Inexpensive, high-performance packages can be fabricated by

laminating thin, flexible, mechanical devices into conventional

multilayer circuit boards.

The packaging industry and the research

community are developing new techniques for keeping up the race for

increased functionality in smaller packages, and 3D integration is a

good option in this respect. One 3D approach, the integration of active

circuits inside the innerlayers on a multilayer rigid or flexible

printed circuit board (FPCB), allows for a high degree of

miniaturization. Recently, an ultra-thin-chip package (UTCP) technology

was worked out, which allows embedding thin dies inside these flexible

circuits.

Today’s rapid succession of new cell phone

iterations clearly illustrates the mission of the electronics industry

to increase functions while decreasing the size and weight of

electronic products. The semiconductor industry meets this target by

miniaturizing transistors to integrate more of these building blocks

onto the same silicon area. The packaging industry, on the other hand,

is challenged to integrate and to shrink the IC and system’s package.

There

are a number of packaging technologies that have been developed and

deployed to reduce the footprint of IC and system’s packages: flip chip

bonding instead of wire bonding; chip-scale packages; and

system-on-chip and system-in-package technology.

Using the Third Dimension

For

some applications, the technologies described above are still not

sufficient to meet the product requirements. For example, think of

third-generation PDAs with telephones, internet, GSM and photographic

capabilities. To increase capacity and/or functionality in the same

volume, 3D packaging methods are required.

There are different

approaches for 3D modules. Multiple dies can be stacked inside a

package. Aside from space savings, die stacking also results in better

electrical performance of the device, since the shorter routing of

interconnections between circuits results in faster signal propagation

and reduction in noise and cross-talk. The stacked die may be

interconnected using wire bonding alone or by a combination of wire

bonding and flip chip assembly. Alternatively, through-silicon vias

(TSV) can be used to interconnect the stacked dies, allowing for

further miniaturization and increased performance.

A second 3D

approach is the use of stacked packages. In this case, the 3D stack

consists of subunits that are assembled after package level burn-in and

test. The advantages offered by the package-on-package (PoP)

architectures include memory flexibility and easy testing compared to

application specific integrated circuit (ASIC) and memory die stacking,

as well as the ability to mix and match devices from multiple vendors.

A

third approach for stacking active devices is the technique of folding

stacked dies to eliminate the need for spacers between them. This

process is referred to as “folded/stacked” technology. The dies are

produced side-by-side and then folded over so that the bond pads are

independent of each other. A relieving layer is placed between the

chips to alleviate thermo-mechanical stresses.

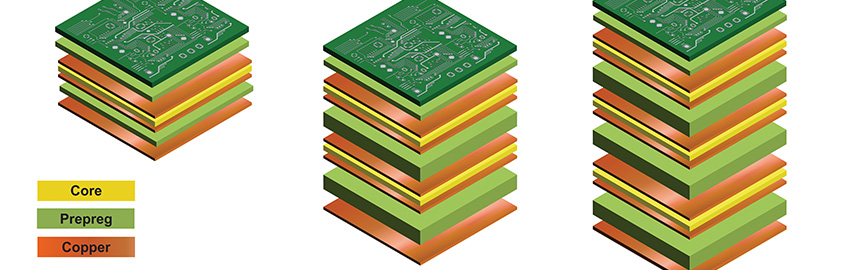

Finally, the 3D

approach with the highest level of miniaturization is the integration

of ICs inside circuit boards. The assembled packages, with active

circuitry, are thus removed from the outer layers of the substrates

and, together with passive components, are incorporated inside the

circuit board. The complete product or system, including numerous

passive and active components, can then be integrated inside the

motherboard, producing a System-In-Board (SIB) product. Such modules

allow assembly of surface mount devices on the bottom and top surface

and are typically used as motherboards for the rest of the components.

Some

technologies are already developed for integrating bare dies in the

innerlayers of multilayer substrates. Examples include the

Chip-in-Polymer technology (CiP), the chip-in-substrate package (CiSP)

and the Integrated Module Board technology from Imbera Electronics.

These above-mentioned technologies integrate the bare dies directly

inside the substrates. Possible hurdles include testing of the dies

before embedding (Known-Good-Die problem), necessary precise placement

of the bare die and the need for a very fine pitch PCB or FPCB,

compatible with the pad pitch of the embedded chip.

