A New Covid Surge in Taiwan?

Taiwan is the benchmark for controlling the spread of Covid-19 and minimizing the infection rate throughout the country with very few deaths.

The electronics industry in Taiwan grew throughout the pandemic. Unfortunately, over the past few weeks an increase in cases was reported. The numbers are still small but growing, and Taiwan is scrambling to secure enough vaccines for its population.

The electronics industry is performing well. The following graph shows monthly shipments for the Taiwanese PCB industry. The blue line represents rigid board circuits, and the pink line represents flexible circuits:

Figure 1. Monthly PCB shipments in Taiwan

Rigid circuit board shipments remained flat over the last 10 months with an exception during February (seasonal drop due to the lunar vacation.) The PCB manufacturers are concerned with a bottle neck in the material supply chain that is affecting production capacities. If the supply line replenishment smooths out, more circuit boards will ship. Most manufacturers are very confident with their projections because of strong demand for notebook and tablet PCs.

The flexible circuits segment tends to be seasonal depending on Apple’s iPhone sales. Historically, sales peak during the fourth quarter from Christmas demand. Monthly shipments of flexible circuits continue the same trend as last year with digit growth. Apple reached the lead position for smartphone sales during the fourth quarter. If their popularity continues, shipments for flexible circuity will grow for the rest of the year.

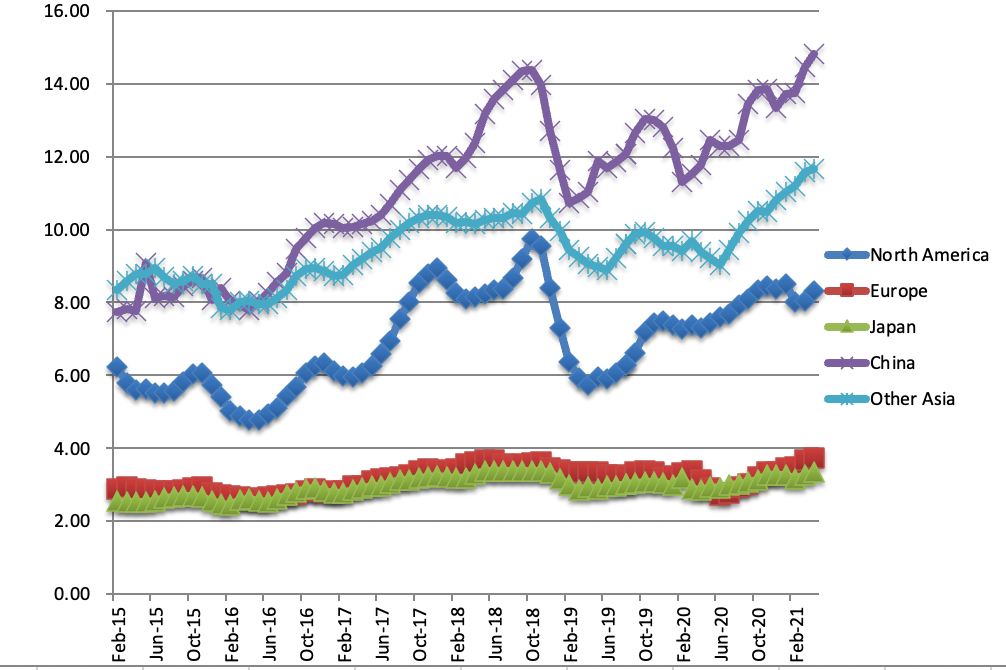

It’s no secret – there is a semiconductor shortage throughout the world, and is hitting the automobile industry the hardest. Many automobile manufacturers temporarily reduced or stopped production. Figure 2 shows the global shipment of the semiconductors. China leads the way but other Asian countries are posting strong results over the last 10 months (Taiwan is one of the major contributors). Demand outweighs supply by a long shot; this imbalance will remain for the next few quarters. The Taiwanese semiconductor manufacturers will enjoy business feast for a while!

Figure 2. Monthly semiconductor shipments by area.

The only fly in the ointment for Taiwan and other Asian countries is the increase in Covid-19 cases. This should take care of itself within a couple of months with the supply of Vvccines earmarked for most of these countries. I am confident the pandemic with be behind us and business will continue to grow.

Dominique K. Numakura, This email address is being protected from spambots. You need JavaScript enabled to view it.

DKN Research Newsletter #2116, June 27th, 2021 (English Edition) (Micro Electronics & Packaging)

*To view the newsletter archives, click here.

Headlines of the Week

1. NIMS (Major R&D organization in Japan) developed an all-printable process to generate TFT devices on various substrates including plastic films silicon wafer because of low sintering temperature (90C).

2. Alps Alpine (Major module manufacturer in Japan) introduced an obstacle detector module for next-generation electric carts. A low-cost active IR stereo camera module measures the distance to the objects.

3. TPCA (Taiwan Printed Circuit Association) announced May shipment figures for PCBs in Taiwan. Revenue was NT$58.8 billion, a 1.1% increase from the previous month and a 16.8% increase from the same month of the previous year.

4. Panasonic (Major electronics company in Japan) commercialized a new copper laminate series “R-1515V” for next-generation semiconductor packaging. It provides high reliability and excellent dimensional stability.

5. Toshiba (Major electric & electronics company in Japan) developed a new structure for SiC-based MOSFET devices. The new structure is higher reliability and lower power loss at higher temperature (over 175C).

6. Renesas Electronics (Major semiconductor manufacturer in Japan) said the facility of Building #3 at its Naka Plant is 100% recovered from the fire in March. Production has started. 100% operation will be by the end of July.

7. Osaka University (Japan) developed a new bonding process for Teflon resins introducing a new surface treatment called “Thermo Assyst Plasma Treatment,” instead of the sodium-based chemical process.

8. Panasonic (Major electronics company in Japan) opened a customer service laboratory “Network Connect Lab” in Yokohama for 5G collaboration with customers.

9. Toshiba Device & Storage (Device manufacturer in Japan) demonstrated a new connection system for prototype modules of IT systems. It does not need soldering..

10. Tohoku University (Japan) codeveloped a method to analyze the chemical process of de-oxidation in the cathodes of lithium-ion batteries. The method is applicable for various secondary batteries.