Semi-Additive Process for Low Loss Buildup Material in High-Frequency Signal Transmission Substrates

A novel material promotes signal integrity at high frequencies through high plating-resin adhesion and a smooth dielectric interface.

Semi-additive processing (SAP) is widely used in the manufacture of ultra-fine circuitry on different dielectric buildup materials. Good candidates for dielectric buildup materials should provide good processability, as well as excellent chemical resistance, good dimension stability (i.e., low coefficient of thermal expansion) and sufficient mechanical strength. Such properties make circuit manufacture possible by eliminating smear and warpage through multiple chemical treatment, cure and reflow processes. Moreover, they ensure good circuit integrity and long-term reliability of electronics used in a range of temperatures. In addition, potential candidates should have excellent electrical properties, including low dielectric loss tangent (Df) and low dielectric constant (Dk), which are essential for high-speed signal transmission.

To decrease signal loss and increase signal integrity at a high transmission speed, the surface of dielectric materials should be very smooth, with excellent adhesion between them and fine-line circuitry. The standard SAP process dramatically roughens the dielectric surface to seek sufficient adhesion through an anchor effect, however. Advanced SAP processes should use very mild surface texturing but add significant chemical functioning to provide high plating-dielectric adhesion with a very smooth interface in between.

A new process (SAP-RIGID) for low-loss buildup materials has desmear roughness of Ra= 80±18nm and adhesion pf 658±18 gf/cm at various processing conditions.

Along with the process flow, the current work also presents results and discussion regarding characterization of the morphology and composition of resin or metal plating surfaces using scanning electron microscopy (SEM) and energy dispersive x-ray spectroscopy (EDX), surface roughness analysis, and plating-resin adhesion evaluation from 90o peel tests.

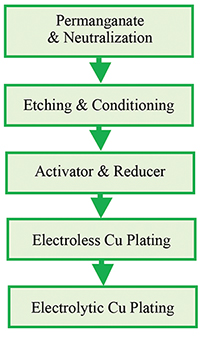

The flow for the new semi-additive process is shown in FIGURE 1. Generally, it includes similar steps as traditional SAP, which makes it adaptable to existing equipment sets. In detail, the new process combines metallization techniques tailored for rigid dielectric materials, including surface pretreatments before plating (including permanganate and neutralization, etching and conditioning, activation and reducer), and electroless and electrolytic plating techniques.

Figure 1. SAP-Rigid process flow.

In the pretreatment steps, the dielectric material is imparted with a very smooth but highly functionalized surface. After activating and reducing, a thin copper seed layer with a thickness adjustable from 0.25 to 1.00µm (i.e., 10 to 40µin) was applied on the dielectric surface using an electroless copper plating process. This copper layer provides the film surface with good electrical conductivity, which results in a uniform electrolytic copper thickness across the panel width. In the final step, electrolytic copper plating is used to build up copper thickness to the ideal value. The influence of each processing step is demonstrated and detailed below.

Surface pretreatment. For the novel SAP, surface pretreatment starts with a 12 to 25 min. permanganate process at 80oC, which generates abundant carboxylate functional groups on the dielectric surface while roughening it slightly. After that there is a neutralization step, followed by a conditioning step in a caustic solution. This short time (five to 10 min.) etching and conditioning step can be done at a wide temperature range from 50o to 70oC. This surface pretreatment flow is milder than traditional SAP for rigid dielectric materials, which normally starts with a strong sweller. The sweller step is normally operated at high caustic content, high temperature for 20 to 30 min., which is eliminated in the novel flow.