Recently,

Belgian researchers from IMEC and the Ghent University developed an

alternative approach for integrating ICs in PCBs and FPCBs: the

ultra-thin-chip package (UTCP) technology, which permits testing of the

chip before embedding and provides a contact fan out with a more

relaxed pitch. This eliminates the need for precise placement and

ultra-high-density PCBs.

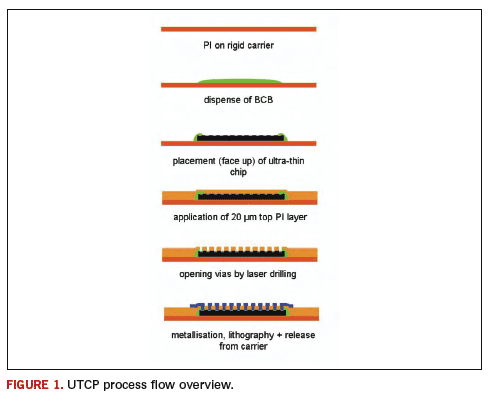

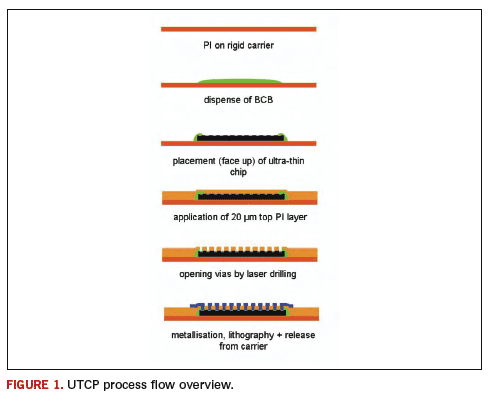

UTCP Process Flow

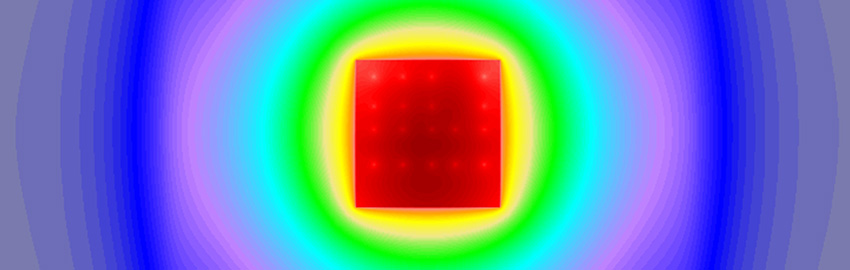

UTCP technology

is a polyimide-based embedding technology for integrating very thin

silicon chips in flexible substrates. Dies with thicknesses down to

15μm can be embedded between two 20-μm-thin, spin-on polyimide layers,

resulting in a package with a total thickness of only 50 μm to 60 μm.

Thanks to the very low thickness of the chip, the polyimide layers and

the metal, the whole package is bendable.

The base substrate

is a 20-μm-thick polyimide layer, spin-coated on a rigid glass carrier.

For the fixation and the placement of the chips on the polyimide layer,

a benzocyclobutene of about 5 μm is used as adhesive. By placing chips

properly in a dispensed benzocyclobutene, void-free bonds can be

obtained. After the cure of the benzocyclobutene at 350° C, the chips

are fixed on the polyimide layer. A covering polyimide layer is

spin-coated on the fixed die with a layer thickness of about 20 μm.

This allows the chip to be embedded between the two polyimide layers.

For interconnecting the chip, contact openings to the bumps of the

chips are laser drilled. Next, a top metal layer of 1 μm TiW/Cu is

sputtered and photolithographically patterned, metallizing the vias to

the chip and providing a fan out to the contacts of the chips. If

needed, the sputtered top metal layer can also be enforced by

electroplating. Finally, after processing and functionality testing of

the integrated devices, the whole package can easily be released from

its rigid carrier. The process flow can be seen in

FIGURE 1.

