Tips for avoiding EMI and simplifying debugging.

Tips for avoiding EMI and simplifying debugging.

Power distribution on a PCB can come in a number of forms. The three most common methods are:

Route power and ground.

Use surface layer floods.

Use internal planes.

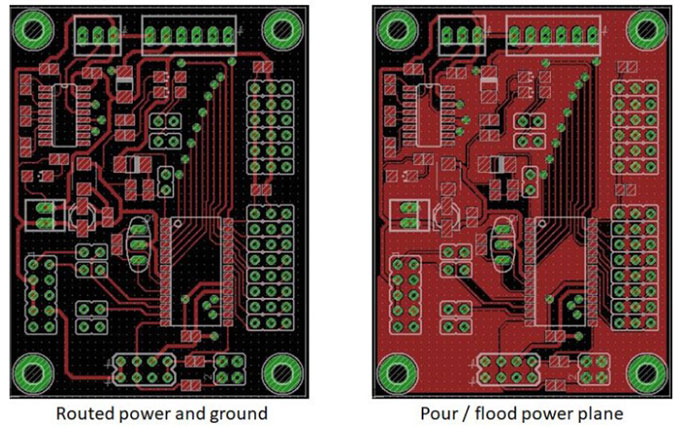

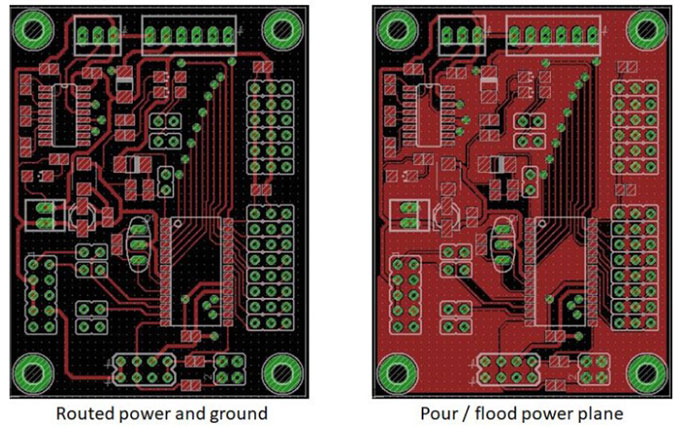

After component positioning, look at power and ground distribution. With a two-layer board, the options are limited to individually routing power and ground, or using a polygon fill, also called a flood or pour (FIGURE 1).

Figure 1. A routed power and ground (left) and pour (flood) power plane (right).

For simple low-speed layouts, it’s common to route power just like any other signal. You’ll typically use a wider trace, which you can set manually, or with design rules. Drawing a polygon in the board shape, and giving it the same name as the power or ground signals, may make the job easier. Keep in mind, however, that this can result with parts of a ground plane disconnected from the rest of the board. This is called an orphan. Some CAD error checks will spot such a problem and some won’t.

I made that mistake not long ago, as described in a blog item last September titled “Mistakes Were Made – Too Much Ground Isolation” (http://scrm.it/gndmistake).

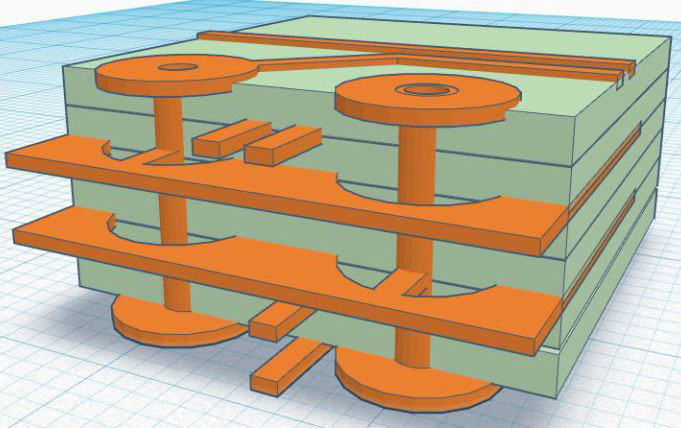

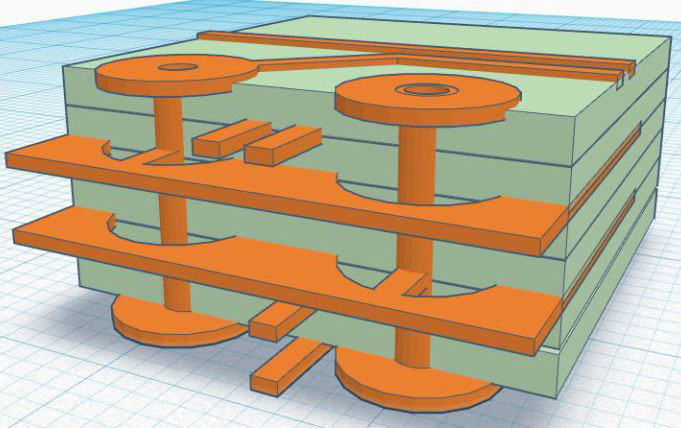

For a four (or more) layer board, common practice is to designate one of the internal layers for ground, and one for power (FIGURE 2). Doing so can leave more room for signal routing, reduce EMI, and leave a cleaner-looking, easier-to-debug board. It also reduces the chances of having orphan ground or power areas, as I warned against in the “Mistakes” post.

Figure 2. For boards of four or more layers, designate one layer for ground and one for power.

Duane Benson is marketing manager and chief technology champion at Screaming Circuits (screamingcircuits.com); This email address is being protected from spambots. You need JavaScript enabled to view it..