Fanout Patterns, Parts 1, 2, 3 and 4

PART 1

Successful fanout solutions provide escape routing for a

combination of serial and parallel nets.

The

effectiveness of a fanout pattern on large BGAs contributes

significantly to the route-ability of a design, which impacts the layer

count and affects the cost of the board fabrication. The fanout of a

BGA is only a part of the routing solution, which may also include

escape traces and general interconnect routing of the pins. The goal of

the BGA fanout effort should be to eliminate the BGA routing as the

primary contributor to increasing layer count while maintaining signal

integrity and fabrication yield requirements.

In a

theoretical approach to BGA breakout, the BGA is analyzed outside the

context of a real design. This kind of solution is a mathematical

excercise in layer reduction that makes unrealistic assumptions and

disregards SI requirements.

Unfortunately, reality

requires much more than just a mathematical solution. Deriving fanout

patterns in a theoretical realm can actually be fairly simple, but

finding effective fanout patterns when all the design and packaging

challenges must be considered is a much more difficult problem.

It

would be ideal to have power and ground pins only in the center of a

BGA, however, power integrity requires they also be distributed among

the signal pins. This distribution is rarely in neat columns and rows,

which would open up considerable routing space.

Figure 1

shows an ideal distribution of ground pins (green). If the BGA had

ground pins aligned this way, and if the mount layer was a GND plane,

then you would see additional room made available on the inner routing

layers.

Unfortunately, most FPGA

vendors distribute the power and ground pins around the BGA or use some

pattern other than columns and rows. The purpose of distributing power

and ground pins is to improve the power integrity. Xilinx often uses a

“Sparse Chevron” pattern as shown in Figure

2. In this figure the ground pins are green and the

power pins are brown.

There

may be some ASICs that have power and ground pins aligned in columns

and rows, however, such an ideal condition is not common, and therefore

effective fanout and routing solutions must incorporate other ways to

reduce the layer count.

Most large BGAs have a

combination of serial and parallel nets that must be routed as

differential pairs and single-ended nets (respectively). Some FPGAs

also allow for nets to be programmed as either serial or parallel.

These devices support multiple I/O performance standards that could

require differential routing.

Differential pairs and

single-ended nets require different trace widths and spacing to

maintain desired impedance, and although it is possible to use the same

spacing rules inside the BGA area, impedance discontinuity may become

significant in some high-speed circuits.

For example,

it is common to have a target of 50 Ω for single-ended nets

and 100 Ω

for differential pairs. Of course the stack up thicknesses and

materials will affect the impedance; yet it is common to see a 0.15 mm

(6th) for differential pair spacing while single-ended nets can have

0.1 mm (4th). Actual trace widths and clearances will vary depending on

the specific high-speed and fabrication requirements for each design.

If

the fanouts are positioned such that differential pairs need to be

split to maintain the trace width and clearance rules, that could also

cause significant signal integrity problems, as illustrated in Figure

3.

Summarizing,

a theoretical fanout and breakout solution that does not take into

consideration the potential for varied trace widths and clearances is

not very useful. The problem becomes even more difficult when each I/O

pin or bank of pins can be programmed to require either differential

pair or single-ended routing.

PART 2

Through-vias provide the lowest fabrication cost but can limit routing density.

This is the fourth in a series of articles on BGA routing methods. My objective is to reveal the routing problems often associated with large pin-count BGAs, and provide the PCB designer with effective techniques that enable higher route density and reduction of layer count.Through-Vias

There are not many fanout options, due to the large via pad relative to the 1-mm ball pitch. Either a “Quadrant Dog-Bone” or “Via-in-Pad” method is appropriate.

Theory: Removing Vias

One

method proposed to increase route channels on inner layers is not to

use fanout vias where possible, for power, ground and unused pins. When

using through-vias, there is very little benefit in not adding fanout

vias for the 30% to 50% of the BGA pins that will likely be assigned to

power, ground or unused. The power and ground pins will be assigned to

the center of the device and distributed among the other pins. It is

highly unlikely that they, or any unused pins will be distributed in

columns and rows.

When using through-vias for

fanouts, rather than trying to gain a few route channels by eliminating

connections to the planes, it is best to gain the power integrity

benefits by adding fanouts for all power and ground pins. In Figure

1,

it is clear that the vias for power and ground are scattered such that

even if they were removed, little would be gained. The outer perimeter

of through-vias dictates the space available for routing, and at least

in the case of the Virtex-4, few of them are assigned to power and

ground.

If an ASIC can be

packaged to provide adequate power integrity and have the power and

ground pins aligned in such a manner so as to increase route channels

(by not using fanout vias) that would be a good design, but this is

likely to be a rare occurrence.

Quadrant Dog-Bone

This fanout pattern has the fanout vias in the center spaced

between the ball pads, and angled in one of four directions.

Advantages over via-in-pad.

- It

opens up additional routing channels in the center row and column,

giving room for two or three more routes per layer, which could

contribute layer reduction, seen in Figure 2.

