Understanding the critical process steps in design, fabrication and

assembly can increase the robustness of the PTH and improve reliability.

PCB real estate, along with components, vias, and annular ring sizes

are shrinking dramatically. Five or 10 years ago, a via hole of 15 to

20 mils with a 5 to 10 mil annular ring was the norm. Now, via sizes

ranging from 7 mils down to 4 mils on highly complex boards are

increasingly more common. As through-hole size (via) shrinks, so does

the annular ring, posing major challenges to fabrication and assembly

manufacturers in the process.

In earlier PCB

generations, two to three mils of play (or wander) within a 10 mil hole

was common. Currently, precision laser drilling allows about 0.5 mil

wander, (sometimes less) as smaller drills have reduced via size to 4

or 5 mils. To illustrate, this means that one mil of wander represents

25% of the hole size when a four mil via is created.

Consequently,

tighter fabrication and assembly controls and tolerances,

state-of-the-art equipment and trained technicians must be utilized at

design, fabrication and assembly to assure high plated through-hole

(PTH) reliability. Laser drilling equipment must be up-to-date, highly

precise and accurate to ensure that vias and annular rings remain

intact as a PCB undergoes the multiple heat and reflow cycles during

the different phases of fabrication and assembly.

Sufficient

clearance is necessary to avoid creating break out on internal layers.

This condition is typically caused by miscalculations of drill size,

pad size, incorrect annular ring size or over-etching at fabrication,

resulting in weak or broken continuity.

Lead-free

design, fabrication, and assembly are especially vulnerable areas

requiring careful attention to assure PTH reliability. Experienced EMS

providers fully understand that proper focus must be placed on

selecting the correct PCB material, ensuring proper thermal profile

characteristics, and choosing the right flux as part of assembly

precautions in order to insure long term PTH reliability.

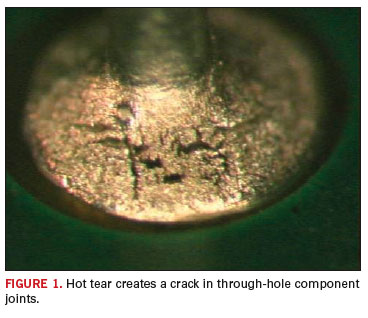

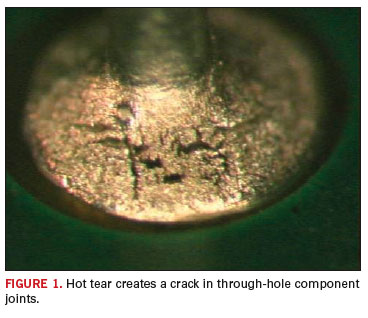

Currently,

the lead-free assembly industry is experiencing an anomaly called “hot

tear,” which occurs with the use of SAC305 lead-free solder. As shown

in Figure 1, hot tear is a crack created in a through-hole component joint. SAC305 manufacturers are now investigating this problem.

With

lead-free projects, PTH reliability is also dependent upon the right

choice of flux at PCB assembly levels. Contract manufacturers (CMs) are

now dealing with a very narrow window of flux activity at a

considerably higher temperature levels. At these higher temperatures,

error tolerances are greatly reduced. Without the correct solder and

flux composition and proper thermal profile, PTH reliability is

severely jeopardized.

At Design

A

major function in DfM of the PCB is to determine accurate calculations

for through-holes and plated slots. These calculations apply to

determining via diameter in relation to annular ring size; another is

setting correct via spacing and consistently maintaining that spacing

for good signal integrity.

Accurately calculating

drill hole and annular ring sizes is critical. A larger hole diameter

requires a larger annular ring. Miscalculation in annular ring design

creates long-term reliability issues, especially at rework levels.

Experienced and disciplined designers refer to IPC610D and IPC221A

charts to obtain PTH and annular ring definitions as a basis for making

precise calculations.

The designer must also

carefully select the proper type of copper foil when designing a PCB.

Choices for copper foil are typically one-half, one, or two ounces.

When one-ounce copper foil is used, each square inch of the board will

be layered with one ounce of copper. However, in an analog PCB

application designed for higher current, a two ounce copper foil may be

required to insure the capacity for proper current flow. The choice of

the correct internal copper foil is an important consideration in PCB

long-term, reliability.

The copper deposited on the

hole wall through the plating process is also critical in the PTH

reliability equation. If insufficient copper is deposited on the via

wall long-term reliability can be affected. The problems created by

thin copper can include fractures or cracks in the barrel of the via,

leading to poor solder joints and intermittent or broken continuity in

the current flow. Recently the IPC reduced it’s the PTH thickness

requirement to a minimum of 0.8 mils. In some cases this may not be

sufficient copper for a particular design. If designers require more

copper in the PTH they will need to specify it on the drawing or the

fabricator can use the IPC guideline.

