The New IPC-2152

Published: 01 July 2009

by Michael Jouppi

The Current Carrying Capacity in Printed Board Design specification helps designers determine temperature rise in circuits resulting from applied current.

IPC-2152, Current Carrying Capacity in Printed Board Design, is a new IPC standard that replaces the existing conductor-sizing charts in IPC-2221. PCB designers use these charts when sizing conductors to evaluate the temperature rise associated with the size of a conductor and the current running through it.The importance of the new standard is that it gives designers actual data, in the form of charts, which they are already familiar with. The standard is presented in two parts, a main document with basic information and an appendix with detailed information that allows PCB designers to push the limits on specific designs.

IPC-2152 was 10 years in the making, with test vehicle experiments in air and vacuum, thermal analysis of those test vehicles and correlating computer models with the test data part of the work that went into its creation. Test vehicle experiments in air and vacuum, thermal analysis of those test vehicles, and correlating computer models with the test data are a part of the work that went into the creation of the IPC-2152. Some of those variables are board material, board thickness, board size (length and width), environment (air vs. vacuum) and copper planes, as well as effects on conductor temperature rise with respect to altitude and humidity.

There were several significant discoveries that resulted from the development of this new standard. One is an understanding of the historical Internal and External conductor-sizing charts. Testing has shown that the internal conductors and external conductors experience close to the same temperature rise for a given conductor size and applied current. The historical internal conductor-sizing chart in IPC-2221, which is the same chart in previous United States military standards, was not based on testing internal PCB conductors. The significance of this discovery is that when pushing design limits using the new charts, a temperature rise of 100o C, calculated using the historical internal chart, can be shown to be only a 10o C rise. This temperature reduction does not come without a price, an understanding of parallel conductors and power dissipated in the conductors is required to make this type of decision using the new standard.

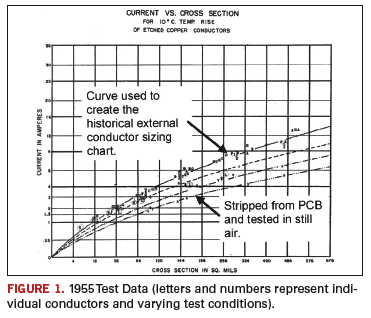

In addition, when evaluating the historical internal conductor-sizing chart, there are two interesting comparisons that can be made using information in the IPC-2152 appendix. One is that the internal chart predicts half the current level that is defined for the same size conductor using the historical external chart. The other comparison, which I find the most interesting, is between the internal conductor chart and test data from the 1955 data used to create the historical external conductor sizing chart. The historical test data shows a set of curves that represent a conductor stripped from the PCB and tested alone in still air, FIGURE 1.

The curve defined by conductors tested in still air, Figure 1, is similar to the internal conductor-sizing chart, on the 10o C curve. Actual internal conductors are shown to operate at lower temperatures than external conductors for the same current and conductor size.

The impact of operating in air or vacuum environments, the influence of copper planes and the myth that internal conductors run hotter than externals is resolved. These items and others are all included in IPC-2152 and the IPC-2152 appendix.

There are other areas that will be added to the new standard over time. A few of those areas are transient current pulses, fusing current, HDI boards smaller than 3 inch by 3 inch, materials other than FR-4 and polyimide and other conductor materials such as inks.

In the meantime, there is a significant amount of information in IPC-2152 that will take time to study before users can comfortably optimize their designs; the good news is that it exists. PCD&F

Michael R. Jouppi is a mechanical engineer specialized in electronics heat transfer and task group chair for the IPC-2152; This email address is being protected from spambots. You need JavaScript enabled to view it. .