the yarn

and make it easier to weave into fabric. Twisted yarns are somewhat

rope-like, making thicker cross-points in the glass fabric (often

referred to as knuckles). Twisted glass fiber is also known to

contribute to stresses within the laminate.

Untwisted

yarn is more ribbon-like, lies flatter and spreads out easily. This

yarn construction yields a more consistent fabric, where glass fibers

are more uniformly distributed, and weave knuckles and open areas are

minimized.

Refer again to Figure 1, which shows two

different fabrics with the same amount of glass, but with the glass

fibers distributed differently. The traditional glass reinforcement

(Figure 1a) is thicker and unevenly distributed, leading to

inconsistent substrate properties. There are essentially three

differing glass thicknesses in the fabric: areas with two layers of

yarns (at the knuckles), areas with just one layer, and the interstices

between the yarns where there is no glass. In Figure 1a these areas are

very distinct from each other, while in Figure 1b the fibers have been

spread out to fill the interstices.

Figure 3

further illustrates this concept. For the best mechanical, electrical

and performance properties, total glass uniformity is key. This is a

direct result of maximizing the amount of two-layer coverage. In Figure

3 we have quantified the amount of zero, one and two-layer coverage

using red, yellow and green areas (respectively) overlayed onto the

photos from Figure 1. The percentages shown are based on measurements

from the photographic images.

Considering that these

two fabrics contain the same amount of glass, it can be presumed that

the fabric in Figure 1b is thinner than 1a, and this is indeed the case

as confirmed by measuring total fabric thickness9. In fact,

the two-layer areas of glass in the traditional fabric are

approximately 50% thicker than the two-layer areas in the advanced

glass on the right (2.1 mils vs. 1.4 mils).

In

addition to a more uniform glass configuration, this new glass fabric

utilizes a lower dielectric constant (Dk) glass composition to reduce

the Dk difference between glass and resin. This Dk difference is at the

root cause of FWE. In traditional 1080 fabric using E-glass, the Dk

difference between the glass and high performance resin is

approximately 4 units. With the new fabric this Dk difference is

reduced by half. When the lower Dk is combined with smoother fabric,

the FWE can be significantly reduced.

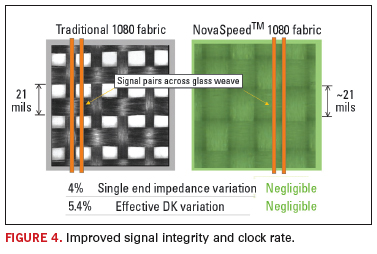

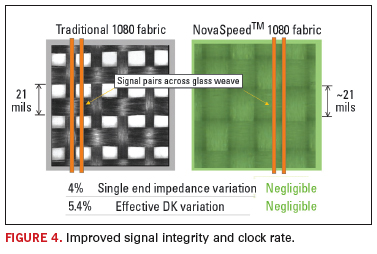

In Figure 4,

the photos from Figure 1 have been overlayed with 3-mil lines to

approximate scale for illustration purposes. Both fabrics have the same

amount of glass but it is distributed differently. Estimates of single

end impedance and effective Dk variation for traditional 1080 fabric

are based on data presented in a paper by Brist et al at IPC Expo 20042.

Among

the many proposed solutions to address FWE is the use of a heavier

fabric style that has a balanced construction and tighter weave that

can reduce the open spaces7. However, addressing the issue

by glass style alone does not improve upon the other important aspects

discussed above. Indeed, laminate core thickness below about 4 mils

cannot be achieved using these heavier fabric styles.

Test Results

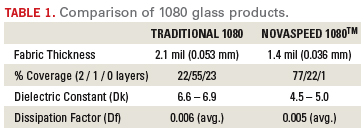

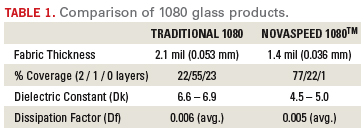

Table 1

shows initial test data on glass fabrics. The thickness measurements

are per ASTM D579 (25 psi). Dielectric constant (Dk) and dissipation

factor (Df) for the NovaSpeed 1080 fabric was measured at 10 GHz using

the NIST split cavity method at the Materials Research Lab at

Pennsylvania State University10. These measurements were

subsequently corroborated by calculations from test laminates per

IPC-TM-2.5.5.5 (stripline method). The traditional 1080 Dk and Df

measurements were taken from a table compiled by the IPC 3-12d Glass

Reinforcement Task Group and represent data from four global

manufacturers of E-glass yarn11.

As

previously described, the Dk of the NovaSpeed glass fabric is lower

than that of E-glass in traditional fabric. More precisely, the Dk of

this fabric is midway between that of E-glass and typical high

performance resin systems. Thus the Dk difference between glass and

resin is half of that seen in typical laminate products.

Table 2

shows Dk and Df results at 10 GHz with the low Dk 1080 glass fabric

alone, and with three commercially available resin systems. These resin

systems, while high performance, are not characterized as “exotic” but

are considered to be “FR-4 processable.” The bulk glass measurements

were done using the NIST split cavity method and all other measurements

are per IPC-TM-650 2.5.5.5 stripline method.