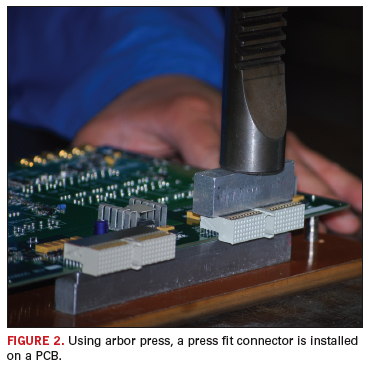

Connectors

and sockets require special design attention. Performing the right PTH

calculations are particularly critical because connectors and sockets

demand greater PTH precision, especially for press fit connectors. If

drill sizes and annular rings are calculated poorly, there is the

possibility of creating a through-hole that is too small to accept the

connector. And while it may be possible to maneuver a component lead

into a too-small plated-through hole, such actions often increase the

probability of cracked vias in the middle of the wall, creating an

unreliable connection. This problem can either immediately surface

during test, or become a latent or intermittent defect, causing

reliability issues for products in the field.

Reliability

becomes a major issue when via-in-pad technology is used. In some

manufacturing schemes, via-in-pad uses different materials and

processes than are used in conventional through-hole via. In some

cases, a conductive material such as epoxy or silver is used to fill

the via. For via-in-pad, a PCB fabricator must fully understand how

these materials will differ from the conventional via creation to

maintain the board within its own specific tolerances. This is a

challenge because the technology is still new, there are few

fabricators that have the necessary trained staff, experience, and

equipment to provide the high level of PTH reliability required today

from this technology type.

Plated through holes

using SMA connectors in high-speed designs require simulation modeling

also known as via modeling. This software assures there are no

reflections or discontinuities along along the electrical signal paths

to assure certain transition points are smooth. This is especially

important when there is a cable or connector used in the board.

Therefore, the optimal design requires that through hole components and

vias are designed with proper transition points, eliminating

reflections, discontinuities, or sudden changes in signal impedance

requirements.

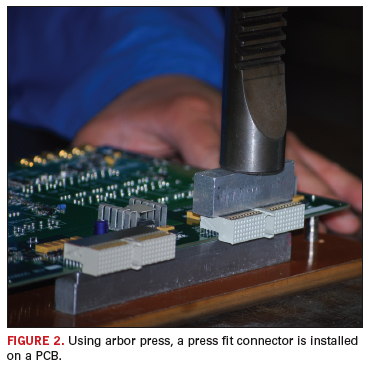

Rework cycles should also be considered

at PTH design. This is especially critical to press fit connector

reliability, as the connector will not tolerate warp or movement of the

board (see Figure 2) and is more prone to defects

during rework cycles. Extremely accurate PTH design is required for

these connectors, as after a mistake in the PTH process is made,

reworking a press-fit connection is extremely difficult. If the via is

too small, the connector won’t insert into the board; if too big, an

intermittent connection is created.

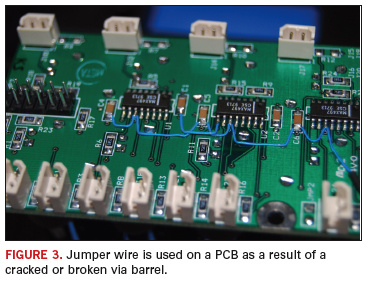

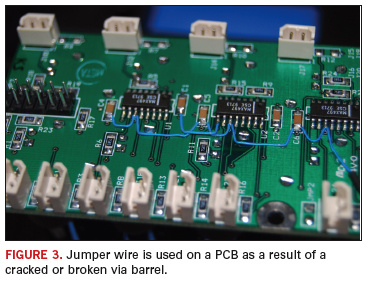

One of the few rework options involves cutting and adding jumpers. As shown in Figure 3,

an incorrect PTH calculation resulted in a too-small PTH. The via broke

off the board, and an unsightly jumper wire is used to recreate the

connection. Besides the aesthetic considerations, this repair method

lacks the level of reliability of a properly designed via.

At Fabrication

When

considering drill and pad sizes, a ± 3 mils tolerance is typical for

vias up to a 10 mil size. Some are tighter, where tolerances could be

+3 and -0 for a 7 mil or smaller sized via. There are specific

guidelines for drill hole and pad sizes. For instance, a 10 mil drilled

hole must have at least a 22 mil annular ring, allowing at least a 6

mil annular ring on each side. When space permits, a larger annual

ring, such as 26 to 30 mil would be preferable, to create a more solid

pad joint able to withstand several component extractions and

placements, as well as being able to undergo multiple reflow cycles

without incurring problems.