- On

the side of the board opposite the BGA mount, the column and row

channel gives a convenient place to add capacitors and pull-up

resistors.

- A lower cost and less risk of soldering problems related to

the via-in-pad.

Disadvantages over via-in-pad.

- When using a ground or power plane on the BGA mount side,

the fanout via pads prevent a continuous plane fill under the BGA.

Shifting Through-Vias

Choosing

to place the fanout via outside the center of the ball pad array has a

relatively little benefit to routing due to the lack of space. Any

benefits depend on the design rules. You could move the vias off-center

somewhat in order to form columns and rows, but for every additional

route channel opened on one side, it will close a route channel on the

other – the net result being the same number of route

channels across

the entire BGA.

However, if the design rules are

such that differential pairs cannot be routed together between the

through-vias, and a little more space is required, then shifting

through-vias slightly might make sense.

In Figure 3 and Figure

4,

note that by shifting the vias to the left on one column and to the

right on the next column, you gain 0.17 mm in one and lose 0.17 mm in

the other. These values could vary, depending on your ball pad size and

clearance rules. This option might be useful if you have some critical

signals that require greater spacing within the BGA breakout area.

Another

reason for shifting through-vias while using Quad Dog-Bone patterns is

to maximize the amount of plane fill on the mount layer. Again, any

benefit is dependent on the design rules.

Via-in-Pad

This pattern has a simple solution, which is to add a

through-via in the center of each of the desired BGA ball pads as seen

in Figure 5.

Advantages over quadrant dog-bone.

- If you have a ground or power plane on the BGA mount side,

the fanout via pads allow a continuous plane fill under the BGA.

- If

you do not use the mount layer for a plane, then you have an additional

routing layer for the BGA – albeit a surface layer, which may

cause

impedance problems when using high-speed nets.

Disadvantages over quadrant dog-bone.

- There are no additional route channels in the center column and row.

- There is less room for capacitors and resistors on the opposite side under the BGA, since the fanout via array is full.

If the BGA has unused pins and you do not add fanout vias for them, there will be available room for components.

- There will be a slightly higher cost for filling the vias and ensuring a smooth surface when soldering the ball pads.

- There

is some risk of BGA soldering problems (delamination or pop corning)

with via-in-pad when using lead-free solder. An experienced assembly

company should be able to manage this risk.

Better Methods

Although

through-via stackups generally provide the lowest cost fabrication, the

large size of the via severely limits your ability to maximize route

density and therefore leads to excessive layer count. The next article

will clearly demonstrate the benefits of using blind and buried vias.

PART 3

Aligning blind via fanout patterns can significantly increase route density.

We

have already come to the fifth article in this series on BGA breakout

and routing methods. Those who have been following along have read

about unusual and upcoming packages, theoretical breakout solutions,

and the limited set options when using through-via fanout patterns. The

intent in all these articles is to provide ideas and methods that will

enable greater route density for BGAs, resulting in fewer layers while

still maintaining signal and power integrity.

Blind and Buried Fanouts

The

basic principles for effectively using fanout patterns can be applied

when using blind and buried vias, even in a laminated stackup. Although

the via sizes are still larger than in an HDI stackup using micro-vias,

the blind and buried vias are still small enough to obtain significant

route density gains.

Shifting Vias

In Figure 1, the blind-vias have

been shifted into columns with the intent of opening up additional

routing space. In Figure 2, you can see

that significant space is created as compared to the unshifted pattern

in Figure 3. Figure 2 shows how shifting

the vias can add an additional 24% increase in the number of escape

traces at the edge of the BGA.

Observe

that the blind vias are not in a straight column because via size and

via-to-via clearance (0.1mm) forces them to be staggered.

The advantages of shifting vias include:

- 24% increased route density per layer over through-vias and unshifted blind vias.

- More room for a ground plane on the mount layer (but not as much room as with via-in-pad).

- If you route the high-speed single-ended nets on the layers using blind vias, via stubs are eliminated and via-to-via crosstalk is minimized.

- Any

signal routed on the blind via layers will not need to have a buried

via, thus opening up route space on the buried via layers as well.

The disadvantage is that blind and buried via stackup is

slightly more expensive than a through-via stackup.

As shown above with blind vias, it is clear that shifting the via position can increase route density. When using HDI microvias, shifting the fanout locations can improve route density even more. Increased route density means potentially fewer layers and lower cost. There are some general principles related to shifting vias that can help make the effort successful.

Differential Pair Coupling and Pin Swapping

When

applying a shifted via pattern in order to increase route density, one

of the results that will possibly need to be managed is that as the

transition progresses through the layers with different patterns in the

via span, the differential pair compliments may be moved away from each

other. Figures 4 and 5

illustrate

this problem. The ball pads for the differential pair compliments may

be designed in the FPGA or ASIC to be placed closely to each other, but

as fanout vias are added, the compliments may end up further apart than

originally intended.

A

good solution, especially for FPGAs, is to pin swap, so that the ball

pads are aligned in a manner that allows the fanout vias to remain

close to each other. In Figures 4 and 5, swapping the differential pair

compliments into the “A” and

“A” locations will optimize the coupling.

