BANNOCKBURN, IL – The establishment of a pilot facility in the US for manufacturing IC substrates is a first step towards re-establishing semiconductor packaging within the United States, and the CHIPS and Science Act of 2022 can be used to jump start the effort, according to a white paper released by the IPC's Chief Technologist Council.

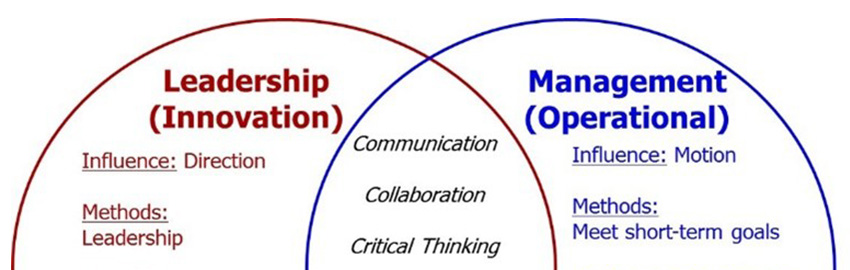

After decades of offshoring for the PCB and IC substrate industry, the experience base in implementing and executing the operational management of an IC substrate fabrication facility is nearly non-existent in North America – for both the leadership skills required as well as the process engineering expertise which provides the backbone of these operations, the paper states. There is also no real “surplus” of PCB manufacturing expertise available to seed an IC substrate fabrication facility, and this is amplified by the fact that PCB companies are generally risk averse.

While the CHIPS Act is meant to jump start the effort, the competition for funding has led to the proposed creation of complicated, highly centralized mechanisms that are likely to eat up funding while failing to address the underlying needs.

The CTC's recommendation for the funding is to build an IC substrate fabrication pilot line, which neither has to be, nor should be, state-of-the-art as its initial technology point. Rather, it should be set up to allow for capabilities to grow quickly, targeting state-of-the-art in the future without being held hostage to these eventual requirements in the short term. The committee also recommends that this facility be implemented as a US asset, following a consortia model like the High Density Packaging User Group, allowing any company to join, participate, contribute and realize the benefits of the effort.

The CTC says the facility should not be “squeezed” into a surplus building that is donated, but should instead be constructed with the end in mind. Plan for the next iteration/generation of equipment, acknowledging that more is required, and that more is both possible and required. The expansion space must be available at time zero, so that as version 1 is implemented, version 2 already being planned and has available space. When version 2 is implemented, version 3 is planned for the space that the newly obsolete version 1 currently occupies. The model would be to continue to swap out the equipment, incrementing capability at a sustainable pace.

This facility would not only start to resolve the IC substrate manufacturing shortfall, but would also be geographically located to facilitate the other weaknesses that have been identified in the semiconductor packaging ecosystem, the paper says, and there should be a university presence nearby with an outstanding and recognized electronics curriculum, ideally staffed with highly experienced industry subject matter and operations experts. The curriculum can utilize this pilot facility as a sort of “Unit Ops Lab” specific to PCB or IC substrate fabrication.

Additionally, it should have easy access to semiconductor and outsourced semiconductor assembly and test (OSAT) facilities. After all, this is an ecosystem we are trying to build, and other facets of this ecosystem need to be taken into account. An example of this type of model is the Center for Advanced Microelectronics Manufacturing (CAMM) advocated and administered by Binghamton University in New York.

Once geographically and organizationally closer relationships between research, industrialization of technology and manufacturing have been re- established, direct feedback loops between these three disciplines will be enabled, and knowledge rebuilding will be fostered. This should result in reduction of defect costs as well as facilitation of innovation and finally new developments. Such an endeavor initially localized in the US should also spur the attention of other stakeholders in the West, e.g., Europe, which would breathe new life into IC packaging efforts globally.