Thermally Conductive Microwave Materials

Increasing the thermal conductivity of the base materials improves thermal management in RF designs.

Looking

at the thermal issues which are impacting microwave design in today’s

marketplace, we see several drivers that will continue to require

better and more effective thermal management in the near future. Some

of these factors are relevant to all electronics packaging, such as

increased watt density on smaller package footprints, but others are of

particular importance to the microwave and RF industries. Among the

more important considerations for the microwave engineer are:

- Power density (Watts/square inch of PCB area) continues to increase

- Packaging is getting smaller & hotter (inherently increasing watt density still more)

- Tower mounted & outdoor electronics increase environmental exposure while requiring higher reliability

- Complex waveforms decrease amplifier efficiency, resulting in more energy lost to heat

- Higher temperatures reduce component reliability

- Dielectric constant of many materials varies significantly with temperature

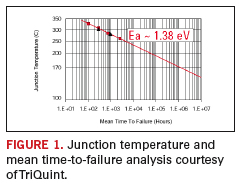

When

the heat generated by an active device mounted on a PCB cannot be

dissipated, then the temperature of the device rises. With all the

drivers pointing toward more power and smaller board surface area, the

watt density becomes such that temperatures can easily exceed the

qualificated temperature for many of the individual components. Since

reliability of components follows a first order Arrhenius equation, a

10ËšC increases in temperature doubles failure rate, so even 1ËšC

temperature increase matters. Figure 1 shows data

presented by Eli Reese of TriQuint, and presented at IWPC in November

2005, relating junction temperature to mean time-to-failure. The key to

reducing junction temperature is to increase the rate at which heat can

be removed from the device and from the working area of the PCB

immediately adjacent to the device.

The

cost of device failure can be significant since device failure accounts

for as much as 70 to 90% of equipment downtime, and in the case of

tower-mounted electronics, the cost can run several thousand dollars

for a simple repair that results in a short downtime. In bad weather

this can extend to a full day and cost as much as $25,000. Between

actual repair costs and potential lost revenue the implications of this

trend towards increased operating temperatures of PCBs is substantial.

The industry is looking seriously at solutions that can provide a

cost-effective way to mitigate the risk of failure.

Heat

is generated every time an active device is in operation. Heat itself

does not become a problem until there is an increase in temperature

above a critical point (typically 105 to 120ËšF). In simple terms, the

whole business of managing heat in a PCB assembly is about preventing

the junction temperature from getting high enough to “fry” the active

devices.

Heat is moved by one of three basic modes:

conduction, convection or radiation. In a PCB assembly all three are in

effect to one degree or another. The most effective is direct

conduction, where a warmer body is in direct contact with a cooler one,

and the heat moves from the hot to cold material (Figure 2).

The rate at which heat is carried from one to the other depends on the

thermal gradient, the coefficient of heat transfer of both materials,

the quality of the interface and to a lesser extent, the heat capacity

of the cooler body – that is its ability to absorb heat.

Convection

is the transfer of heat from a hot body to a cooler gas or liquid,

which carries the heat away. Convection may be aided by forcing the

cooling gas or liquid to flow past the warm body, removing the heat

more quickly. Radiation is the removal of heat from a body by the

emission of energy in the form of electromagnetic radiation, which may

be in the infrared (heat) or even visible (light) parts of the

spectrum, depending on the temperature of the radiating body.

Corollary

to consideration of the thermal conductivity (Tc) of laminate substrate

materials is also the fact that the heat transfer coefficient in the

perpendicular direction (through the PCB) is different from that in the

plane of the board. Unfortunately most modeling software assumes

isotropy, which may result in over or underestimation of the heat

removal.

Traditionally, a number of approaches have

been put forward to reduce temperature in PCBs by removal of heat from

active devices. The IWPC has been actively involved in assessment and

discussion of the various thermal management techniques, which include

the following:

- Laminated heavy metal backplanes (i.e. copper, aluminum, brass from 1 to 10 mm in thickness)

- Electrically and thermally conductive adhesion to plate (a good reference here is Ruwel)

- Thermal vias

- Thermal coins (a good example is the Merix E-Coin)

- Heat sinks, heat spreaders, heat risers (good references found at GrafTech)

- Thermally conductive adhesives, gap fillers, grease, etc.

- Active cooling – forced air, conditioned air

- Water cooled, vapor cooled, direct, indirect

While

all of these methods (note the predominance of the more efficient

conductive approach) are effective to varying degrees in the reduction

of junction temperatures, many of them have attributes that make them

less than ideal for use in microwave or RF circuit boards. Thermal vias

(a clusters of plated-through holes located beneath an active device)

are effective in removing heat because of the high thermal conductivity

of copper (370-400 W/m-K) but the plated through holes near the signal

traces can affect signal integrity, and a large number of plated

through holes can affect the mechanical strength of the PCB itself.