The

ability to swap pins will be limited by bank locations, differential

pair or single-ended pin assignments, and power and ground pin

distribution. Finding the most effective swapping patterns (aligned

vertically, horizontally, or on a diagonal) will depend on the fanout

via pattern used in that area.

Reducing the Effective Size of the BGA

If

the ball pads around the perimeter can be fanned-out and routed on the

blind via layer (layer 2), then the effective size of the BGA routed on

the buried-via layers (Figure 6) will

become 1024.

With that number of pins, breakout and routing of the BGA is no longer

the primary contributor to layer count, especially since the innermost

pins in most BGAs are usually dedicated to power and ground.

Principles

Aligning blind via fanouts in well-organized patterns can significantly increase route density on those layers where it is incorporated. Increased route density means that more rows of ball pads around the perimeter can be routed on the blind via layers, which will result in effectively decreasing the size of the BGA routed on the buried via layers.

PART 4

Creating effective fanout patterns for microvias in an HDI stackup.

HDI microvia fanouts for laser drilled micro-via stackups use the same principles as mechanically drilled blind and buried vias. The variety of stackups and smaller via sizes provide for tighter shifted column and row patterns, improved route density and greater flexibility in assigning routes to buildup layers than does standard laminated cores.When using HDI, the blind micro-vias allow for greater route density, and therefore potentially fewer total layers required for routing. Of course, the number of layers accessible by the micro-vias will significantly affect the overall route density. The fanout patterns analyzed in this context will be for the following types of HDI construction:

1+N+1 = Type II (Layer 1:2 microvias with buried vias in a laminated core)

2+N+2 = Type III (Layer 1:2, 2 to 3 microvias with buried vias in a laminated core)

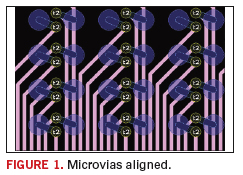

Layer 1:2 microvias (1+N+1)

If Layer 1 is used for a ground plane and not for routing, then the fanouts need to be patterned to maximize Layer 2 route density. The same patterns described in the previous month’s article for blind vias can be used for microvias, however, since the microvias are smaller, they can be further compacted to gain additional route space.In Figure 1, the 1:2 microvias are aligned in columns to maximize route density (12% improvement over shifted blind vias, 36% improvement over quadrant dog-bone through vias.) It is easy to see how route density can be increased when using via-in-pad methods.

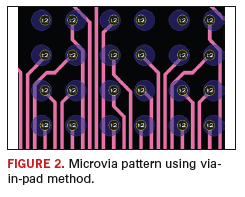

If the vias are shifted inside the pads as shown in Figure 2, you can open up additional room for the escape traces.

If only one layer is available for the escape traces, as is the case with a 1+N+1 stackup that has a ground plane on the surface layer, then it is important to use a shifted via pattern that is allows for aligned microvias around the BGA perimeter. This will allow space for the power and ground to extend through the board using additional buried and blind vias.

Layer 1:2, 2 to 3 microvias (2+N+2)

Again, assuming that Layer 1 will be a ground plane, then the fanouts need to be patterned to maximize the Layer 2 and Layer 3 route density. Figure 3 and Figure 4 show how effective the general principle of aligning vias works to open additional route space on inner layers. Figure 3 shows that the shifting of vias not only provides additional route density, but it also opens space for uninterrupted ground fill. Also note how nicely the ground via fits, and the how the copper fill and clearance around it provides for ease of manufacturing. The thermal relief ties are also rotated off the 45-degree center, to maximize the connectivity and make room for the nearby fanout via.

In Figure 4, note the significant space for routes after shifting the vias. In this case, the traces are routed as single-ended nets, however, if the nets were differential pairs, there would be plenty of room to route three sets of differential pairs between the aligned vias. Of course, practical applications such as these may vary depending on design rules.

The power (orange) and ground (green) vias are paired because both the 1:2 vias, but also the 2:3 vias can be seen on Layer 2. Observe as well the wide-open space for traces on Layer 3, where the buried via starts.Results may vary depending on actual design rules. In the above examples, the trace widths are 0.1mm/4th and the via pad size is 0.254mm/10th.

Effective fanout patterns can significantly increase route density. Designs with through vias under BGAs have limited options, but by using laminated blind vias, route density can be increased 24%, and using HDI micro-vias allows a 36% increase in route density.

These four articles on fanout patterns clearly show that aligning blind-vias or micro-vias is a very effective method for potential layer reduction through increased route density.

The next article will present a new concept for organizing multiple via patterns for a single BGA, and the positive impact it has on increasing route density. PCD&F

Charles Pfeil is an engineering director for Mentor Graphics, Systems Design Division; This email address is being protected from spambots. You need JavaScript enabled to view it.; mentor.com/pcb. He has authored a book, BGA Breakouts and Routing, which explores in greater detail the content of this column. Please visit mentor.com/go/bga to order a copy.