A DfA program that designs and specifies PCBs compatible with lead-free

soldering is often at odds with a cost driven manufacturing metric.

Significant attention and a great deal of effort have been expended

on understanding the reliability of lead-free solder joints. However,

difficulties posed by lead-free soldering as it relates to the

reliability of PCB interconnect structures is perhaps more significant.

Problems with PCB viability after the assembly process comes primarily

from one source – the temperatures required to attach components during

the lead-free assembly soldering process. These reliability issues

required the development of a White Paper1 from which the materials in this article were taken.

With

SnPb soldering, PCB reliability was typically not an issue, but in our

brave new lead-free world, this is no longer the case. PCBs now need to

be designed and specified to be fully compatible with lead-free

soldering. Unless these changes are included in the specification of a

PCB, this will not happen, because PCB fabricators will build based on

lowest possible cost. To carry out the changes needed to assure

lead-free assembly success often comes with an increase in

manufacturing cost.

PCB Base Materials

To

assure the survival of PCBs during the high soldering temperatures and

their subsequent reliability afterward, improvements in PCB resin

properties are necessary. The integrity of the PCB interconnect

structures – plated through-hole copper barrels and barrel/inner-layer

interconnects – requires improved glass transition temperatures (Tg)

and lower coefficients of thermal expansion (CTE). Improvements in Tg

and decomposition temperature (Td) are also necessary for the thermal

stability of the PCB resin.

PCB base and prepreg materials are frequently specified according to industry document IPC-41012.

It should be noted that using IPC-4101 slash sheets for material

choices is not sufficient to specify specific properties. The range of

properties contained in these slash sheets is too broad for this

purpose. It is therefore recommended that specific materials or their

equivalents be specified for critical applications.

The

glass transition temperature should be determined using the

Thermo-Mechanical Analysis (TMA) method, as per IPC-TM-650, 2.4.24C3. This method is preferred over DSC4 and DMA5,

two other methods used to determine the glass transition temperature,

because thermal expansion of the PCB is a critical parameter and is

given by TMA as a function of temperature.

For all but thin PCBs, a minimum decomposition temperature, Td (determined as per IPC-TM-650, 2.4.24.66)

as well as a maximum thermal expansion coefficient in the PCB thickness

direction, CTE(z) (determined as per IPC-TM-650, 2.4.417)

should be specified. CTE(z) values should be given separately for

temperatures below Tg and above Tg, however, thermal expansion (TE in

%) is often given in a range of temperatures from 50 to 260ËšC; good TE

values typically are 3.2% or less. Typically, the decomposition

temperature is given as Td (5%) to a 5% weight loss. A decomposition

temperature of Td (2%) to a 2% weight loss has been found to be a

better indicator, but data based on this parameter is not yet widely

available.

Often, the time to delamination (T-288 or

T-260) is specified, either in addition to Td, or instead of it. The

T-288 delamination time provides a more appropriate level of

performance, given the process temperature required for lead-free

soldering. Delamination time is sometimes combined with the requirement

that the PCB needs to survive the process temperature for 4 to 5

excursions.

Unfortunately, the data sheets from the

various laminate/prepreg suppliers are typically neither consistent not

complete. Moreover, where property measurements were performed by

commercial laboratories (because the values given in the data sheets

did not appear to be credible) the values of the CTE(x) and CTE(y) were

found to be nearly double those given in the data sheets.

When

qualifying laminate materials, during the preliminary search,

elimination and final selection process, the three properties that

critical for the survival of the PCB and the PTH/via interconnect

structure in a lead-free assembly are:

- Glass transition temperature = Tg

- Decomposition temperature = Td, and

- Thermal expansion = TE

These

critical parameters can be combined in a Soldering Temperature Impact

Index, STII, which is defined as STII = Tg/2 + Td/2 – (TE%(50 to 260ËšC)

x 10).

