-

Maximizing Yields with Minimal Iterations

DfM practices for preventing common fab and assembly defects.

READ MORE... -

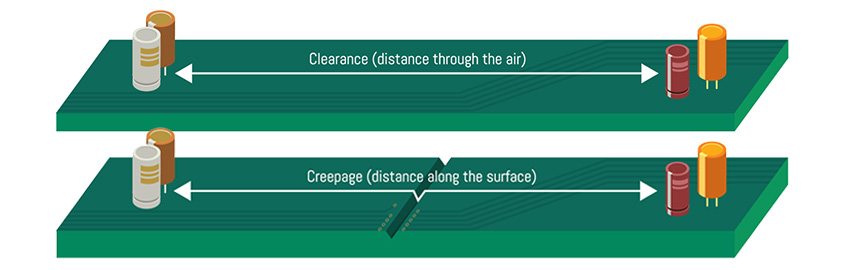

Clearance and Creepage in PCB Design

An overview of standards and guidelines for high-voltage applications.

READ MORE... -

Addressing the Global Talent Shortage

Changing dynamics in the workforce are driving the need for an intuitive user experience. Are the tools up to the task?

READ MORE... -

So You’re a Designer. Now What?

PCB designers can have many different career pathways.

READ MORE... -

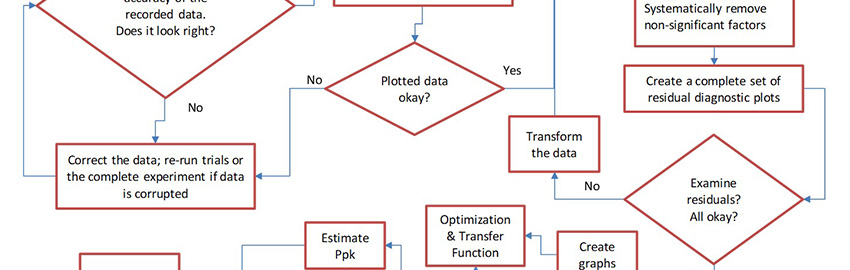

How to Run a Design of Experiments

A review of the six fundamental steps behind scientific process development.

READ MORE...

Homepage Slideshow

Maximizing Yields with Minimal Iterations

DfM practices for preventing common fab and assembly defects.

Clearance and Creepage in PCB Design

An overview of standards and guidelines for high-voltage applications.

Addressing the Global Talent Shortage

Changing dynamics in the workforce are driving the need for an intuitive user experience. Are the tools up to the task?

So You’re a Designer. Now What?

PCB designers can have many different career pathways.

How to Run a Design of Experiments

A review of the six fundamental steps behind scientific process development.