Improving Fabrication Yields by Design

The PCB designer is the architect for improved PCB yields.

A major requirement in improving board fabrication yields is doing

it right the first time, because once the PCB fabrication process is

complete there is really no way to go back to fix major mistakes. In

some cases you can mitigate design issues during the PCB assembly

process, but during PCB fabrication, once layers are laminated and the

holes are drilled, you cannot easily undo the process to make

corrections.

Therefore, to improve fabrication

yields during and after design layout, it’s critical to follow the

detailed fabrication notes and drawings, specifically calling out every

item that requires any kind of explanation. This includes stack up

data, layer construction information, material call outs, as well as

drill charts specifying hole counts and symbols, whether drill holes

are plated, and any similar information.

Notes and

drawings must not have sketchy or ambiguous information, nor should

they lead the PCB fabricator to make “guesstimates” about some of the

directions. Fabrication notes and drawings must have clear-cut and

precise information in their instructions – assumptions are not

allowed. If questions arise, the OEM customer should be consulted, and

the OEM should resolve any uncertainties.

A good rule

of thumb is to engage the fabrication house during PCB layout/design

stage. After the designer creates the stack up for impedance control,

it’s a good idea to get it verified before the files are released to

the fab house. Conversely, the fab house can play a reciprocal role by

providing the designer with recommendations and suggestions for

boosting yields. For example, a fab house may recommend material

changes for a specific application that are better suited to increasing

yields than those a designer specifies.

Also, it is

a good idea to check the capabilities of a fabrication house before

releasing a job to them. If the PCB design calls out for 3 mil lines

and spaces, and the fab house does not have the capability to generate

this type of feature, they can inadvertently over or under etch traces,

causing open or shorts resulting in yield issues. Therefore, working

together, the designer and fab house engineer can resolve any question,

issue, or ambiguity that arises at an early stage in the design

process, before the design ever reaches the fabrication floor.

The Importance of Fabrication Drawing

The

PCB designer is the lynchpin for improving fabrication yields from the

start. The fabrication drawing – the result of the PCB layout/design –

is the tool they rely on to achieve this objective. A seasoned designer

always finishes their layout by providing a complete fabrication

drawing. An efficient fabrication drawing has four components – notes,

mechanical dimensions/drawings, stack up callouts, and a drill chart

seen in Figure 1.

Fabrication

notes include a wide range of technical details and instructions. The

more complete and accurate they are, the more likely that the

fabrication house will be able to produce the PCBs with requisite high

yields. The following are some of the critical areas that should be

covered in fab notes.

It is important to list the

IPC class (I, II, or III) on the fabrication notes. Also, the designer

should specify the required board materials and surface finishes such

as HASL (lead-free or tin-lead type), electroless nickel and immersion

gold (ENIG), immersion silver or tin. If it’s gold, what is the

quantity and type? A typical soldering applications might call for 3 to

5 microinches of gold over 150 to 200 microinches of nickel. A higher

thickness and different type of gold would be needed for specialized

applications such as wire bonding. The designer should also include,

whenever possible, a note designating a secondary (equivalent) material

and manufacturer name if the primary choice is not available at the

fabrication house. It may take a week or more to acquire material,

causing OEM product delivery delays. That’s the level of detail the

designer must include in their notes.

Ensuring that

automated optical inspection (AOI) is used is another critical step in

board fabrication. AOI checks inner layers to ensure there are no opens

or shorts on the board, and that layer-to-layer registration is

properly aligned. For example, a note to a fabricator can simply state:

“Please make sure Layers 2, 3, 5, and 6 are AOI verified before

laminating the layers.”

Solder mask information

must also be covered, including if a solder mask is required on one or

both sides of the board, halogen content considerations and also

designating the color of the solder mask. In addition, it is always a

good idea for the designer to mention a few preferred solder mask

manufacturers. Fabrication notes must also detail maximum warpage per

square inch that the designer will allow, and this should be in

accordance with IPC guidelines.

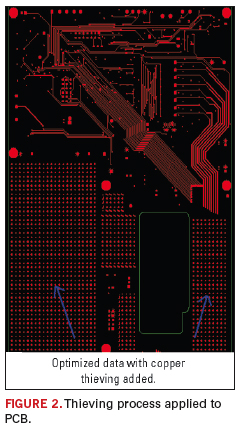

The designer also

should include a note on the thieving process that allows for even

copper distribution on the board. Thieving adds non-conductive copper

material to the board that balances copper weight on the board’s entire

surface, so that when etching is performed, it is uniform over the

board’s surface. This minimizes the creation of either opens or shorts.

