Making a circuit design robust adds complexity to the design process.

If an analog/mixed-signal (AMS) circuit design is reliable, is it also robust? Conversely, if an AMS circuit design is robust, does that make it reliable? The answers are no and yes.

A reliable circuit design performs its intended function when conditions are nominal, meaning as long as design parameters or environmental conditions remain stable, you can count on a reliable circuit design to do its job time after time. But what happens if these same design parameters or environmental conditions start changing, either slightly or significantly off nominal? The answer is simple: Reliability goes out the door. With the right development approach, however, a circuit design can be both reliable and robust.

Making an AMS circuit design reliable usually involves a fairly straightforward design process; turn the nominal design specifications into a functioning circuit design. Making a circuit design robust, however, adds additional complexities to the design process. First is the need to identify possible variation sources such as those arising from a change in the environment or deviations in a device’s function. Next, it must be determined how these variations affect circuit performance versus the design specifications and goals. And finally, knowing how variations affect performance, the circuit design needs to be improved and optimized. Sound like a lot of extra work? It can be. But if design performance must be robust as well as reliable, the extra work is necessary and worthwhile over the long run.

It used to be commonplace that designing an AMS circuit to achieve a desired behavior meant focusing on meeting the specification or achieving the performance goal for the intended behavior. Anticipated changes in environmental conditions and component variations could be accounted for by over-constraining the design, and performance could be verified by building and debugging prototypes in the lab. This labor- and time-intensive approach, however, is no longer practical, as many circuit designs are often part of larger systems that have their own set of tolerances, loading effects, or electromechanical components whose effects on performance goals must be accounted for in the subsystem circuit design. Also, real-world environmental conditions are not static and often difficult to mimic on a bench or in a lab.

More often than not, today achieving design robustness with shrinking development schedules, and increasing levels of circuit complexity, requires virtual prototyping and comprehensive analyses as part of the design process. Incorporating virtual prototyping and comprehensive analyses into the process means reliability and robustness can be “designed,” rather than “tested,” into a circuit design.

For the virtual prototyping environment to be useful, it must have the right models and the right analyses. Getting the model piece right means choosing options that allow modeling whatever technology and performance details the circuit design requires. If the circuit design is 100% electrical, and voltages and currents are all you’re interested in, Spice is usually an adequate modeling answer, though there are better and more informative ways to tackle Ohm’s law. But the moment your modeling needs extend beyond Ohm’s law, accurate circuit modeling and simulation requires more capability, the capability found, for example, in a multi-physics hardware modeling option like the IEEE standard VHDL-AMS language. With a modeling language like VHDL-AMS, models can be created that accurately predict component and circuit performance beyond standard voltage and current relationships. Consider, for example, the importance of understanding a circuit’s dynamic thermal performance, the influence of a component’s second and third-order effects, or how loading a DC motor might impact the driver circuit’s operation.

Getting the analysis piece right means selecting a simulation toolset that takes advantage of the model library to run the circuit design through its paces, from a straightforward what-if to a comprehensive worst-case performance analysis. Having the basic analyses – standard time and frequency domain options – will get you to the “reliable design” stage, but the “robust design” stage requires looking at circuit performance, as real-world variability in components, environment or operating conditions start changing from their nominal values. When variations start to affect a circuit design, rest assured performance issues are not far behind.

Accurately analyzing variability requires advanced analyses such as:

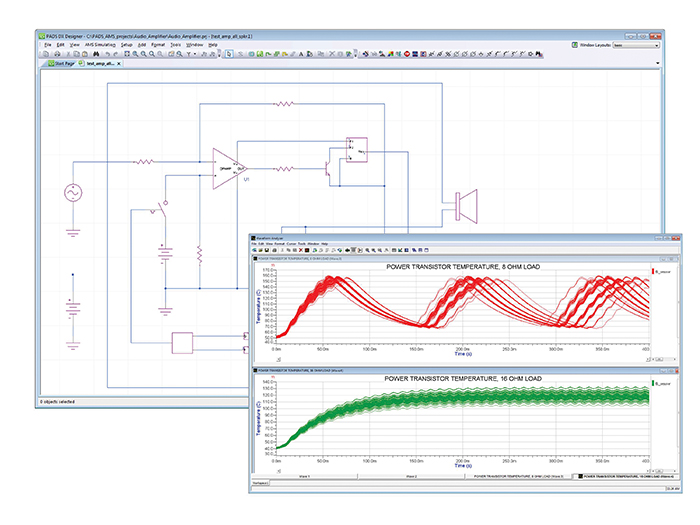

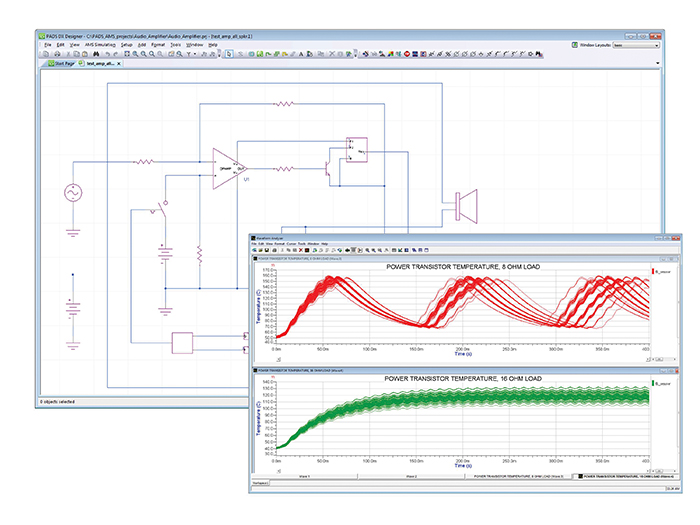

- Parametric sweep. Sweep component and design parameters through user-defined ranges to analyze how specific parameter combinations affect circuit performance (FIGURE 1).

- Relative, tolerance-based, and statistical sensitivity. Determine how sensitive a circuit performance metric is to individual component and design parameters.

- Statistical (Monte Carlo). Examine how component manufacturing variations, including the effects of tolerance stack-up and extreme value parameter combinations, influence circuit behavior.

- Worst case. Predict circuit performance extremes based on selected combinations of component parameter limits.

Figure 1. Parametric sweep analyses can turn up some surprising circuit behavior. Here, changing from an 8Ω speaker to a 16Ω speaker has a marked effect on the temperature of the power amplifier.

Better modeling practices and extended/advanced analyses can contribute to more reliable and robust analog/mixed-signal circuit designs. Sometimes the required process change is small; sometimes it is substantial, almost like an entire design paradigm shift. But the reward, whether measured in improved product reliability or robustness, is often worth the investment.

Josh Moore is product marketing manager at Mentor Graphics (mentor.com); This email address is being protected from spambots. You need JavaScript enabled to view it..

Register now for PCB West, the Silicon Valley's largest trade show for the printed circuit industry, taking place Sept. 13-15 in Santa Clara: PCBWEST.COM