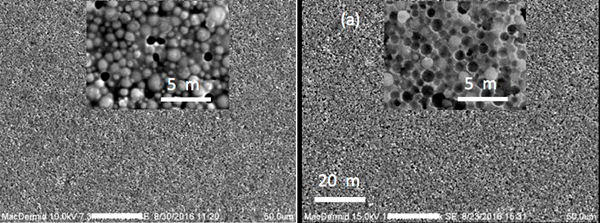

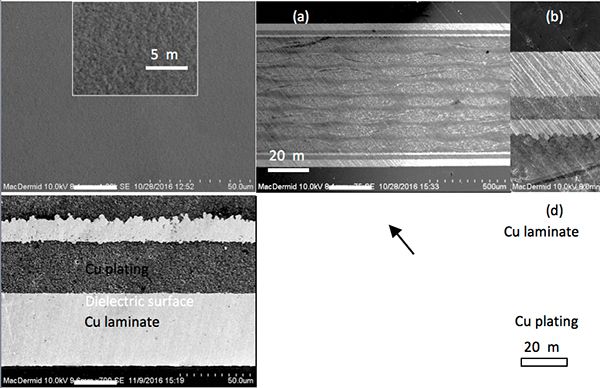

As a result, after surface pretreatment, the roughness on an epoxy and/or cyanate ester type dielectric surface is still as low as Ra=80±18nm, compared to that of raw dielectric material at Ra= 50±5nm as received. The dielectric surface before and after pretreatment is also compared using SEM (FIGURE 2).

Figure 2. SEM images for the dielectric material (Material A) before (a) and after (b) SAP-Rigid pretreatment at 1000× magnification. Inserted are some of their surface enlarged at 5000× magnification respectively.

Compared to the raw dielectric surface, there are obviously more dents than sphere-like bumps on the treated dielectric surface. These dents are homogenously distributed and were formed due to release of some glass fillers from the surface after treatment.

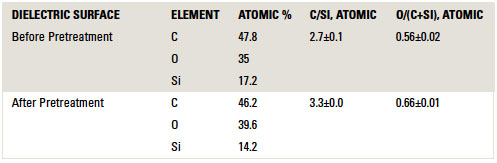

Such changes on the topography of the pretreated dielectric are accompanied with modification on its surface chemistry, which can be reflected from the atomic ratio on dielectric surface. As shown in TABLE 1, the EDX results demonstrate that the C/Si atomic ratio on pretreated dielectric surface increased to 3.3±0.0 from that of 2.7±0.1 on the raw one (p<0.001). Moreover, the O/(C+Si) atomic ratio on pretreated dielectric surface increased to 0.66±0.01 from 0.56±0.02 (p<0.001). Considering the two sets of comparisons, it can be concluded that the surface pretreatment in the novel SAP significantly introduced functional groups with carbon at higher oxidation stage.

Table 1. EDX for Atomic Composition on Dielectric Surface Before and After Surface Pretreatment in SAP-RIGID, Separately

Furthermore, the chemical groups on pretreated and raw dielectric surfaces were also investigated using ATR-FTIR spectroscopy. (Spectra are not shown here.) The absorption from –OH stretching is around 3100-3600 cm-1, which has the shape of a bump. A new big bump-like absorption from 3100-3600 cm-1 was found on the pretreated dielectric surface. It further proves that abundant carboxyl functional groups were successfully introduced to the dielectric surface after the pretreatment.

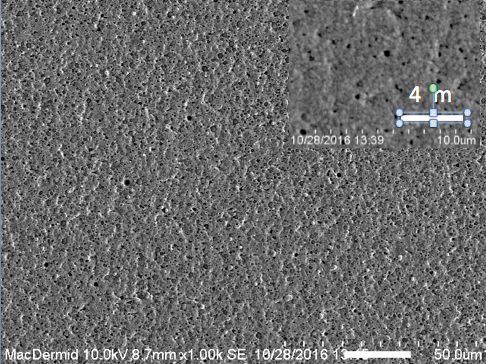

Electroless Cu plating. Following surface pretreatment, ionic activator and reducer are used to seed the dielectric surface with palladium. Then direct metallization processes are utilized to build up the dielectric-metal laminate. In detail, an electroless copper plating is applied to obtain a thin copper seed layer. This electroless copper bath is operated around 27o to 35oC, and the plating rate in it can be tailored from 0.4 to 15µin/min by adjusting plating temperature and additive contents. FIGURE 3 shows SEM images for the morphology of electroless copper layers generated at 0.75µin/min. with a thickness around 20µin.

