Successful design/characterization of PCB high-speed interfaces frequently demand analyses of timing margins and jitter.

The digital signal integrity as a discipline1

came into existence in the 1960s, and three main signaling schemes have

since emerged. These signaling methods include common clock, source

synchronous and high-speed serial.

Many SI issues in

modern digital interfaces are caused by reflection, crosstalk,

attenuation, resonances, and power distribution noise. However, the

actual failure mechanism does not involve voltage waveforms (at input

of the receiver ICs), but a timing relationship1 between

those waveforms and the clock that samples the signal. It has been

observed that “ninety percent of signal integrity problems are timing

problems2.”

Several concepts and

mathematical formulae governing common clock and source synchronous

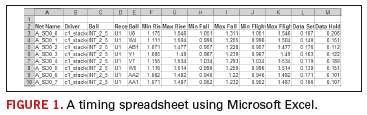

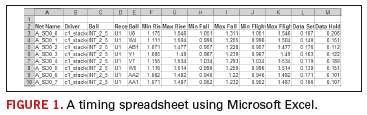

timing were described in previous columns3,4. One way to apply timing equations is by generating a spreadsheet to compute allowable worst (and best) case flight times5 and timing budgets. Figure 1 displays section of a timing spreadsheet created utilizing Microsoft Excel.

The

spreadsheet was generated to summarize the timing results for various

nets of a high-speed parallel bus. The column entries display net

names, driver reference designations (plus pin names), receiver

designations (and pin names), minimum and maximum rise times, minimum

and maximum flight times, setup and hold margins. For a bi-directional

bus, it is necessary to solve the min/max flight times for each signal

direction. Such spreadsheets can readily indicate which nets have

failed setup or hold timing margins and hence require an improvement to

meet timing requirements.

Timing budgets may be also presented in table format6.

Several programs are available to aid system timing analysis and

verification. Such software include Timing Designer from Forte Design

Systems, Timing Diagrammer Pro from Synaptic CAD, Inc, TimingTool (a

free, intranet-based timingtool.com timing diagram editor) and Tau7.

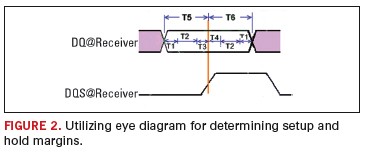

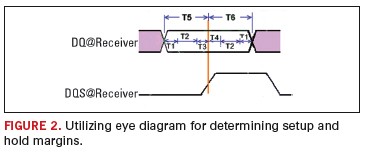

Eye diagrams also offer an effective means for ascertaining the setup / hold margins for source synchronous buses8, centering clock transitions in the middle of the data eye2 and for deriving timing equations4.

Figure 2

illustrates how setup and hold margins for a source synchronous signals

may be determined via an eye diagram. Here T1 represents timing margin,

T2 equals skew, T3 is setup time and T4 is hold time, T5 is “valid

before time” (i.e., the time before the strobe occurs when the data

signal will be valid).

T6 is “valid after time” (i.e., the time after the strobe occurs for which the data is still valid).

When

timing failures (or signal quality violations) are detected for a

signal net, the signal performance may improved by altering/enhancing

termination, topology9, 10 or technology (sometimes called the “the three Ts”).

As clock frequencies increase, timing becomes more critical11.

Timing margins for parallel bus architectures diminish and signal

flight times (propagation delays) are reduced to picoseconds. Because

such tight tolerances are often not feasible to obtain, the serial data

bus architectures have emerged and gained popularity for the fastest

systems.

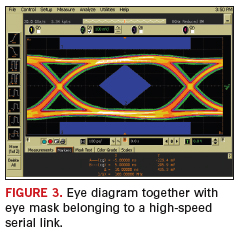

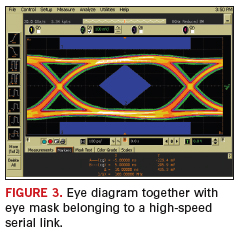

Eye diagrams provide a preferred/intuitive

means for timing analysis of high-speed differential serial links (with

embedded clocks). Eye height is the eye opening in the amplitude domain

and eye width relates to signal timing and jitter12. Eye

masks are applied to more easily determine pass/fail conditions. Eye

width and height are bounded by a mask, and any violation of the mask

boundaries can indicate non-compliance12. An example of eye diagram together with eye mask (shown in blue) is provided by Figure 3. It displays signal captured (at the receiver end) for a 1.5 Gb/s Serial ATA (SATA) bus.

Figure

3 depicts a sufficiently open eye. When the eye is closed, there are

various techniques such as pre-emphasis or equalization13 which may be applied to open the eye.