For PCBs with thicknesses of 0.06 inches [1.5

mm] or greater, an STII value of 215 or larger is recommended. The STII

concept is still not widely used, however, many, but by no means all,

base materials offered by suppliers meet and exceed an STII-value of

215.

The reason for the importance of these

properties comes from the thermo-physical loading that the PCB

interconnect structures, such as plated-through holes (PTHs),

plated-through vias (PTVs), buried vias and even micro-vias experience

during the temperature excursions used in the lead-free soldering

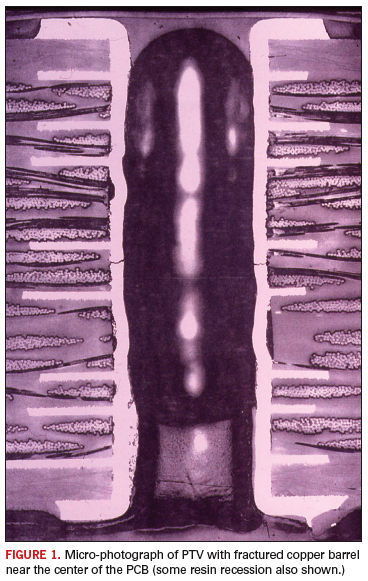

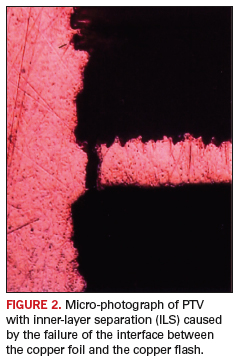

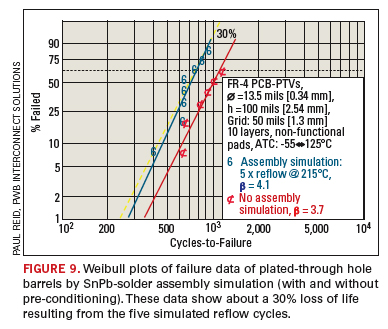

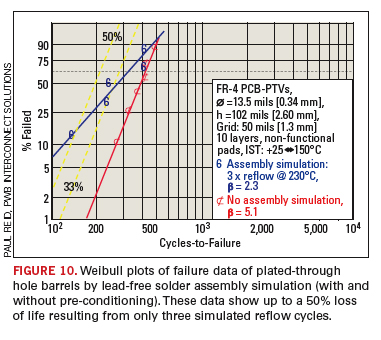

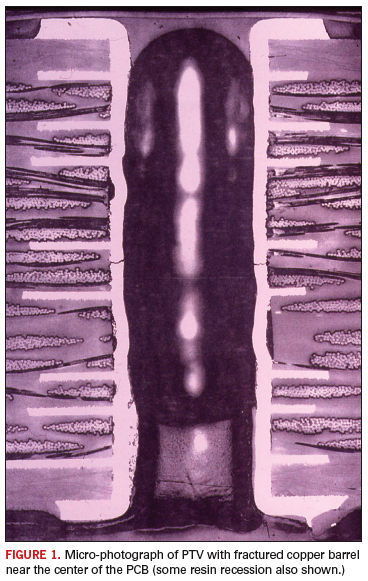

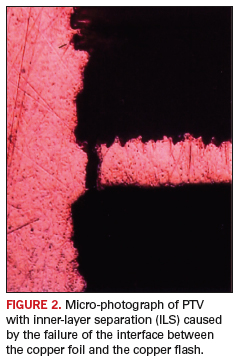

process. Failures such as via barrel cracking (Figure 1) and innerlayer post separation (Figure 2) can be avoided by proper design. The resin recession, shown in Figure 1, does not have any real reliability consequences.

