At Productronica, the Machines Did the Talking

Two years ago, it was all about the machines. This time, it was about how those machines will communicate.

Messe International Fairgrounds in Munich, home to Productronica, is the largest electronics manufacturing trade show outside Asia, with more than 44,000 visitors attending the four-day event.

Colocated with SemiCon Europe, the show fills nearly eight halls, each the size of an airplane hangar. All the major players in every aspect of electronics assembly production attend, as well as hundreds of smaller companies.

As Industry 4.0 continues its ramp, a distinct emphasis on machine-to-machine and factory-wide communication has emerged. Many equipment vendors, especially the larger ones, emphasized their ties to one or more of the various communication protocols under development.

The Hermes Initiative, an undertaking led by ASM and backed by many European OEMs, was released at the show and will be available on machines in the next few months. Hermes adds intelligence to conveyors and simpler equipment. Also during the show, IPC announced that its consortium for factory data communication, CFX, has assumed control of an Aegis-donated protocol. IPC’s membership will vote on the 75-plus-page open-source standard this spring. CFX targets messages between machines and MES/ERP/MoM programs, as does Mentor’s proprietary OML, which remains the only program actually in use. The major Japanese OEMs have signed on to support a common JARA M2M interface, which may or may not eventually be Hermes. Others seem set on leveraging the semiconductor industry’s SECS/GEM standard. And several machine-to-user protocols, including ones developed by Asys and ASM, were prominent.

The Asys AIV has much-improved mobility and obstruction sensing, and now voice as well (“please step aside”).

Automotive vehicle sales may be slowing, but thanks to ever-higher electronics content, the emphasis by many OEMs remains on the sector. Another trend in equipment is the feature/speed tradeoff. Today, it seems the pendulum has swung back to speed, especially with placement machines.

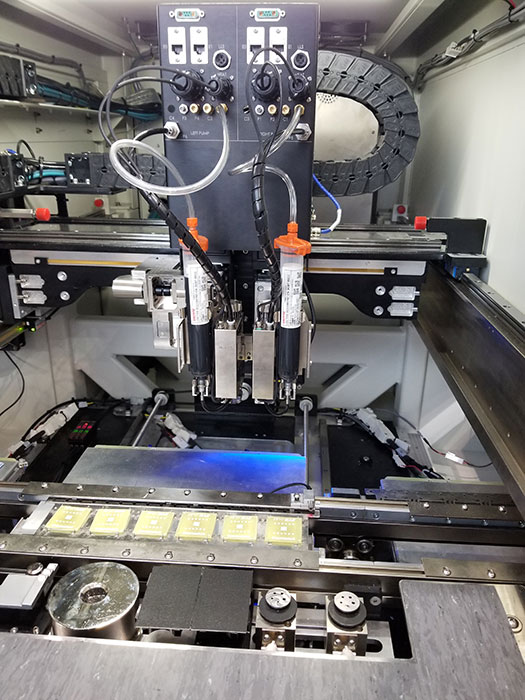

Among the print and dispense developments was the ITW EAE NuJet Dynamic Dual Head, which is featured on its Prodigy dispenser. The dual-heads, each pneumatic jet piezo-driven styled, are situated just 1" apart for simultaneous dispensing. The vision system maintains accuracy even if parts are skewed on the x/y plane or are on different z heights. The MPM Edison 15/15 is so-named for its 15µm accuracy at Six Sigma and 15 sec. cycle time, including overhead functions. Asys added a jet valve for glue or paste dispensing to its Ekra iPag.

ITW EAE’s Prodigy dual-head dispenser.

The Nordson Asymtek Vantage dispenser is a new high-volume platform for advanced packages and 3D die stacks. It features a heavier, more rigid frame. The linear drive system is dual-lane and has easy-to-customize software. The company also showed the Helios bulk dispenser for two-component mixtures such as thermal interface materials. Yamaha entered molded interconnect device production with its 3D MID machine. Based on the S20 placement platform, it reportedly distributes adhesive or solder and mounts components anywhere on 3D substrates.

The Atom 3 and Atom 4 represent Europlacer’s move into the high-speed placement market. The Atom 3 has one flexible and two high-speed heads, while the Atom 4 is a four-head, four gantry system capable of 100,000cph. The new software is backwards compatible with the iineo generation, and the feeders are compatible as well.

With the Atom 4, Europlacer joined the ranks of high-speed placement OEMs.

