When should machine soldering be used instead of manual?

High-mix production is the mainstay of many electronics assembly plants. Lot sizes and board complexities vary, and boards are often mixed technology, comprising a blend of both surface-mount and through-hole technology. Modularizing a production line enables a clear distinction between one type of assembly process and another. This month, we look at the decision-making of routing a circuit board through-hand assembly vs. automated selective soldering. This assumes a modern factory where a job can be routed to the selective soldering machine module, the hand assembly bench, or a combination.

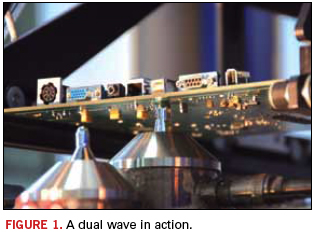

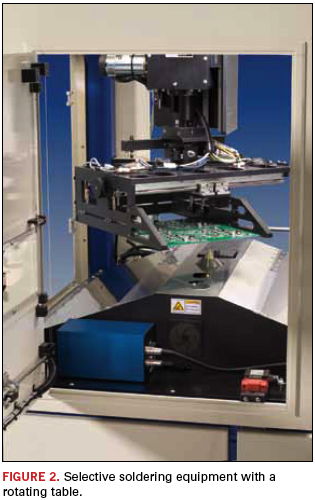

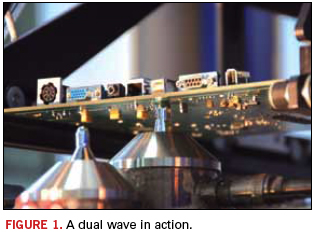

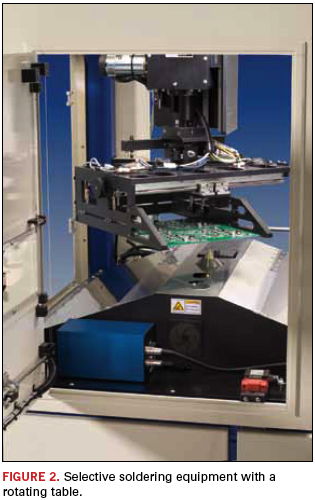

Selective soldering machines are an automated way to solder through-hole components on a circuit board. The machine contains a heated solder tank that generates a small fountain of molten solder approximately 0.375" in height and 0.25" in diameter. The leads to be soldered are positioned into this fountain of molten liquid for soldering (Figure 1) using a programmable x-y translation table. The operator places the PCB into the motorized x-y table (Figure 2) and by using a program (either input by the operator or imported from circuit board drawings), directs the board to move above the solder jet, lower a specific component into the solder fountain for soldering, raise the board, and translate the board to the next component to be soldered.

Modularizing the production plant enables the manager to match the production rate and precision requirements of a specific job with the correct machine or machine operation. A clear example of this modular approach is a comparison between routing a job between a hand-soldering operation and a selective soldering machine. Some decisions are obvious. After programming and setup of a selective solder machine, the process operation will always yield the same quality solder joint, repeatably. Hand soldering results can vary depending on the operator. This variation can be minimized if the assemblers are all trained to an industry standard like J-STD-001, Requirements for Soldered Electrical and Electronic Assemblies. This standard must be applied to the finished assembly, regardless of method of assembly, manual or automated.

Although surface mount is the dominant form of component today, some components may only be available in a through-hole format (such as power transistors and connectors). When a modular production line is set up, the decision of routing the job through the selective soldering machine may be based on the number of solder joints. If there are dozens to hundreds of joints to be soldered, the selective soldering path is a superior choice over a manual bench operation. If there are only a few joints to be soldered, hand assembly is a good choice.

Whether using manual or selective soldering, the board must be inspected by a human operator. This can reduce the efficiency of the automated process. With this in mind, the best modular location for the selective soldering machine might be in the hand-assembly department, where the employees have the necessary experience to inspect the output of the selective soldering machine to industry standards.

ACI Technologies Inc. (aciusa.org) is the National Center of Excellence in Electronics Manufacturing, specializing in manufacturing services, IPC standards and manufacturing training, failure analysis and other analytical services.