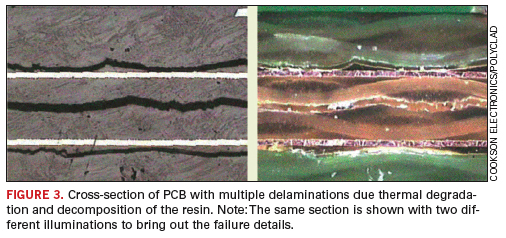

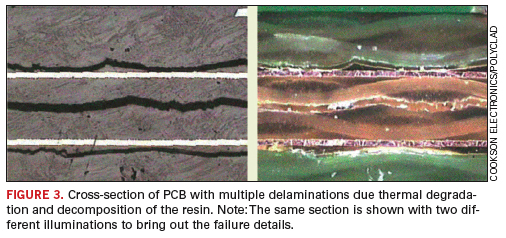

In

order to reduce the z-axis thermal expansion, various fillers are added

to the basic PCB resin systems. In some cases, this reduces the

strength of the material and leads to cohesive delamination failures as

seen in Figure 3. Unlike adhesive failures resulting

from a delamination at the copper-to-resin interface, cohesive

delamination is limited to the dielectric material itself.

Desmear

Lead-free

compatible, high-Tg (170-180ËšC) materials often use phenolics as curing

agents. The resistance of these laminate resins to desmear chemistries

is substantially higher than the dicy-cured, high-Tg materials.

Therefore, desmear procedures may require re-evaluation. Any new

laminate material should not be assumed to be a drop-in replacement. If

the desmear cycle has not been optimized, there will be poor hole wall

topography and the potential for residual resin smear and plating

defects.

Design and Specifications

Because

of these issues, new PCB base materials designed for lead-free solder

assembly need not only be properly selected according to their data

sheet information, but also should have coupons tested in the product

configuration to demonstrate their ability to meet quality and

reliability requirements. In fact, some in the industry prefer to

specify the capabilities of the finished product instead of specifying

material properties. The argument advanced is that it is not only the

importance of properties of the raw materials used, but also the impact

of the processing environment that ultimately determines the product’s

success.

Product capability requirements could be

given in terms of the maximum expected temperatures reached during

lead-free soldering processes and total exposure time, for example,

280ËšC for 3 minutes, inclusive of all soldering processes – HASL,

reflow, wave, as well as rework and repair. Alternatively, one could

specify solder floats or dips, for example 288ËšC for 3 to 5 cycles of a

specific time. The coupons would have to withstand these exposures

without delamination, barrel cracking and/or inner-layer separation.

It

has also been suggested that a cyclic “time-to-delamination” protocol

be introduced. So, perhaps in addition to or as a replacement for a

T-260 test, a cT-260 value could be generated by first conditioning the

boards by thermal cycling to 260ËšC or some higher temperature for X

number of cycles, to simulate the assembly process. For example, 6

thermal cycles could be used to simulate 3 reflow and 3 rework cycles.

After the thermal cycles have been completed, the PCB would be

subjected to the standard T-260ËšC testing until delamination occurs. It

has been reported that some “high performance” resin systems degrade

with thermal cycling much more readily than from a single thermal

excursion to 260ËšC or even 288ËšC, and that materials with poor cT-260

results usually do not fail because of delamination, but because of

barrel cracks of the vias.