Heat

sinks and heat spreaders are heavy and expensive (a 3mm copper plate

can add as much as $25 to a single PCB) and devices such as thermal

coins that require cutouts result in increased fabrication complexity

and assembly costs. More sophisticated approaches such as forced

convection are costly, and may themselves be subject to risk of

electromechanical failure.

An attractive alternative

to total reliance on the traditional approaches of thermal management

is to build the underlying PCB with a dielectric material that is

inherently more thermally conductive. Conventional PCB materials having

a thermal conductivity of 0.2 to 0.25 W/m-K, and filled products range

from 0.4 to 0.6 W/m-K do not provide enough heat removal and heat

spreading capacity to do the job alone.

There are

new materials entering the market that have a 6.15 Dk and are suitable

for use as microwave substrate materials. These materials can provide

thermal conductivity (Tc) of 1.1 W/m-K perpendicular to the plane of

the board, and 1.4 W/m-K in-plane. This is more than double the best

thermal conductivity currently available in a standard microwave PCB

substrate materials, and high enough to allow designers to reduce

dependency on more costly approaches.

What benefit does increased thermal conductivity of microwave PCB substrates offer to the PCB designer?

- Component and solder joint reliability improvements would drive down warranty costs

- At constant heat rise, the improvement in heat transfer can be used to increase power handling by as much as 5-10%

Thermal stability of dielectric constant reduces dead bandwidth and increases phase stability over the temperature range reducing design limits and complexity

- It compliments all other alternative sources of thermal heat extraction at no additional cost

- Alternatively,

it potentially simplifies or lowers costs of other thermal solutions,

such as facilitating cast vs. machined heat sinks, and reduces in

copper plate thickness from 3mm to 1mm

The design objectives for the development of these thermally conductive materials included:

- Maintaining

the current material cost structure while improving dielectric loss

(loss tangent) and insertion loss to minimize heat generation in signal

transmission

- Increasing base laminate thermal conductivity (both perpendicular and in-plane) to reduce heat generation

- Maintaining laminate integrity in terms of key properties such as copper peel adhesion and low water absorption.

The

specific target products were to produced as 6.15 and 3.50 Dk materials

to meet the predominant industry demand for RF amplifier designs. Table 1 compares the key properties of two standard and two thermally enhanced conductive materials.

The

unique chemistry of the engineered laminate material includes a

significantly reduced TCEr (thermal coefficient of dielectric constant)

as seen in Figure 3. This translates into a more stable signal within any range of temperature fluctuation.

The improvements of this thermally enhanced material include:

- Temperature

insensitive materials help amplifier and antenna designers minimize

dead bandwidth, which is lost to dielectric constant drift as operating

temperature changes

- For antenna designs, a

significant shift in resonance frequency and bandwidth roll off at

specific frequencies, results in lower gain performance, and

- Thermal

stability is critical to phase sensitive devices, such as impedance

network transformers, utilized for matching networks of power

amplifiers

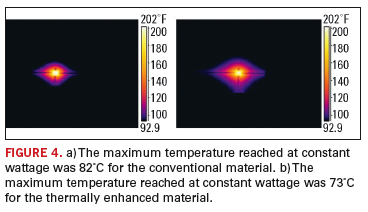

To illustrate the impact of

thermal conductivity both in the perpendicular direction, as indicated

by reduced temperatures measured at the active device, and in-plane, as

determined by the degree of heat spreading, a sample circuit based on

an RF power field effect transistor was developed and thermograms

obtained using thermally conductive laminate and a standard material

with a thermal conductivity of 0.46.

The results

were significant both in terms of the heat reduction at the top surface

and the spreading of the heat in the plane of the board. The resulting

thermograms dramatically illustrate the effect of increased thermal

conductivity. The maximum temperature reached at constant wattage was

82ËšC for the conventional material, 73ËšC for the thermally enhanced

material, a reduction of 10% and more importantly, a reduction of 9ËšC

that could be the difference between life and death for sensitive

junctions. (Figures 4a and 4b).

Summary

Traditional

laminates provide the greatest resistance (insulation) to heat

transfer. Increasing thermal conductivity of the base materials is a

new approach to thermal management in RF designs, with negligible

expected cost implications or impact on signal integrity. These

materials can provide improved component reliability as a result of

improved solder joint reliability. There is less work hardening, less

thermal expansion from lower retained heat and the materials have an

inherently lower CTE. Products designed with these materials will see

improved power handling, and these new thermally enhanced laminates

complement other more traditional thermal management tools. While

designed to meet the demands of RF circuits, these materials can also

be used as a replacement for traditional high performance FR-4

substrates where thermal management is a critical design constraint. PCD&F

Russ Hornung is technical marketing manager at Arlon; This email address is being protected from spambots. You need JavaScript enabled to view it.. Mike Smith is VP of marketing and R&D, also with Arlon, and can be reached at This email address is being protected from spambots. You need JavaScript enabled to view it.. Chet Guiles is an Arlon retiree and industry consultant, and can be reached at This email address is being protected from spambots. You need JavaScript enabled to view it..