Panel Rails — What Are They?

I referred to "panel rails" in my blog about V-score panels, but I didn't explain the "whats" and whys" of panel rails. You might find yourself asking "what are panel rails and why would I want to use them?"

Well, first of all, for our Full-Proto service, we don't require panels or panel rails. We'll take just about any old board that's bigger than 0.75" x 0.75" and smaller than 14.5" x 19.5" and run it through our machines. For our short-run production service, we only require panelization for boards less than 16" sq.

That being said, panel rails do have a purpose. They give the machines a spot to grab onto without coming close to components. They're also a convenient place to put fiducials (more fiducial info here).

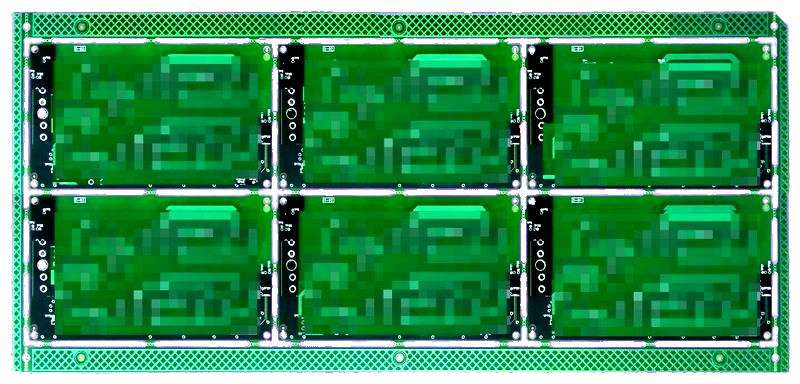

As you can see in the image below, the panels give a clear area for handling the panel.

There are two important things to note about this panel. First, look closely at the four outside corners. You can see the scoring for easy separation of the rails. This designer made sure that there isn't any copper where the scores are. That's the right way to do it. The V-Score blog item shows a panel rail done the wrong way, with copper across the cut.

Next, this board has fiducials. Good. But, the fiducials are in a symmetrical pattern. Not so good. IPC-7351b-3-10 specifies a non-symmetrical pattern so that the board can only be processed in one orientation.

DUANE BENSON is marketing manager at Screaming Circuits (This email address is being protected from spambots. You need JavaScript enabled to view it.m); This email address is being protected from spambots. You need JavaScript enabled to view it..