Aspect ratio, which

refers to the comparison of board thickness to the smallest via created

on that board, must also be carefully reviewed, as it plays an

important role in PTH reliability. The greater the aspect ratio, the

more difficult it is to fabricate the board and to assure that it’s

plated through holes will maintain reliability throughout the product

life. A 10:1 or 12:1 aspect ratio is standard, but there are now 30:1

ratio PCBs constructed for specialized applications. This 30:1 aspect

ratio board requires more precise pad-to-hole ratio calculations for

PTH reliability. It’s important to maintain robust drill sizes and

annular rings for high aspect-ratio boards to avoid half-moons and

breakouts.

The different board fabrication cycles

need to be followed and precisely implemented. This includes a number

of precise process sequences that must be at specific temperatures for

defined periods of time. There is always the possibility that a quick

turn order will have a few corners cut. The OEM must be sure that the

PCB fabricator doesn’t shorten the bake cycles in order to meet tight

shipment schedules. This can severely compromise long-term product

reliability. Such shortcuts could result in numerous problems, from

insufficient material cure and moisture absorption to incomplete

stabilization of the processing materials.

In

addition, if preventative maintenance is not regularly conducted on the

various chemistries used plate and process the PCBs, they it may become

contaminated or may stop performing as required. This contamination, as

in the case of a contaminated copper electroplating bath, can cause

vias to be more susceptible to cracking during the reflow cycles in the

assembly stage.

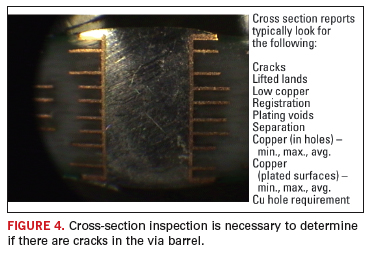

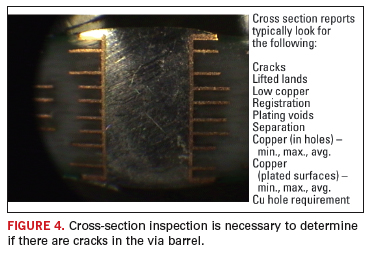

A cross-sectional inspection and

analysis, as well as other relevant testing, are often required to

pinpoint hairline cracks in the via’s barrel (Figure 4).

These defects may not be readily apparent and may pass a non-stressed

electrical test at the PCB fabrication facility and through the final

quality control without notice.

Two

tests are used to further insure PTH reliability. The first is a PTH

Life Curve; the second is a Current Induced Thermal Cycle Test (CITC).

The PTH Life Curve test plots a curve that determines when and how a

PTH fails during accelerated thermal cycling. CITC inspects and tests

the different board materials, finishes, and via construction. Both

tests determine through-hole longevity before they begin to show

fatigue characteristics and other reliability issues that might not

otherwise become apparent until the product is in the field.

At Assembly

Among

the major requirements for maintaining high PTH reliability is a well

organized, trained, disciplined, and comprehensive incoming audit and

inspection for fabricated boards entering the assembly process. The

focus here is on via stability and reliability. Inspectors should

insure that sample vias, annular rings and holes are thoroughly plated

and within tolerances as specified in the fabrication design

documentation. This includes insuring that holes designed to be

non-plated aren’t mistakenly plated through.

The

board is also subjected to different thermal cycles at reflow and wave

solder stages. Reflow incorporates multiple heat zones, gradually

increasing board temperature then holding it at a peak level, then

reducing it, so that the board experiences fatigue as a result of

repetitive temperature cycling. Here, the Z-axis expansion of the via

barrel alloy needs to match the expansion of the board material

composition. Alloy composition is different than the board’s material

composition, and this mismatch creates fatigue that can cause cracks in

the via barrel when subjected to heat cycling.

Temperature

spikes between critical zones within reflow ovens also have the

potential of creating temperature fatigue at PTH and vias. This fatigue

ultimately damages through-hole components when they undergo excessive

wave soldering cycles.

Special attention must also

be given to via size expansion and contraction since the board is

exposed to varying temperature ranges. This is especially important for

micro vias with thin plating on the via barrels. Via expansion and

contraction – which is inevitable in the assembly process – will take

its toll on PTH reliability unless all of the previously outlined

design, fabrication and assembly guidelines are carefully followed.

PCD&F

Zulki Khan is president and founder of Nexlogic Technologies; This email address is being protected from spambots. You need JavaScript enabled to view it.