Fuji showed its SFab-D (D stands for double-sided) odd-form placement machine. It handles parts either loose or on tape or in trays. Its new NXT III M6L targets low-impact assembly on thin boards. The NXT III M3IIIC features V12D heads capable of 120,000cph. Universal Instruments is considering more high-end semiconductor packaging assembly, which would put it head-to-head with KNS. Yamaha’s Advanced Robotics Automation platform uses Orbit SCARA and Cartesian robots to mount a host of odd-shaped parts and connectors.

New this year was NeoDen, a UK-based company with a lab-sized placement capable of placing up to 5,000cph when the vision system is on (10,000cph when off), and capable of metric 0201 up to 35 x 35mm BGAs and QFNs. Some 66 units have been sold to date. Mimot’s MIT4 Double Wing++ has extendable feeder capacity on the left and right sides of the machine, raising the number of slots to 168 from 84.

The new BTU Pyramax Vacuum oven is designed for lower voiding. It features 10 top and bottom closed-loop heating zones. Trials will start in 2018. SMT showed the new QuattroPeak R360 convention reflow oven, which has a vacuum function and built-in troubleshooting guide. EFD previewed its patented OvenSentinel, a continuous process monitor for ovens with a dashboard that is completely customizable. It captures more than 40 data points and works with the same subnet as a company’s plant, either internally or in the cloud. The built-in AI pulls out trends and even dips into other databases (e.g., the MES) to pull data from AOI, x-ray and final test to look for variations and build correlations. It is due out in the first quarter of next year.

BTU’s Pyramax was one of a slate of new vacuum reflow ovens.

Robots were more common but less promoted than in 2015. Asys, Zevatron, Essert, Fuji, Staubli, Yamaha, Bauman, Igus, Engmatec and Automatrix were among the vendors showing robotic advancements.

Inspection equipment was everywhere. More than 40 companies offered surface inspection; 28 showed AOI, and another 20 had x-ray equipment.

Mirtec reports more demand for wafer-level package inspection. Light shined on bare die using standard moiré tends to reflect. The MV-3 Omni desktop AOI automatically inspects for defects both pre- and post-reflow. Designed to capture inline capability for an offline price, it uses a blue LED projection moiré to characterize those highly reflective devices and solder joints that standard moiré or laser cannot handle.

Viscom has extended its S3088 Ultra with the Chrome configuration, one of three standard configurations the 3D AOI comes in. The previously available entry-level Blue line is aimed at companies primarily using 2D capability; the top of the line Gold model is a high-resolution, high-speed 3D inspection machine. Chrome targets users who desire speed along with 3D quality. The new X8068 SL inline x-ray features automatic loading and targets larger boards, power electronics and “massive” components.

Yxlon extended its x-ray systems to fit the end-user application. The Cheetah EVO SMT is for manual or automatic applications, and takes advantage of dynamic image enhancing filters. The Cheetah EVO Semi targets the semiconductor industry, offering void measurement and on-the-fly inspection. The Cheetah EVO Plus is a microCT system aimed at the lab.

Saki continues to report strides in the automotive sector. The new 3D platform has a beefed-up aluminum frame to reduce vibration, and linear encoders with scalable accuracy to 0.1µm for better control of the head position. The standard 12µm resolution head can be adjusted to optional 7µm resolution by swapping the lens. The system is 180% faster than the previous model. A user-friendly Wizard performs auto-programming based on IPC standards. The new 3Si-LS2 SPI is built on the same platform as the AOI, applies scalable resolution, and has an accuracy of 3µm at 3 Sigma.

ALeader has come a long way since I first saw them in China more than a decade ago. The new ALD8700S 3D AOI platform now measures height. Using its new interface, users can apply Gerber files to locate pads and make go/no-go decisions based on built-in IPC Class 1, 2 or 3 specifications. It looks for component shift, coplanarity, tombstones, shorts, and lifted lands using a single camera and digital projection system.

Nordson YesTech has a unique configuration for its FX-940. The 3D AOI has a new projection system with a projector and multiple cameras, and software that reduces reflections and shadowing to improve metrology. It is being shown integrated with the Nordson Asymtek conformal coater, featuring a UV curing system underneath as part of a dispense-cure-inspection configuration. The FX-942 double-sided through-hole inspection system introduced earlier this year has two heads, one on each side, and UV light for conformal coating coverage and thickness.

Newly acquired by Mycronic, Vi Tech’s PIE SPI has a touchscreen user interface that eliminates the mouse and keyboard. SIGMA software correlates SPI and AOI data, and is said to review manufacturing processes in 3D and in real time. A color code system indicates the process is nearing the end of its tolerance range. It ties into the Mycronic printer and pick-and-place. The related 5K3D AOI shows real metrology in 3D.