Conclusion

Based

on the known characteristics of this advanced glass fabric, direct

improvements can be predicted. The flat, smooth laser-drillable glass

fabric will have improved laminate surface planarity and inherently

lower surface roughness, as compared to laminate made with traditional

glass fabrics. Improvements in “telegraphing,” laser-drilled hole

geometry, hole plating quality and laser drilling speed can be

expected. Where mechanical drills are used, a reduction in drill wander

can also be expected. Furthermore, the high strength properties of a

directly finished fabric, combined with the more uniform distribution

of the glass fiber yarns, provides improved dimensional stability in

circuit board laminate applications.

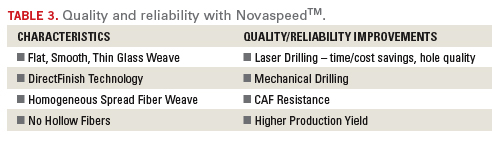

The use of a

direct finishing technology combined with the spread fibers of

untwisted yarn results in greatly improved wettability and resin

impregnation (of the glass bundles), and therefore the highest quality

glass-to-resin bond is ensured. This property is the main factor in

improved CAF resistance. An electrochemical migration phenomenon

similar to CAF is caused by hollow fibers. This low Dk glass fabric

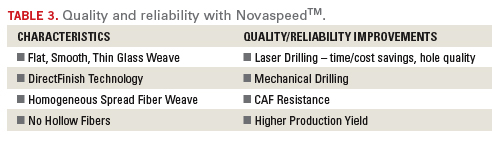

exhibits zero hollow fibers. Table 3 summarizes these characteristics with corresponding quality and reliability improvements.

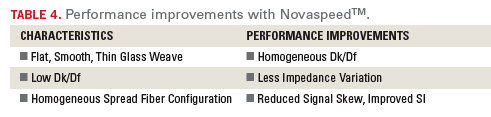

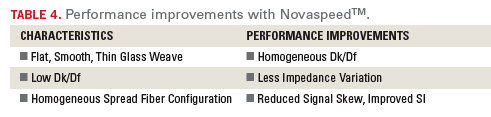

Table 4

identifies performance improvements that result in the fabric with the

combination of an improved finishing method, a non-twist glass, and a

proprietary low Dk glass formulation. The printed circuit substrate

exhibits a homogeneous Dk and Df, leading directly to less impedance

variation and reduced signal skew, resulting in improved signal

integrity.

An advanced glass fabric has been utilized

in several high performance commercial resin systems to generate test

panels with superior electrical properties at 10 GHz. However, by using

a unique manufacturing process and proprietary low Dk glass

formulation, a homogeneous reinforcement layer has been developed that

is unlike traditional glass fabrics. In fact, the key features of this

proprietary technology are not addressed by existing industry

specifications.

It is expected that FWE can be

completely eliminated as a performance constraint in high speed PCB

susbstrates with the use of this novel technology. This new glass

fabric could represent a paradigm shift for PCB substrate performance. PCD&F

Russell S. Dudek Jr. is a technology specialist at Compunetics; This email address is being protected from spambots. You need JavaScript enabled to view it.. John J. Kuhn is VP and CTO and Patricia Goldman is manager, technical services, at Dielectric Solutions; This email address is being protected from spambots. You need JavaScript enabled to view it., This email address is being protected from spambots. You need JavaScript enabled to view it..

REFERENCES

1. K. Dietz, “Fine Lines in High Yield (Part XCVIII): Advances in Reinforcement Structures,” TechTalk in CircuiTree, November 2003.

2. G. Brist, B. Horine, G. Long; “High Speed Interconnects: The Impact

of Spatial Electrical Properties of PCB due to Woven Glass

Reinforcement Patterns,” S18-5-1, IPC Expo/SMEMA Council/APEX/Designers

Summit 2004.

3. E. Bogatin, S. Zimmer, “Achieving Impedance Control Targets,” Printed Circuit Design & Manufacture, April 2004.

4. S. McMorrow, C. Heard, “The Impact of PCB Laminate Weave on the

Electrical Performance of Differential Signaling at Multi-Gigabit Data

Rates,” DesignCon East 2005.

5. E. Bogatin, “Skewering Skew,” Printed Circuit Design & Manufacture, April 2005.

6. J. Loyer, R. Kunze, X. Ye, “Fiber Weave Effect: Practical Impact Analysis and Mitigation Strategies,” CircuiTree, March 2007.

7. L. Ritchey, “Intelligent Design,” CircuiTree, April 2007.

8. J. Kuhn, “Advanced Reinforcement Technology Presents New Design

Opportunities for Printed Circuit Boards”, ECWC 10 Conference at IPC

Printed Circuits Expo/APEX/Designers Summit 2005.

9. IPC-4412A, “Specification for Finished Fabric Woven from “E” Glass

for Printed Boards,” January 2006, IPC, Bannockburn IL..

10. NIST Split Cavity method for measurement of relative permittivity

[Dk] and loss tangent [Df], subsequently standardized as IPC-TM-650

2.5.5.13.

11. Committee Report of Woven Glass Reinforcement Task Group 3-12d from

IPC Apex/Expo 2007 (ipc.org/CommitteeDetail.aspx?Committee=3-12D).