As design disciplines converge, the ability to display, exchange

and work in 3D will become an essential part of the electronic product

development process.

In today’s global market, the

pressure to create smaller, more intelligent products in less time is

forcing design engineers to critically reassess and revise the overall

product design process – from concept right through to manufacture.

The

need for change is further fueled by the rapid development of

electronics technology, which in a series of evolutionary steps has

altered the fundamental processes we use to create today’s electronic

products. The emerging challenge for product development teams is

managing and working with these increasingly interdependent processes

while meeting production deadlines.

As electronic

products and the processes used to create them evolve, the

fundamentally dissimilar worlds of electronic and mechanical design

need to work in harmony. To stay competitive in today’s market,

designers must adopt systems that unify the design process and allow

the smooth flow of design data across the electromechanical divide (Figure 1).

|

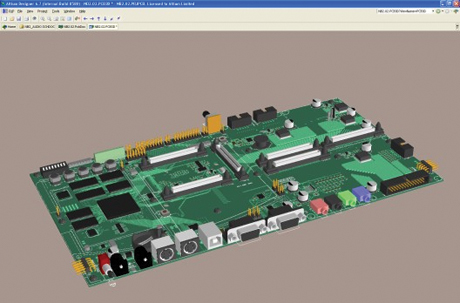

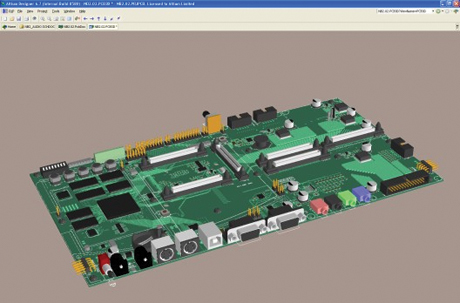

FIGURE 1.

Shown as rendered in an advanced board layout system, this assembly

includes 3D component models imported from MCAD STEP files. The entire

board assembly can be exported to an MCAD application as a 3D STEP

file, allowing ECAD-MCAD co-design.

|

Electronics

design, however, is typically viewed as a set of disparate design

disciplines; each requiring their own design environments -- hardware

design, programmable logic design and software development. This

divisive approach hampers efficient collaboration with the wider

product development process. Unifying electronic design, however,

creates the environment required for true design interaction and

collaboration in all stages of electronic design flow. By incorporating

the processes needed in a single application, a unified electronic

development system shares design data at a native level and manages

design information globally. The seamless flow of information between

design stages opens the door to flexible, interactive and innovative

design practices that support a fluid division between hardware and

software.

The efficiencies and high level of design

collaboration delivered by a unified electronic product development

system extend to all levels of the design flow – from concept though to

manufacture. The central control of design information and data allows

all those involved in the product development process to work in a

connected and collaborative way, all the way through to document

handling, parts management and manufacturing.

In the

bigger picture, the need for effective design collaboration extends to

those outside the immediate sphere of electronic design. An

increasingly important part of the evolution in product development is

interaction between the electronic and mechanical aspects of a design,

where the incessant need for smaller and more functional packaging

forces the two to be intimately connected – in both a physical sense

and in development.

Board assemblies now typically

hold all of the external hardware such as connectors, keypads and

displays, while the product case assembly neatly exposes these to the

user. Gone are the days when a product case merely housed the

electronic assemblies and the separate hardware elements were connected

via interwiring. In short, packaging has now moved from being a simple

container to a tightly integrated part of the product.

Converging MCAD-ECAD Design

More

than ever before, a product’s packaging must take into account the

physical aspects of the internal electronics while, in turn, the

electronics assembly – in practice the board design – must allow for

the physical style and functionality of the package design. This

increased interdependency of design processes is in line with the

overall trend in electronic product development where previously

isolated stages in the design flow must now efficiently interact. From

design capture through to manufacturing, maintaining a competitive edge

in the market requires tools and processes that support collaboration

at all levels of development.

Efficiently bridging

the gap between the mechanical and electronic design processes is,

therefore, becoming crucial for collaborative and successful product

development. However, rather than simply passing raw dimensioning and

positional data from the ECAD to MCAD environment, what is needed is a

design tool that allows a bi-directional flow of comprehensive 3D data

between those domains. In the ECAD world, this means an ability to

import and seamlessly integrate 3D component data from an MCAD

environment; then pass a full and accurate 3D representation of the

board assembly back to the MCAD domain (Figure 2).

|

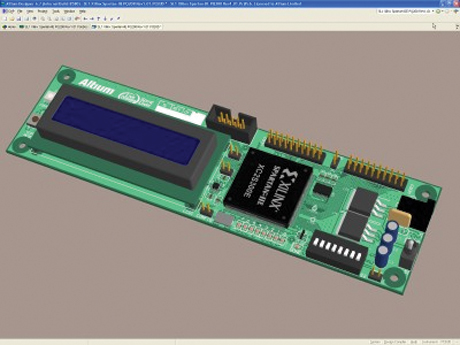

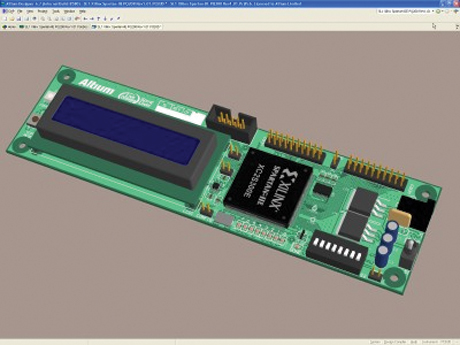

FIGURE 2.