Parmi showed Xceed, its hybrid SPI/AOI, available for inline or offline usage. While the name is the same as the AOI model released two years ago – which Parmi says it may change – this version performs bottom-side inspection. Another feature is a laser that looks inside holes for press-fit connectors, for instance, and can measure dimensions.

New to the scene is Ash out of Ireland. The microscope manufacturer is showing its competitively priced Omni line, which can tilt the board under inspection, digitally measure lead-to-lead distance, and imports DfX or Gerber and uses those files as a digital overlay on the screen to compare with the parts on the board.

Hailing from Great Britain, LRD Electric launched four machines in the past year: two benchtop AOI and two inline systems. The entry-level Kite line scan model has a top-down camera and performs first article or fully automated inspection on parts down to 0402. Merlin, the other benchtop model, offers a 5Mp camera with a telecentric lens, for inspecting parts down to 01005 and 0.3mm pitch. Osprey is a standalone inline version of Kite, a linescan camera with a telephoto lens, while Falcon is the higher resolution inline model. All are competitively priced.

In addition to its IPC CFX announcement, Aegis Software launched its new version of FactoryLogix MES 2017.1, which facilitates the transfer of production processes and documentation from plant to plant, and creates workflows and instructions on the fly. The Asys booth was heavy on material logistics software and tools. Its AIV (Autonomous Indoor Vehicle) can bring reels, Waffle packs and more to the placement line. It works in concert with the ToTech component storage cabinets, and can navigate a several-kilograms load between facilities. Besides the mobility improvements, Asys has added a voice to the AIV that alerts people to its presence.

We didn’t spend much time on cleaners. Teknek had an inline board cleaner, SMT 2017 (20.20), a very narrow width roller-and-adhesive-based system. ITW EAE showed its latest Aquastorm, a small-sized inline aqueous and chemistry cleaner. PBT’s HyperSwash is a fully automatic spray-in-air closed-loop zero drain system with multi-level cleaning baskets.

Labels aren’t the focal point of big shows, but Identco has made a leap forward with its printable 2 x 2mm micro-labels.

Productronica is primarily an exhibition for showcasing electronics assembly equipment and materials, but in a few cases those manning booths are producers instead.

More than a dozen EMS companies exhibited this year. All were smaller players, with sales ranging from a few million to about $150 million. Unlike two years ago, when many EMSs were clustered by country, Estonia was the only nation to sponsor a common booth this year. The other participating EMSs were generally located nearby, helping to fill out the otherwise shrinking bare board fabrication exhibition space. The award for uniqueness goes to Selteka, a Lithuanian EMS that has designed and built an inline-capable automatic programming, calibration and functional tester and AOI. The firm uses it on one of its four SMT lines and says it plans to fully implement the new machine across all its lines. It doesn’t have a name but is being commercialized and was shown at Productronica.

Fabrication a Fading Fashion

The emphasis on fabrication lessens by the year at Productronica. Fifteen years ago, the fab side occupied more than two full halls at the Munich trade show. This year, there were perhaps fewer than 40 standalone exhibiting companies, even including some vendors that piled into their local distributors’ booths. The big Japanese and Taiwanese players were not present. Insofar as fabrication is concerned, Productronica has turned into a regional show.

And no wonder. Most of the equipment and materials shown have been around for some time. On a happy note, many of the machines bore SOLD signs, and talk in the booths rarely returned to economic concerns.

Perhaps the largest single company booth belonged to Orbotech. Among the many systems shown was the new Ultra Dimension PCB AOI, which integrates leading pattern inspection, laser via inspection, remote multi-image verification (RMIV) and 2D metrology. It uses varied light settings and three different types of images to improve detection capabilities, reduce false alarms and decrease inspection setup time. It is also said to eliminate the need to use inspection masks. The system automatically measures both top and bottom conductor widths for lines and pads of a wide variety of shapes, enabling higher accuracy and impedance control necessary for SLP/mSAP, as well as advanced HDI applications.

LPKF had its ProtoLaser R, which was actually released in late 2016 but not promoted since. The ultra-short pulse (USP) laser-based machine has a laser diameter of 15µm and performs cold ablation on materials as thin as 0.2mm. It also had the MicroLine 5000 and the MicroLine 2820P, a pair of depaneling systems introduced at IPC Apex in February.

Schmid demonstrated its new InfinityLine V+ develop/etch/strip line for contact-free vertical processing of thin PCBs. It uses transport clamping frames for secure, contact-free transport at up to four panels per minute. The system reportedly reduces chemical drag-in and drag-out, is compliant with energy efficiency standards, and offers low wear and longer service. A new drive system prevents deposition of particles on the product.