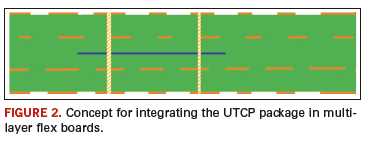

Embedding for Flexible Circuits

Flexible

circuit boards can be used to integrate electronics into clothing or

onto curved surfaces such as machine parts. On typical flex substrates,

only pure electronic assembly is performed on the flip chip components.

Embedding of passive or active components in flexible printed circuits

is not state of the art. The presence of relatively large rigid

components, only on the front and backside of the flex laminate, is an

important factor limiting not only the miniaturization, but also the

mechanical flexibility of the circuits.

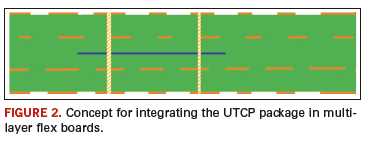

Based on the

above-mentioned UTCP approach, a technology was worked out for the 3D

integration of active devices inside the innerlayers of commercial

multilayer flexible circuit boards (

FIGURE 2). The UTCP packages

serve as interposers: ultra-thin active devices are first integrated as

UTCP, which in turn, is embedded inside a standard multilayer flex

circuit.

A suitable process flow to

integrate small UTCP packages inside large flex laminates has been

successfully established at ACB, a Belgian flex manufacturer. UTCP

packages are aligned and fixed (by heat tack) on a patterned inner

layer of the multilayer substrate, and connection between package and

wiring of the PCB or FPCB is achieved by through-hole interconnects.

This

embedding concept was first demonstrated with UTCP test packages,

indicating that a 3.5 μm metal thickness on the UTCP package is

sufficient to ensure good interconnects and that an ENIG metal finish

on the UTCP samples will not affect the through-hole plating quality.

Daisy chain interconnects between integrated dummy packages and the

FPCB were characterized and monitored during reliability

investigations. High temperature storage at 150° C (up to 1000 h), hot

humidity storage at 85° C/85 relative humidity (up to 1000 h) and

thermal cycling between -40° C and +125° C (up to 1000 cycles) did not

introduce any failure at the interconnects. The integration process

also does not affect the values of the 4PT via resistance of the

interconnects on the UTCP package.

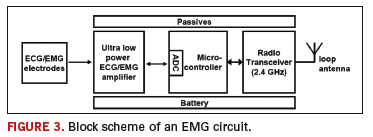

Technology Demonstration: Functional ECG

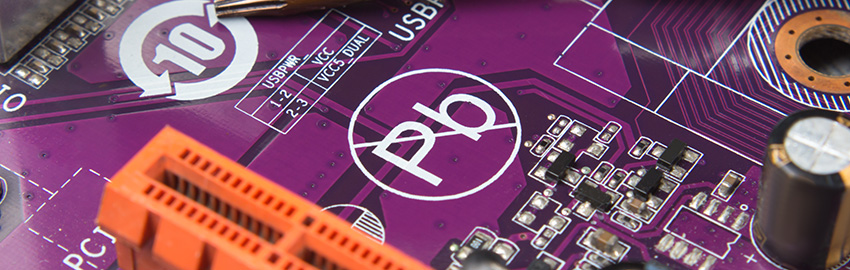

Wearable

monitoring systems for health or sport applications often make use of

flexible circuit boards. In this way, they can unobtrusively be

integrated into clothing or be worn in the form of a ‘band-aid’. An

important factor limiting miniaturization and flexibility is typically

the presence of relatively large rigid components. For this reason, the

UTCP technology for embedding active circuitry into an FPCB is ideally

suited for these systems.

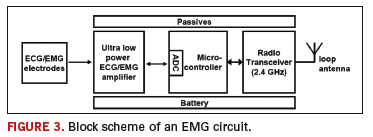

A prototype ECG/EMG wireless monitoring system (

FIGURE 3)

was realized using the above-described technology. The prototype

measures the heart rate (electrocardiogram or ECG) and muscle activity

(electromyogram or EMG). It consists of three integrated circuits: an

ultra-lowpower ECG/EMG amplifier circuit, a commercial TI

microcontroller with embedded analog-to-digital converter (ADC) and a

Nordic 2.4 GHz low-power radio transceiver. Additionally, some

supporting passives, a battery, a loop antenna and some electrodes are

included.