Effective and collaborative ECAD-MCAD design relies on the smooth,

bi-directional flow of design data using a robust system-independent

format such as the STEP standard.

|

This

higher-level process also offers the opportunity of passing

comprehensive, component-inclusive board data to the mechanical design

environment earlier in the product development cycle, allowing

ECAD-MCAD co-design. What’s more, the gain in design flow efficiency is

further enhanced by the reduced need for a prototype board assembly to

be on hand during the MCAD design stage. With comprehensive 3D data

exchange, the mechanical designer can have full dimensional information

on hand even if the board is still being routed in the ECAD environment.

To

harness this potential and prepare your design system for the ongoing

convergence in the MCAD and ECAD worlds, the minimum requirement is for

an electronics design system that allows 3D models to be imported and

attached to components. Such a system should also allow you to view and

export an accurate 3D rendition of a complete board design. Ultimately,

this free exchange of 3D design data creates the opportunity for a high

level of interaction between the mechanical and electrical design

environments, promoting the productivity and innovation benefits of

MCAD-ECAD design collaboration.

Electromechanical Design Flow

As

electronic products shrink in size, production deadlines shorten and

the industry moves toward “soft” electronic design solutions, the

ability to efficiently share information across all design processes is

becoming crucial. A unified product development environment offers this

capability at a fundamental level through its ability to complete all

stages of electronic design – hardware, programmable hardware and

embedded software – within a single environment.

The

natural extension of this unified data-sharing concept is to encompass

the 3D modeling data that must pass to and from the mechanical design

domain. In practice, this means implementing ECAD and MCAD systems that

support 3D data exchange at a high level, which draws the environments

together to create a holistic design environment and more efficient

product development workflow.

This approach is

gaining rapid momentum. Take, for example, R&D design-house 3G

Engineering, which has embraced ECAD-MCAD integration to simplify the

overall design process while reducing the company’s design turnaround

times and product development costs. As a specialist in the development

of custom-built turnkey electromechanical products for industry, 3G’s

in-house electronic and mechanical design processes are highly

interdependent and need to be approached as a single, cohesive task.

3G

Engineering’s consolidated workflow is based on a unified ECAD system

that supports both 3D modeling and the bi-directional exchange of 3D

design data.

The ECAD system can bring together the

software, hardware and programmable hardware parts of the design

process into a single application and has allowed the 3G engineers to

draw the company’s MCAD system into the overall product development

process. The result is a homogeneous workflow that allows a high level

of interaction between the ECAD and MCAD design environments.

The

data exchange capability is used to good effect by 3G engineers who

first develop and refine a new project’s physical properties in the

MCAD environment, then determine the volumetric dimensions of the space

available for its electronic subsystems. These preliminary dimensions

are transferred to the ECAD environment – generally as a proposed 2D

board shape – very early in the design cycle, so the board layout

process can proceed in parallel with the MCAD design work.

The

board assembly is subsequently developed using components with matching

3D models that are sourced from the parts manufacturers or, if

unavailable, created from scratch in an MCAD environment. These custom

3D representations are transferred to an ECAD system as STEP 3D data

files, where they can be attached to the matching components in the

system’s libraries. 3G Engineering is progressively building the 3D

elements within the company’s ECAD libraries but sees this as a future

investment that easily justifies the work involved in collecting and

creating 3D component models.

Ultimately the fruits

of that labor become apparent when a board assembly has all components

in place. At this point, the 3G engineers can create and view a

meaningful 3D representation of the board assembly in the ECAD system,

then transfer that rendered image into MCAD as a STEP 3D data file. The

3D representation is then checked for 3D dimensional accuracy in the

MCAD environment where, almost literally, it can be fitted into the

product’s enclosure or allocated cavity space. According to 3G, at this

point, there is rarely a need for design revisions to correct for

physical discrepancies between the electrical and mechanical assemblies

because, thanks to the initial flow of accurate 2D/3D data, the

engineers are able to simply “get it right the first time.”

By

basing its product development process on a unified ECAD solution that

smoothly interconnects to the MCAD environment, 3G Engineering is able

to tackle product design as a single engineering challenge, rather than

as set of disconnected design problems that are resolved in isolation –

and finally brought together. The company’s engineers can confidently

develop the ECAD and MCAD elements of a design in parallel, ECAD-MCAD

amalgamation errors are rare, and the overall product design process is

faster and simpler. According to 3G, design processes that formerly

took weeks with the disconnected ECAD-MCAD systems used in the past can

now be completed in just days – a considerable asset for a company that

holds a competitive advantage based on innovation and rapid product

development times.

As ECAD and MCAD design

disciplines converge, it is becoming increasingly important for all

design engineering teams to take into account how that relationship

works and its ultimate effect on the overall product development

process.

For those accustomed to working in the

traditional 2D space of ECAD design capture and board design, it is now

important to consider the benefits of embracing the 3D design space and

its connection with the entire production chain. The ability to

display, exchange and work with 3D rendered objects in your electronic

design system is not just a nice add-on feature set and is certainly

not a gimmick. As design disciplines converge and collaborate at a

higher level, it has become an inherent and essential part of the

electronic product development process that will play an increasingly

important role into the future. PCD&F

Rob Evans is in technical marketing with Altium Ltd. He can be reached at This email address is being protected from spambots. You need JavaScript enabled to view it..