An interview with Chantal Holloway and Guillaume Turgeon – two of the

2007 winners of the Mentor Graphics PCB Technology Leadership Awards.

Category: Industrial control, instrumentation, security & medical.

Company Name: Gage Applied Technologies Inc.

Designers: Chantal Holloway, Guillaume Turgeon

Design Description: High-speed mixed signal board.

The

PCB Technology Leadership Awards have been around for 20 years, and

provide PCB designers with an opportunity to have their best designs

judged by a panel of experts. The categories included:

- PC Computers and Peripherals

- Consumer Electronics & Handhelds

- Industrial Control, Instrumentation, Security & Medical

- Military & Aerospace

- Telecommunication Switches, Network Servers, Base Stations and Computer Mainframes

- Transportation and Automotive

There is also an award for best overall design.

In

2007 designers came from around the world to participate, heralding

from Germany, Switzerland, China, Norway, Singapore, Austria, Canada,

Korea, India, Israel, Portugal, the United States and the United

Kingdom.

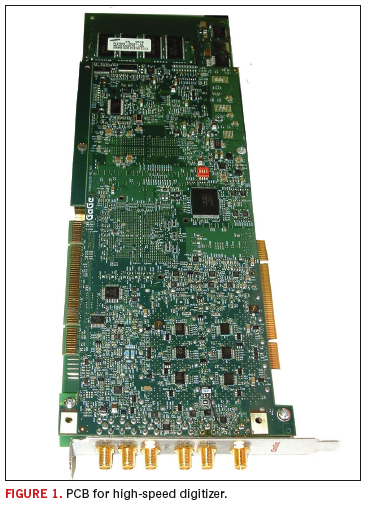

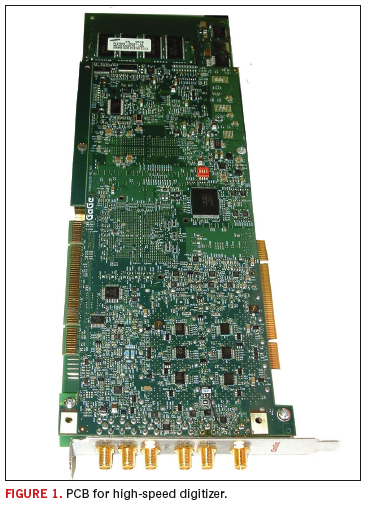

The design team of Holloway and Turgeon took

the gold in the industrial control, instrumentation, security and

medical division. Their design, a high-speed mixed signal board with

both electrical and mechanicals constraints, resulted in a 12-layer

stack up with split and mixed signal planes. In order to optimize the

opposing requirements of the analog and digital sections of the PCB, it

was necessary to develop a split plane and routing plan that addressed

potential cross talk between the PCB domains.

The

original design challenge was to upgrade the PCB for improved

performance while lowering the cost. The previous design had used two

stacked PCBs joined by a connector. The new single PCB surpassed the

targeted design parameters. It will be manufactured at a lower cost

than the previous two board design, accommodated a higher sampling rate

digitizer, ran at higher speeds than expected, and had lower power

consumption.

The challenges included designing two

different products, one that would be used in an add-on board

configuration and one that would be a stand-alone design. There were

considerable high-speed analog front-end constraints. Routing was

particularly difficult, with matched length differential pairs and 452

high-speed nets. Gage used a new design tool, specifically developed

for high speed routing, to manage the difficulties of routing CLK

signals, differential pairs, and high-speed signals.

A photo of the PCB can be seen in Figure 1.

One of the main challenges with this design was the requirement that a

single PCB would be used to accommodate different final product

configurations. This feature is customized during the assembly phase.

The design used two duplicate Master/ Slave interfaces to accommodate

standalone PCI or baseboard connection. This places some restrictions

on component placement.

- The board statistics are as follows:

- Board Dimensions: 9.633 x 3.55 inches

- Board Thickness: 0.062 inch

- Usage Area: 34.19715 inches

- Laminate Material: Polyclad 370HR RoHS Compliant for Lead Free Assembly

- Total Number of Layers: 12

- Number of Signal Layers: 8

- Number of Power Planes: 4

- Minimum Spacing: 4.25 mils

- Minimum Line Width: 3.75 mils

- Minimum Vias Size: 10 mils

- Minimum Pad Size: 19 mils

- Number of Vias: 3,983

- Number of High-Speed Nets: 452

- Number of Pin-to-Pin Connections: 7,445

- Component Placement: Double-sided

- Number of Components: 2,253

- Total Component Area: 668.00

- Number of Component Pins: 9,353

- Minimum Pitch: 0.5 mm

- Component Complexity: up to 1,020 pin BGA

When

asked about the most challenging aspects of the design, Holloway and

Turgeon responded, “One main challenge of this board was to accommodate

different final product configurations utilizing a single PCB layout.”

They continued, “A minimum trace length in addition to matched length

routing strategy was used for the DDR-II Interface between the high

density BGAS and the SODIMM to the termination resistors.” Same length

matched routing from the SODIMM attached to the baseboard connector

provided one configuration. A component free area 1.300 x 2.500 inch

for memory module insertion accommodated the second configuration.

The

end product is a next generation high-speed digitizer. The flexibility

provided by the reconfigurable PCB allows for one or two channel

sampling at rates up to 3.2 GS/s. With the product name Rabbit, this

digitizer, made possible by the PCB design excellence of the Holloway

and Turgeon team, promises to make a significant impact on the market

with its higher speed and larger sampling capability. PCD&F

Kathy Nargi-Toth is editor of Printed Circuit Design & Fab.