Figure 3. SEM image (1000× magnification; inserted, 5000× magnification) for electroless Cu layers plated on pre-treated Material A at 0.75 min/min with a thickness around 20µin.

Electrolytic Cu plating. With the new technology, an electrolytic copper plating process was used to build up copper thickness. FIGURE 4(a) exhibits the topography of electrolytic copper plating on the dielectric material. By adjusting current density and plating time, the copper thickness could be tailored to the ideal value with preferred plating rate, which proved to show little influence on dielectric-plating adhesion using the novel SAP.

Figure 4(b/c) shows cross-section images of the plated dielectric laminate. Apparently, electrolytic plating generated uniform copper plating layers on both sides of the novel SAP-processed dielectric board. In Figure 4 (c/d), special attention should be focused on the resin-copper interface. The interface between the inner copper laminate layer and resin layer shows many copper feet providing bonding between the copper laminate and inner resin layer through an anchor effect, similar to traditional metallization methods. On the contrary, the interface generated with the novel SAP between the dielectric surface and copper plating is much smoother with no copper foot.

Figure 4. (a) SEM images (1000× magnification; inserted, 5000× magnification) for final electrolytic Cu layers on Material A. (b) SEM images showing cross-section of Material A with electrolytic Cu plating on both surfaces. (c-d) SEM images showing enlarged areas at the cross-section.

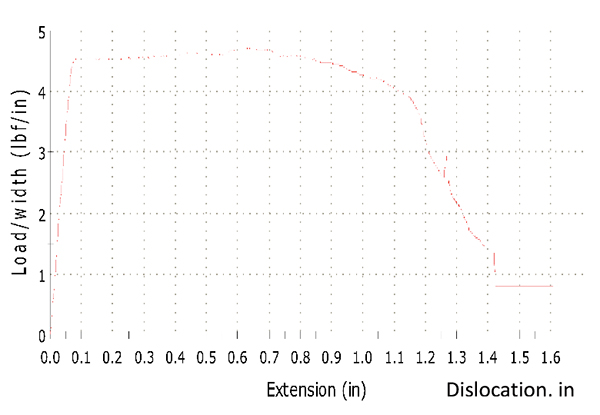

Dielectric-plating adhesion. Adhesion between the treated dielectric surface and plating was evaluated by the bond strength at the dielectric-plating interface by a 90o peel test. Freshly processed with the novel SAP, plated dielectric samples were cut into 2.54 × 5.72cm L specimens and tested. FIGURE 5 shows a representative load versus dislocation profile from a 90o peel test on Material A processed with the novel SAP. It is evident the dielectric-plating adhesion is uniform and averaged at 670 gf/cm through the testing length, regardless of the edge effect at the end of the specimen.

Figure 5. Representative load versus dislocation profile from 90˚ peel tests showing dielectric-plating adhesion processed with SAP-Rigid on Material A with electrolytic Cu plating around 20µm.

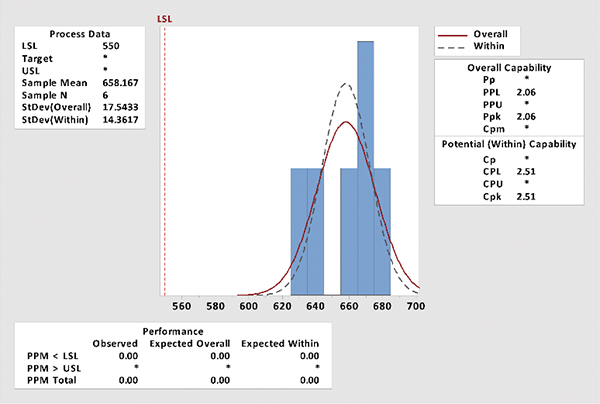

To evaluate the repeatability and consistency of the adhesion, more replicate experiments were performed by processing Material A using the novel SAP. At the same time, the capacity of the novel SAP process was evaluated based on the adhesion results. As demonstrated in FIGURE 6, using the novel SAP process, the dielectric-plating adhesion averages 658±18gf/cm. Compared to a general adhesion lower limit for the adhesion on Material A, which is 550gf/cm, the novel SAP has a short-term capability at 2.51 and a long-term capability of 2.06. In other words, the novel SAP process is a typical Six-Sigma capable process, capable of consistent and continuously satisfactory adhesion.