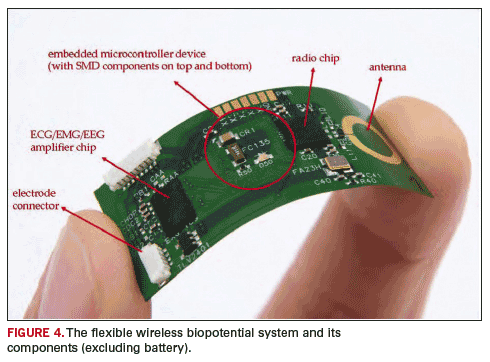

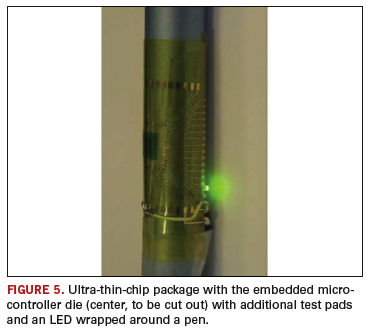

The microcontroller and ADC

circuit were embedded inside an FPCB. First, the individual chip was

thinned down, starting from the initial die thickness of 300 μm to 25

μm, using a proprietary-developed individual chip thinning process.

Secondly, these very thin, functional microcontroller devices were

embedded as an ultra-thin-chip package. The UTCP-packaged

microcontroller could easily be tested after assembly but before

release from its carrier. After testing the UTCP-packaged

microcontrollers, they were cut out from the glass substrates,

resulting in ± 1 cm² x 1 cm², square UTCP packages. Next, the

UTCP-packaged microcontrollers were integrated in the innerlayers of

the multilayer flex substrates. Finally, components were assembled on

both sides of the flex substrates: SMT components, the IMEC

biopotential ASIC and the Nordic radio. These actives were wire bonded

on the substrates (Chip-On-Flex, [COF]), after the SMT components were

assembled.

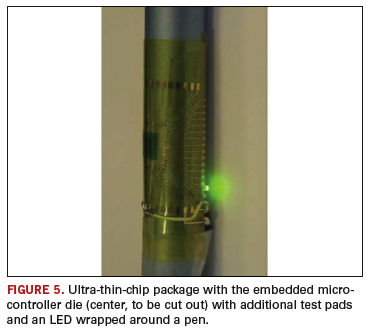

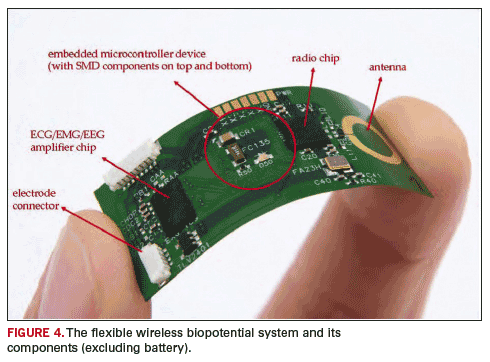

The wireless ECG/EMG biopotential prototype (

FIGURE 4) with UTCP-packaged and FPCB-embedded microcontroller (

FIGURE 5) proved to be completely functional and able to monitor ECG and EMG signals.

Conclusion

The

ultra-thin-chip package (UTCP) technology offers the possibility to

integrate functional devices inside flexible multilayer circuit boards.

These UTCP interposers provide a contact fan out with more relaxed

pitches, allowing for easy testing before integration. Moreover, this

fan out eliminates the need for precise placement and

ultra-high-density printed circuit boards. The thin, mechanical

flexible devices can be laminated inside the adhesive innerlayers of

conventional low-cost multilayer substrates, using only standard

production processes. PCD&F

ACKNOWLEDGEMENTS

This

research was done in the framework of the FP6 project SHIFT. This

publication is intended to report the outcome of the research and the

capabilities of the technology developed in the framework of this

project.

Els Parton is a scientific editor responsible

for authoring and editing IMEC’s company technical documents and

publications;

This email address is being protected from spambots. You need JavaScript enabled to view it..

Wim Christiaens is a technology developer at Ghent University.

Jan Vanfleteren is a senior engineer with the IMEC-CMST group and a part time professor at the Ghent University.