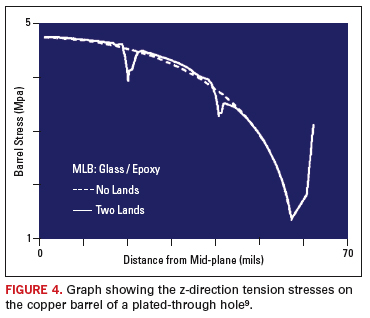

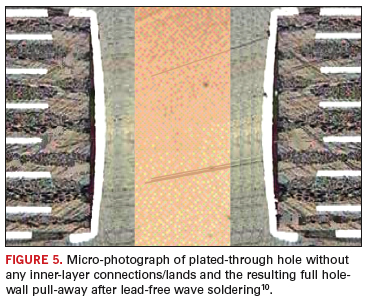

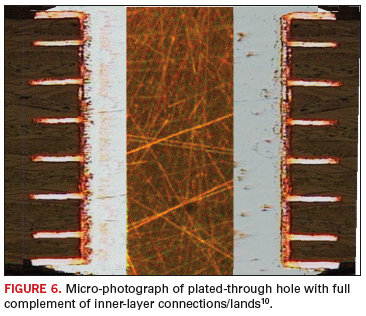

Non-Functional Lands

A

common assumption has been that the removal of non-functional lands

(NFLs) has no impact on reliability, but this assumption needs to be

rethought in light of the higher lead-free soldering temperatures,

which can reach temperatures of 265 to 280ËšC when soldering with some

lead-free solders.

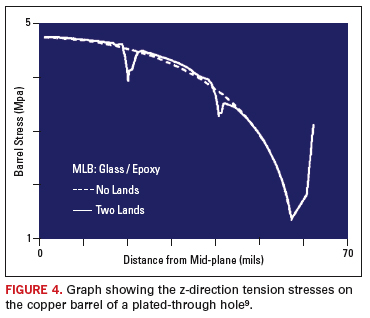

Previously it was shown that there was no significant impact on barrel stresses when NFLs were removed, as can be seen in Figure 4.

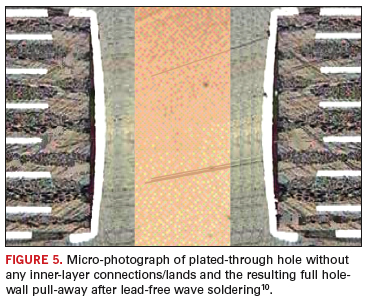

However, recent testing has shown the removal of NFL to be nowhere near

as benign for assemblies undergoing the lead-free soldering process as

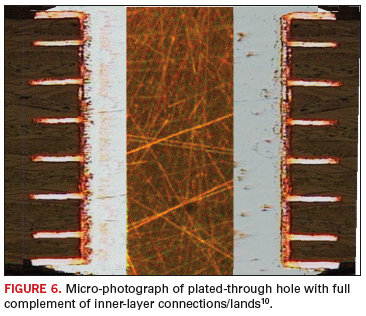

had been tacitly assumed. Figure 5 shows some recent industry experience with PTHs in PCBs that reached the “red flag”-level at an aspect ratio of 4-to-1. In Figure 6,

the same PCB is shown with a full complement of non-functional lands

(NFLs) and it shows no wall separation or resin recession.