Figure 6. Statistical analysis of dielectric-plating adhesion and capacity evaluation of SAP-Rigid process on Material A with electrolytic Cu plating around 20µm.

Other Dielectric Materials

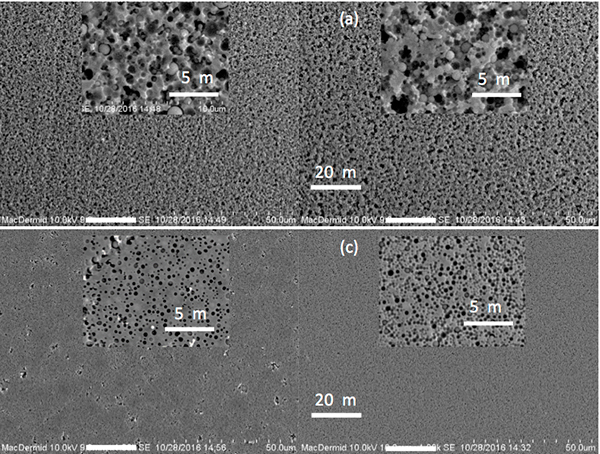

In addition to investigation on Material A, some preliminary studies were also carried out by applying the new SAP technique on other rigid dielectric materials (Material B, Material C, Material D and Material E). The surface morphology of these dielectric materials after novel SAP pretreatment is shown in FIGURE 7.

Due to their various chemical and physical properties, Material B, Material C, Material D and Material E responded differently to the current novel SAP pretreatment. Some gained a rougher surface (Material B and C), while some maintained very smooth surface (Material D and E). Adhesion data are summarized in TABLE 2.

Figure 7. SEM images (1000× magnification; inserted, 5000× magnification) for different dielectric surface after pretreatment in SAP-Rigid: (a) Material B, (b) Material C, (c) Material D, and (d) Material E, respectively.

Table 2. Plating-Dielectric Adhesion on Different Dielectric Materials

Apparently, processed with the novel SAP, the four dielectric materials achieved bonding to the copper plating, which cannot be explained simply by the surface roughness. For example, Material E showed very low surface roughness (down to 19nm) but sufficient adhesion. These results prove the good dielectric-plating adhesion from the novel SAP is based on chemical bonding rather than an anchor effect.

As is well known, a chemical-bonding-based SAP process should be developed with chemical and thermal treatments tailored to the surface composition, surface chemistry and Tg of the polymer phase on the top layer of each dielectric material. As shown in Table 2, the new SAP has good potential to be applied to more dielectric materials, with minor adjustment to chemistry and fine-tuning of processing parameters.

Conclusions

The novel SAP process combines innovative etching, conditioning and direct metallization techniques. It contains similar processes as traditional SAP, which makes it adaptable to existing equipment sets. Moreover, the processed dielectric surface can maintain low surface roughness, and supports superior dielectric-plating adhesion through chemical bonding.

The novel SAP has been successfully applied to epoxy or cyanate-ester type dielectric materials (Material A) and achieved very low desmear roughness (Ra= 80±18nm) and excellent adhesion (658±18gf/cm). Considering the general lower limit for the dielectric-plating adhesion on Material A (550 gf/cm), the application of the novel SAP is a typical Six-Sigma capable process both in short-term (Cpk = 2.51) and long-term (Ppk = 2.06). In addition, novel SAP also opens good potential on other dielectric materials widely used in the current SAP market.

Ed.: This article was first presented at IPC Apex Expo in February 2017 and is reprinted here with permission of the authors.

, is research project manager, is senior application manager, is research project manager and is senior research fellow at MacDermid Enthone Electronics Solutions (macdermidenthone.com); This email address is being protected from spambots. You need JavaScript enabled to view it..