Holewall Pullaway and Resin Recession

Maintaining the electroless copper process chemistry within recommended range can alleviate many common plating problems.

We

devoted the last several columns to voids and holewall pullaway. Before

moving on to discuss other defects, this edition will discuss resin

recession and finish with a case study on Holewall Pullaway (HWPA).

While they are two unrelated issues – one is a defect and the other is

not – both will receive appropriate discussion.

Resin

recession is primarily a material issue, not a plating/metallization

defect. On casual inspection, resin recession can be, and often is,

confused with HWPA. Resin shrinks during solder shock and other thermal

excursions, and resin that is not completely cured will be more prone

to shrinkage.

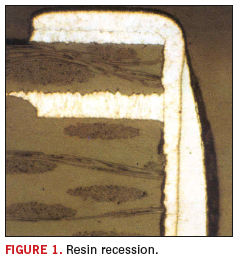

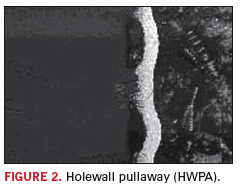

An example of resin recession is shown in Figure 1, and holewall pullaway in Figure 2.

One way to determine the difference is to look carefully at a

cross-section. In Figure 1, the plated copper edge is very straight,

and the resin is pulled back, indicating resin recession. In Figure 2,

one can see that the plated copper vertical sidewall is “bowed

outward.” The bowed copper is often seen as minor “blisters” or areas

where the copper has lost adhesion.

Resin

recession is often seen with under cured laminate. To check the degree

of cure, you can use thermal mechanical analysis or differential

scanning calorimetry. Undercured material will shrink or recede during

thermal excursions.

Depending on the type of

chemistry employed for desmear, certain material combinations can

exaggerate the degree of resin recession. If the solvent used prior to

permanganate is overly aggressive with respect to its penetration into

the resin, recession will be evident. If using a 100% organic solvent

for pre-conditioning, consider a different solvent system or one with a

reduced concentration to minimize penetration.

A PCB

fabricator recently reported a an increase of sporadic holewall

pullaway. The defect was exhibited in both small and large diameter

vias in standard FR-4 material. Defects were seen on multilayer designs

of 6 to 8 layers. For the past two years, a standard EDTA based

electroless copper (medium deposition type) was employed. The process

was designed to deposit 50 to 60 microinches of copper in 30 minutes.

Solution operating temperature was specified to be 75 to 85 degrees F.

The

operators were interviewed and suggested “nothing had changed” in the

process operation, yet visual inspection of some panels showed a

noticeably darker color to the plated copper on some product. In

addition, weight gain measurements yielded information that indicated

that occasionally, deposits as high as 90 to 100 microinches of copper

were recorded. Interestingly, the operators were not concerned with

this discrepancy, but solder floating several coupons from these

overplated boards showed a high level of HWPA. The main cause is quite

simple – the electroless copper deposit was deposited in a stressed

condition. Remember, this particular electroless copper process is

formulated to deposit 50 to 60 microinches in 30 minutes, not 90 to 100

microinches in the same time period. Keep in mind that when the

electroless copper process is operated outside of normal operating

parameters, problems can happen.

Now let’s get to

the root cause of the problem. Often it’s in the details. The

electroless copper solution was maintained with a single channel

controller that monitored the copper content in the working solution.

Based on the copper analysis, the other chemicals were replenished in

the standard proportion required to maintain the process in the working

range. This means that the sodium hydroxide content was added based on

the copper that was required in the solution.

Unfortunately,

the sensor for the copper was not calibrated properly. Thus, the

controller thought it was seeing a lower level of copper than what was

really in solution. In reaction to the incorrectly measured, low copper

levels, the controller called for the addition of copper and sodium

hydroxide in amounts that where much higher than the electroless copper

process needed. The higher than required levels of hydroxide drove the

deposition rate beyond the designed 50 to 60 microinches, resulting in

the stressed, heavy copper deposit.

Remember, any

process change that can lead to a greater than normal deposition rate

can cause holewall pullaway. All chemistries should be operated and

maintained according to the manufacturers’ recommendations. PCD&F

Michael Carano is vice president for OM Group Inc. and can be reached at This email address is being protected from spambots. You need JavaScript enabled to view it..