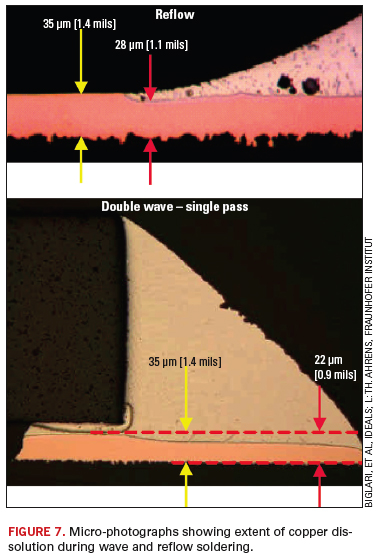

Copper Dissolution and Plated Copper Thickness

It

was only recently that the IPC-specification for minimum copper plating

was lowered from 1.0 mils to 0.8 mils [25 to 20 µm]. This was done in

response to the increased costs and time required to plating 1.0 mils

of copper in the center of the hole in high aspect ratio boards. These

cost are associated with the lower plating current densities required

to plate uniform copper into high aspect ratio plated-through vias

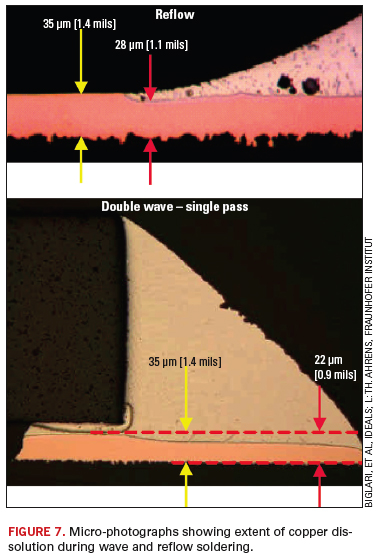

The

higher soldering temperatures, together with the very high tin content

of lead-free solders, leads to a significant increase in the rates at

which copper is dissolved during soldering processes. This can be seen Figure 7.

Reductions in copper thickness by as much as 12 µm [0.5 mils] have been

reported. The minimum copper plating thickness may need to be increased

in light of these finding to perhaps 1.2 mils [30 µm] to allow for the

potential dissolution without a negative affect on PTH reliability.

Increasing the copper barrel plating thickness can improve the survival

and long-term reliability of PCBs that will undergo the higher

soldering temperatures used with lead-free solders, and this increased

thickness will need to be specified by the designer.

Moisture Absorption and Bake-Out

Moisture

absorption can play a significant role in whether a PCB can survive the

high temperatures required for lead-free soldering. Thus, it is

imperative that both test coupons and production PCBs undergo adequate

moisture bake-outs just prior to assembly. These bake-dry or vacuum

bake procedures should be done at temperatures not to exceed 105ËšC for

the number of hours (up to 24) required to sufficiently remove moisture

from the PCBs.

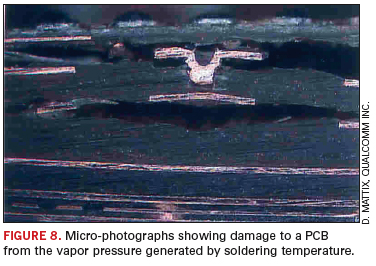

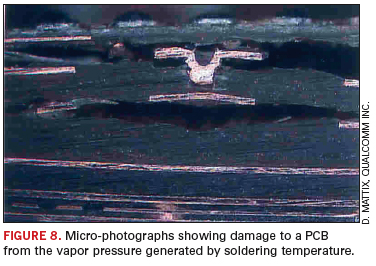

Vapor pressure within the PCBs can

cause both cohesive and adhesive failure modes, depending on where the

weakest bonds are located, whereas thermal decomposition due to

inadequate thermal stability leads predominantly to cohesive failures.

It should be noted that the vapor pressure within a PCB roughly doubles

from 220ËšC to 260ËšC. The consequences of high vapor pressure can be

seen in Figure 8.

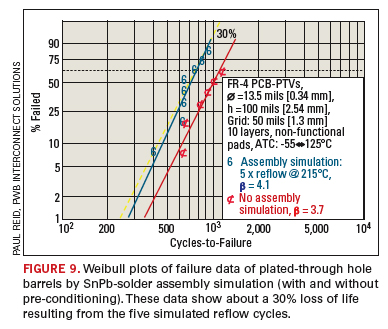

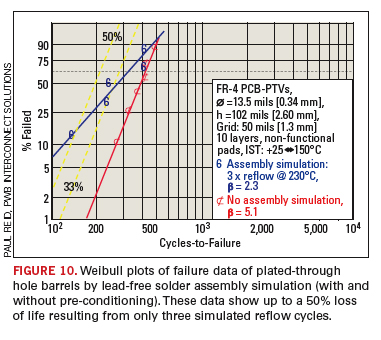

Testing

PCB testing using IST (Interconnect Stress Testing) as per IPC–TM-650, 2.6.2611, or HATS (Highly Accelerated Thermal Shock) as per IPC-TM-2.6.7.2B12 assures primarily long-term reliability in terms of operational conditions.