Yamuchi showed the YOM series of press pad coverlays for solder mask. The reusable pads consist of a glass cloth injected with a high-temperature-resistant rubber. The encapsulated air adds sponginess to the otherwise rigid material. The YOM-Flex version handles up to 70 cycles before replacement.

The Hakuto Mach 630NP dry-film automated cut-sheet laminator received a facelift in the past year. The lamination roll now can be easily exchanged in a short (roughly 5 min.) cycle. Pressurization uniformity has been improved as well.

Another Hakuto product on display, albeit under the Advanced Engineering nameplate, was a fully automatic high-volume direct imager, the HAP8210A. Powered by four multi-wavelength long-life LEDs (365, 380, 395 and 405nm), it comes with four, six or eight heads. It images line and spaces down to 25µm, with a registration accuracy of 15µm, and repeatability of registration of 10µm at 3 Sigma. The reported throughput is up to 200 double-sided panels/hr.

Kuttler’s P650 peeler has a novel coating of the sword and improved ionization. Servomotors now run the drives, and the extraction roller has a constant torque. The software and control system have been fully redesigned by Kuttler as well. The Agiline robotic handler is ESD-proof, thanks to a carbide material. It can be configured for horizontal or vertical processing.

Visper of Japan had the Visper 7 series automatic double-sided inspection machine. The system combines double-sided simultaneous imaging and vertical transport. Resolution is reportedly down to 18µm for a 2" x 2" to 9.875" to 14.125" board. The Visper 8 has similar capability for horizontally processing flex boards.

Risho had the AD-7208 aluminum-based copper-clad laminate PCB material and CD-7208 resin-coated copper foil, both with a special resin with a thermal conductivity of 8W/mK. Designed for high-power LEDs and power modules, they feature a Tg of 270°C (DMA), and CTEs of 9 and 22 ppm/°C, respectively.

From Hong Kong, the Boffotto P15V plasma processing system performs surface cleaning for drilled and routed printed circuit and HDI boards, and surface roughening and cleaning.

Boffotto’s P15V plasma processing system.

Limata showed the X2000 and X3000 LDI, which made their debuts last year. Designed for high-volume laser-direct imaging of outer- and innerlayers and solder mask layers, the X3000 is capable of 2 mil lines and spaces, handles imaging sizes up to 96" x 48", and has an optional vision system. A “double-drawer” system speeds throughput.

Firms like Microline and CLTech (the ex Circuit Line e Mania Tecnologie Italia) had their electrical testers present. They are newer models, but not new. Likewise, PrintProcess, Manz, Lenz, Schmoll, Wise and others displayed mature machines. Cemco, for instance, had its Hole Blaster, which uses air knives to remove debris from holes and board surfaces. The machine debuted at least five years ago, however.

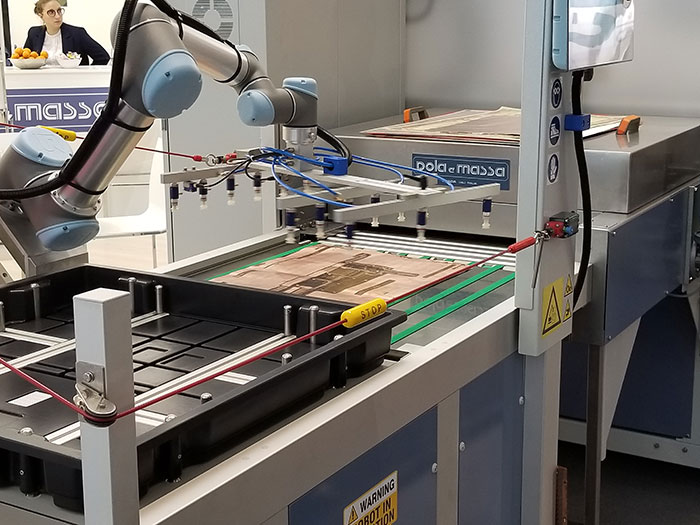

Unlike in the assembly halls, fab OEMs have not aggressively implemented robots. Most that did have robots on display also had them at the 2015 show. That said, watching Pola e Massa’s Heron 5 series loading boards is always neat. Same goes for the Kuttler Agiline robotic handler.

Pola e Massa’s robotic PCB loader.

Ed: Check out our Twitter feed at twitter.com/mikebuetow or our Facebook pages for additional photos and videos from Productronica.

is editor in chief of PCD&F/CIRCUITS ASSEMBLY; This email address is being protected from spambots. You need JavaScript enabled to view it..