The best defense against voids is to understand the processes that can cause the defect.

In this edition of Positive Plating, we will discuss voids that are directly attriuted to the electroless deposition process.

Voids

in the electroless copper deposit can be caused by a variety of

reasons, but incorrect or improper maintenance of chemical

concentrations or operating parameters are most often the culprits.

Assuming that the desmear operation and drilling are within

specifications, the next step is to concentrate on the electroless

copper process itself. It is important to recognize that the PTH

process is an integrated operation. This means that the various process

steps are interdependent on each other. For example, the

cleaner-conditioner step influences the degree of catalyst adsorption,

which in turn influences copper deposition. Thus, one can still produce

voids but not necessarily because of the electroless copper solution

itself.

After the desmear operation, the next step is

to clean and condition the holes. The cleaner conditioner functions as

a super wetting agent that promotes catalyst adsorption onto the glass

and resin of the hole wall. The key is to avoid incomplete conditioning

of the holes, but not over-condition due to extended dwell times, poor

rinsing or a higher than normal concentration of the conditioning

chemistry.

The cleaner conditioner is generally a

mildly alkaline solution containing wetting agents. These wetting

agents are often formulated with cationic surfactants or

polyelectrolytes that aid in the adsorption process by neutralizing the

negative charges on the hole wall particularly the glass rich areas.

The supplier must formulate these conditioners so as to form a

monolayer of conditioner on the hole wall, as opposed to the multilayer

coatings that some cationic surfactants produce. Generally,

insufficient conditioning will lead to poor catalyst adsorption,

particularly on the glass fibers, which leads to poor electroless

copper deposition.

The catalyst provides the medium

that will permit the actual deposition of the electroless copper onto

the hole wall. The activator is a colloidal catalytic solution formed

by the admixture of palladium chloride salts, a stannous salt in molar

excess of the catalytic metal salt (palladium) in an acidic medium. The

tin is required to keep the palladium in its active state and prevent

the precious metal from precipitating, which would render the catalyst

inactive.

Insufficient amounts of catalyst will

reduce the amount of copper deposited in the hole. This can lead to

either voids, reduced electroless copper plating thickness, or both.

Other key parameters to monitor are:

- Catalyst temperature too low or dwell time insufficient – both will reduce catalyst effectiveness and can lead to voids.

- Low palladium content in the catalyst - this must be analyzed and maintained within the proper concentration window.

- Copper

contamination in the catalyst-operators must do everything possible to

reduce copper ion drag-in from the micro-etch. A related issue here is

the “pre-dip,” a salt-water solution designed to provide common ion

drag-in to the catalyst solution. No rinse is required. The main

purpose is to reduce the chance for copper contamination in the

catalyst so the pre-dip should be changed often to reduce copper

drag-in potential. Generally, 500-700 ppm of copper in the catalyst

will act as a catalytic poison, and can lead to voids.

- Oxidation

of the stannous ions will lead to subsequent catalyst instability. The

palladium will precipitate, thus reducing its catalytic activity.

- The

quality of the rinse after catalyzation should not be overlooked. The

rinse will remove excess catalyst and convert the stannous tin to

stannic, with the water taking on a cloudy appearance due to the

conversion of the stannous tin. This process actually aids in the

removal of tin in the post activator step (accelerator), that exposes

the palladium for subsequent electroless copper deposition.

- Some

post activators perform their function by oxidizing the stannous tin

layer that surrounds the palladium to stannic tin, creating a more

catalytically active particle. Other accelerators acts as a tin

stripping solution, solubilizing the tin and exposing the palladium.

Regardless of the mechanism or chemistry utilized for post activation,

insufficient acceleration will reduce the copper deposition reaction.

When this occurs, voids and thin deposits are the result.

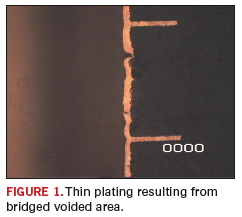

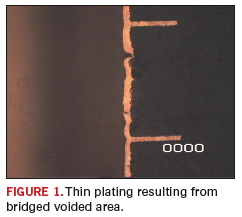

An example of thin plating is shown in Figure 1.

Several causes are possible here, including insufficient conditioning

of the glass fibers, insufficient catalyst adsorption or inadequate

acceleration. Issues that can lead to thin plating are often also

associated with voids. Understand how the various processes interact

can help you trouble shoot the process and resolved the problems.

Remember,

the best defense against voids and other potential defects is a good

offense! Do your homework and make sure you have a good understanding

of all processes that can contribute to defects. PCD&F

Michael Carano is vice president of OM Group Inc. and can be reached at This email address is being protected from spambots. You need JavaScript enabled to view it..