Preconditioning,

such as subjecting a PCB to 5 or 6 cycles of solder reflow or vapor

phase exposure up to the maximum soldering temperature could reveal

possible damage resulting from the high lead-free soldering

environment. Such preconditioning shows that temperature excursions to

solder reflow temperatures can reduce the PCB long-term reliability by

as much as 50%, as illustrated in Figures 9 and 10.

The difference in the samples in Figures 9 and 10 is the increase in

preconditioning temperature, which is still not at the level expected

for lead-free reflow soldering. PCD&F

REFERENCES

1. Engelmaier, W., “Recommendations for PCB FAB Notes and

Specifications in Printed Circuit Board Drawings for SnPb and Lead-Free

Soldering Assemblies, the Qualification of PCB Shops and Activities to

Assure Continued Quality, v.07,” White Paper/Multi-Client Study,

Engelmaier Associates, L.C., February 2007.

2. IPC-4101 “Laminate/Prepreg Materials Standard for Printed Boards,”

The Institute for Interconnecting and Packaging Electronic Circuits,

Bannockburn, IL, Rev. B June 2006.

3. IPC-Test Methods Manual, IPC-TM-650, 2.4.24C, “Glass Transition

Temperature and Cure Factor by DSC,” The Institute for Interconnecting

and Packaging Electronic Circuits, Northbrook, IL, December 1994.

4. IPC-Test Methods Manual, IPC-TM-650, 2.4.25C, “Glass Transition

Temperature and Z-Axis Thermal Expansion by TMA,” The Institute for

Interconnecting and Packaging Electronic Circuits, Northbrook, IL,

December 1994.

5. IPC-Test Methods Manual, IPC-TM-650, 2.4.24.4, “Glass Transition

Temperature and Thermal Expansion of Materials Used In High Density

Interconnection (HDI) and Microvias-DMA Method,” The Institute for

Interconnecting and Packaging Electronic Circuits, Northbrook, IL,

November 1998.

6. IPC-Test Methods Manual, IPC-TM-650, 2.4.24.6, “Decomposition

Temperature Td of Laminate Material Using TGA,” The Institute for

Interconnecting and Packaging Electronic Circuits, Northbrook, IL,

April 2006.

7. IPC-Test Methods Manual, IPC-TM-650, 2.4.41, “Coefficient of Linear

Thermal Expansion of Electrical Insulating Boards,” The Institute for

Interconnecting and Packaging Electronic Circuits, Northbrook, IL,

March 1986.

8. IPC-Test Methods Manual, IPC-TM-650, 2.4.24.1, “Time to Delamination

(TMA Method),” The Institute for Interconnecting and Packaging

Electronic Circuits, Northbrook, IL, December 1994.

9. Bhandarkar, S. M., A. Dasgupta, D. Barker, M. Pecht, and W.

Engelmaier, “Thermo-Mechanical Stress Analysis of Plated Through Hole

Structures,” ASME J. Electronic Packaging, Vol. 114, No. 1, March 1992,

pp. 8-13.

10. Engelmaier, W., “Interconnect Failures and Design for Reliability

for Plated-Through Holes/Vias (PTHs/PTVs), Workshop Notes, Engelmaier

Associates, L.C., 2007.

11. IPC-Test Methods Manual, IPC-TM-650, 2.6.26, “DC Current Induced

Thermal Cycling Test,” The Institute for Interconnecting and Packaging

Electronic Circuits, Northbrook, IL, May 2001.

12. IPC-Test Methods Manual, IPC-TM-650, 2.6.7.2B, “Thermal Shock,

Continuity and Microsection, Printed Board,” The Institute for

Interconnecting and Packaging Electronic Circuits, Northbrook, IL, May

2004.

Werner

Engelmaier, known as “Mr. Reliability” in the industry, is president of

Engelmaier Associates, L.C., (engelmaier.com), a firm providing

consulting services on reliability, manufacturing and processing

aspects of electronic packaging and interconnection technology;

This email address is being protected from spambots. You need JavaScript enabled to view it..