Electrical Performance in a Thin Package

Polyimide pushes the electrical envelope without swelling the form factor.

Mobile devices are a fast-paced, growing market. Flexible printed circuits are a key element in making these devices smaller and thinner, while increasing functionality. Let’s recap how has flex use evolved in the mobile device market.

Flex circuits were originally used as interconnect for features located on different levels within an assembly. By and large, these flexes were relatively simple – not

much more than a thin jumper cable. As mobile device designers conjured the “flip phone” form factor, flex circuits fulfilled the need for dynamic bending applications in the hinge of those devices. Flex gained more complex features, with multiple bends and air gaps, some with components placed on them. As assembly increased, flex helped enable “slider phones” with dynamic, rolling features with expanded functions such as full keyboards and larger displays.

As mobile phones competed to be the “smartest” on the block, designers were pressed to cram in a wider range of rich media, connected functionality. Flex allowed designers to fill smartphone chasses with a variety of components and modules with multiple small-radius bends, leading to reinforced zones with metal or plastic for side keys, cameras, displays and more.

Here’s where we are today: thin, flat and highly populated flexible circuit assemblies with a range of components on one or both sides of the board. One of the most important applications is the ability of the boards to bend, flex and be shaped into 3D forms. While these mechanical features enable the addition of new features, it’s the electrical properties of the flexible substrates that play a critical role in enabling the high-definition user experiences we enjoy in mobile devices today.

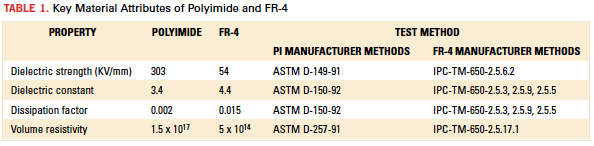

When I look at the electrical properties of polyimides and other thin flexible substrates used in FPC fabrication, I find the electrical properties of FPC dielectrics are often superior to the equivalent FR-4 material sets (Table 1).

[Ed.: To enlarge the figure, right-click on it, then click View Image, then left-click on the figure.]

How do the electrical properties in Table 1 enable the FPC to do what an FPC does: be very thin and bendable while maintaining signal performance? As a dielectric material, polyimide has a few advantages over FR-4, higher dielectric strength and volume resistivity. The dielectric strength is a measure of the electrical performance of a material as an insulator. It is defined as the voltage required to produce a dielectric breakdown through the material. Volume resistivity is the measure of a material's ability to prevent an electrical current through its structure. The higher the surface/volume resistivity, the lower the leakage current and the less conductive the material is. These two properties combined are what enable flex manufacturers to use very thin layers of material between conductors to provide adequate electrical isolation. This advantage works not only in the horizontal plane with conductive traces, but also enables a closer space between adjacent via barrels.

The result: Polyimide’s electrical properties enable FPCs to be 70% thinner than an equivalent PCB.

When looking at the dielectric constant and the dissipation factor, polyimide generally compares quite favorably to FR-4. While I’ve excluded the impedance calculation for the sake of sanity, the takeaway here is that lower dielectric constants (Dk) enable FPCs to maintain larger trace dimensions and thin dielectrics and still maintain the desired impedance control, whereas designers must compensate for materials with a higher DK with finer (and more difficult to produce) traces, as well as thicker dielectrics. As for dissipation factor (Df), the measure of the loss-rate of energy along an insulated conductor, materials with a lower Df enable FPC to achieve impedance requirements and signal integrity, while preserving FPC’s thinness advantage over an FR-4 PCB.

It’s fair to ask, How much difference could there really be? Take a PCB. Reduce the thickness by one-third, then bend it around and under or over that troublesome battery that always seems to be making the designs thicker than your manager wants them.

As we look to the future of new devices with new functions, we believe FPC’s strengths to bend and flex will continue to be a clear value add, but it’s the electrical properties of today’s polyimides, making it possible to achieve controlled impedance and high-frequency performance in a thin and lightweight interconnect that will be of increasing value to electronics product designers.

Simply put, today’s devices have no space to spare, so even if your interconnect application does not need to bend, do not eliminate the FPC as an option. Think of FPC for the thinness and lightness. Use FPC for its high-performance electrical properties.

Remember, FPCs are not just for bending anymore.

Dale Wesselmann is a product marketing manager at MFLEX (mflex.com); This email address is being protected from spambots. You need JavaScript enabled to view it.. His column runs bimonthly.