Pseudo-random binary sequence (PRBS) patterns14

are frequently used as stimulus (to the channel) to generate eye

contours. PRBS is a data pattern that attempts to replicate truly

random data yet it is completely deterministic. PRBS patterns have

length of [(2^N)-1], such as [(2^7) – 1] = 127 bits.

Each

signaling standard (e.g. SATA, PCI Express, XAUI, HDMI, etc.) specifies

how to capture data for eye measurements (including clock recovery

method) and the masks that ascertain compliance or non-compliance12.

Many high-speed serial links incorporate 8b/10b encoding12 to guarantee minimum transition of data (to aid receiver recover clock) and apply scrambler to reduce EMI.

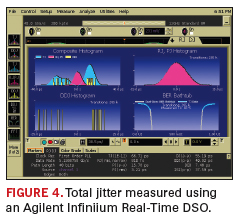

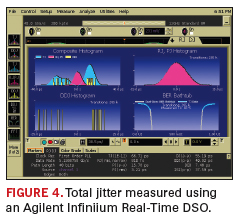

Certain

test equipment such as Agilent Infiniium DSO81204A (12 GHz 40 GSa/s)

allow jitter measurements on ultra-fast serial signals and can display

total jitter, random jitter, deterministic jitter, data-dependent

jitter, as well as pattern and periodic jitter. An example is

illustrated by Figure 4, which decomposes jitter into

subcomponents to facilitate debugging. Figure 4 also displays histogram

and bit error rate (BER) bathtub curves. Such displays are useful for

quickly correlating15 multiple answers, detecting Intersysmbol interference (ISI), and knowing whether the device meets the standard.

ISI can be caused by transmission line losses (which degrade signal rise time) and lead to degradation of the eye diagram13. BER is an important metric16

for quantifying the performance of high-speed serial architectures. The

BER and jitter analyses/testing have become a necessity to assure

performance requirements for high-speed serial links, particularly due

to the increasing data speeds. PCD&F

Dr. Abe (Abbas) Riazi is a senior staff electronic scientist with ServerWorks (a Broadcom Company) in Santa Clara, CA.

ACKNOWLEDGEMENTS

Special thanks to Richard Kuo for reviewing the manuscript and providing valuable comments.

REFERENCES

1. Greg Edlund, ”Timing Analysis and Simulation for Signal Integrity Engineers”, Prentice Hall, 2007, P.2, PP. 13-14.

2. Jim Peterson, “Timing Numbers from ICX - What Do We Do With Them?”

Mentor Graphics International User Conference May 2-5, 2006.

3. Abe Riazi, “ Timing Analysis Principles for Digital PCBs, Part 2”, Printed Circuit Design & Manufacture, June 2006, PP. 20-21.

4. Abe Riazi, “ Timing Analysis Principles for Digital PCBs, Part 3”, Printed Circuit Design & Manufacture, August 2006, PP. 16-17.

5. Tod Westerhoff, “Closing the loop between timing analysis and signal integrity“, Cadence Online Seminar, August 28, 2000.

6. “DDR2 Design Guide For Two-DIMM Systems” Micron Technical Note, TN-47-01.

7. Tom Granberg, “Handbook of Digital Techniques for High-Speed Design“, Prentice Hall, 2004“ PP. 583-586.

8. Stephen H. Hall, Garrett W. Hall, James A. McCall, “High-Speed

Digital Design, A Handbook of Interconnect Theory and Design Practices,

“John Wiley and Sons Inc., 2000, PP. 186-190.

9. Bill Hargin, “Managing Signal Quality”, Xcell Journal, Second Quarter, 2005.

10. Abe Riazi, “Signal Quality Assessment”, Printed Circuit Design & Manufacture, June 2007. PP. 16-17

11. Roy G. Leventhal and Lynne Green, “Semiconductor Modeling For

Simulating Signal, Power, and Electromagnetic Integrity”, Springer,

2006, P. 30.

12. “The Basics of Serial Data Compliance and Validation Measurements”, Tektronix.

13. Eric Bogatin, Signal Integrity – Simplified, Prentice Hall, 2004, PP. 333-335, PP. 398-399.

14. Min Wang, Henri Maramis, Donald Telian, Kevin Chung “New Techniques

for Designing and Analyzing Multi-GigaHertz Serial Links”, DesignConn

2005.

15. “Agilent 86100C Infiniium DCA-J, the fastest way to the right answer”, Agilent Technologies.

16. Mike P. Li, and Dennis Petrich, “Characterization and Production

Testing At 3.2-5.0 GB/s for PCI Express II and FB DIMM”, 2006 Wavecrest

Corp.