Figure 2 shows a PCB design with copper thieving added.

Designing For Odd-Shaped Boards

When

it comes to fabrication notes, mechanical dimensions and drawings

require equal attention from the designer. This is especially true for

odd sized or unusually shaped boards that use radial angles to define

curvatures or slot dimensions. When creating a fabrication drawing for

such boards, the designer must specify even the smallest detail in

lengths, widths, and angles. The designer must carefully designate any

holes that reference each other, especially if they are at a specific

angle or run concurrent to each other.

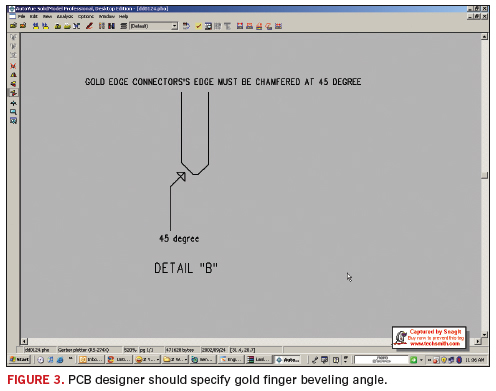

Gold

fingers, like cables and chassis wires, are used to connect daughter

cards to a motherboard or other subsystems, and when providing details

on the beveling of the gold fingers at the edge of the connectors, the

designer should specify the angle and at what levels the gold fingers

should be beveled (see Figure 3).

The

datum point 0,0 must be specified, so that every other dimension is

measured from that original point. Cutouts, slots, and holes must also

be meticulously designated. On the drawing, there are two sides for

reference designators. At times, the designer might note a special

feature on the bottom side that isn’t required on the top side. This

distinction must be made in the fabrication drawing. If not, the

fabrication house is left to make what perhaps can be a faulty

assumption. Other details the designer must include would be any

special features, like counter sink holes or sequential lamination.

Stack

up callouts specify board thickness, composition of internal layers,

pre-preg thickness, and copper ounces per square inch used on the

board. At the layout stage, the designer should perform precise

calculations on the amount of current that will flow through the board.

The callout specifies the thickness of copper (measured in ounces) to

comply with current requirements. What must be avoided is the

fabrication house relying on their own judgment, or making a decision

using no calculations at all. (Note: an “inaccurate judgment” is not

the fault of the fabricator, it’s a design error.)

When

calling out for impedance control requirements, a precise tolerance,

such as 5% or 10% should be specified. For high-speed designs,

impedance requirements could be single ended, or multiple differential

impedances. Since there are many factors that can change the impedance

on a board, a seasoned designer is always aware and mindful of these

factors, which may include the stack up of the board, number of ground

planes, trace width and thickness and the dielectric constant.

Lastly,

the drill chart covers four aspects – the symbols used, the size of the

tools, the quantity of each drill size, and if holes are plated or

non-plated. When defining drill symbols to distinguish multiple drill

sizes used on the board, a separate precisely defined symbol should be

used to make this distinction clear and without ambiguity.

Accurate

and comprehensive attention to detail should result in as near an ideal

fabrication drawing as possible. A drawing of this caliber eliminates

most or all of the uncertainty in the planning and computer-aided

manufacturing (CAM) stages, as well as many that may be raised by the

fabrication house.

The CAM stage allows the

fabrication house to review the different files generated in the PCB

layout process. This includes Gerber files, which generates renderings

that show layers, power and ground planes, drill holes, etc. At this

point, oversights and potential problems can be corrected, as the

efficient use of a sophisticated CAM tool will uncover discrepancies,

such as half moons, stubs, or missing connections.

Assumptions and Common Sense

Wrong

assumptions can cover many aspects of the PCB fabrication process that

may include surface finishes, board material, copper plating, and other

smaller details such as plated-through holes (PTH) versus non-plated

through holes. In the case of the PTH, it can create a short between

the chassis and screw tightening the board, if specified incorrectly.

At times, surface finish may not be specified by the OEM customer, and

an assumption may be made to apply a HASL surface finish, but in a

lead-free application, a silver or gold finish might be required to

withstand the high thermal profile during reflow.

Improving fabrication yields requires the designer to use plain old common sense, as well as applying their extensive experience and know-how. A seasoned designer knows precisely where the pitfalls exist in a board design, and applies all the tricks and techniques they have learned from previous experience. A considerable amount of that design knowledge results from practical hands-on experience, rather than from textbooks or formal training. PCD&F

Zulki Khan is president and founder, Nexlogic Technologies and can be reached at This email address is being protected from spambots. You need JavaScript enabled to view it..