Drilling of PCBs - an Overview

Published: 05 June 2008

by Todd Lizotte, Gabor Kardos and Ronald D. Schaeffer

Engineering advances have increase throughput and enabled smaller via sizes with increased process reliability.

As a laser processing service provider, our shop has worked with many industries and seen many applications over the last decade. Laser drills are well established in the field of microvia formation, having taken over for mechanical drills as via diameters have gotten smaller.The drilling of vias in printed circuit boards has been a topic of discussion for many years. Mechanical drilling has been done since the start of the PCB industry, and in the last ten years, lasers have taken over in a number of the high end applications, although mechanical drilling technology has also advanced during that time.

As little as eight years ago, you could still go on the IPC show and find at least a dozen companies promoting laser microvia and mechanical drills. At present, at least in the U.S. market, the field has largely been narrowed down to just a few players, with only Excellon and Hitachi offering both mechanical and laser (CO2 and UV based) Hitachi leads the market in both the U.S. and abroad, so most of the specifications and examples shown are taken from Hitachi.

To keep a leadership position within the marketplace requires the continuous development of new product lines, as well as enhancements to existing products, as the microelectronics packaging and PCB markets shift to continuously higher densities and precise tolerances.

The latest products entering the U.S. marketplace include flexible modular systems that allow for simultaneous drilling of different jobs using a single CNC controller, which provides flexibility in high precision and small lot PCB production. Current models offer industry leading accuracy and speed, outfitted with vision systems, and so are capable of achieving high aspect ratio drilling with front to back alignment.

For high volume applications, there are six spindle drilling platforms designed for high throughput production that maintain high accuracy and reliability in multi-shift operations. Depending on process requirements, the customer can select their drilling systems to be outfitted with spindle speeds ranging from 125,000 to 300,000 RPM, with higher speeds targeted towards micro-hole drilling down to 0.100 mm. In general, mechanical drills are the choice for any vias over 0.250 mm, and while they can be used down to 0.100 mm, (actually, we have seen mechanical drills that can create 0.050 mm vias!), in this range, lasers may be a better choice depending on the application. For vias smaller than 0.100 mm, better results are obtained using laser drills. It should also be noted that mechanical drilling technology has advanced in the area of blind hole drilling. Figure 1 shows 0.050 mm mechanically drilled holes using 250,000 RPM spindles in BT material. The holes are on 200-micron pitch and the photograph was taken after 2000 holes had been drilled.

Within the U.S., the retooling of production drilling equipment has demonstrated significant increased production capacity. Specifically, at a recent install of an ND-6N series system, the first production run averaged in excess of 300 holes/minute including tool changes. Further efficiency has been gained by the ability of systems to be seamlessly integrated into existing drill and job setup automation and networking software.

Because customers require increased precision and throughput, industry leading solutions in both mechanical and in laser microvia drilling technology are constantly being developed. Many of the advancements in the field of laser microvia drilling include extending the capabilities of CO2 lasers to drill smaller microvias, and increasing production throughput by using multiple laser beams using both UV lasers and CO2 lasers.

One of the highest throughput systems is the LU-G series UV laser drilling system with a four beam configuration, two beams per galvanometer. With drilling rates of 2000 holes/second in direct resin, the system is a world-class production tool within the high density microvia marketplace. The system can manufacture microvias with diameters as small as 0.020 mm. Designed to produce precision microvias, the system is outfitted with field tested and proven beam shaping technology. Beam shaping is used to form a flat top laser beam intensity at the target image plane for increased control of wall taper and roundness, enhancing the quality of the microvias produced.

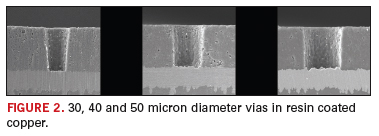

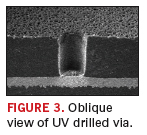

Recently, four panel CO2 laser drilling systems have been manufactured that incorporate multi-panel and multi-beam technology, increasing production capability by nearly 190%. The CO2 laser systems can be applied to either direct drilling applications of dielectric, or to both copper patterning and dielectric removal. In general, UV technology targets vias 0.050 mm or less for direct resin drilling and Cu exposure, while CO2 lasers occupy the ‘middle ground’ between mechanical and UV drilling, used in drilling applications from 0.050 mm to 0.100 mm. Figure 2 shows a row of UV laser drilled vias in resin coated copper, at 30, 40 and 50 microns diameter, respectively. Figure 3 is an oblique angle of a UV laser drilled hole in resin, showing the clean entrance and surface.

In addition to the requirement of picking the correct drilling technique according to desired via diameter, there are also material compatibility issues that must be addressed. Mechanical drills will usually drill any material, but lasers are limited in the materials that they can drill. For instance, CO2 lasers cannot directly drill copper, so UV lasers are used for this material, although Hitachi has pioneered the ‘drilling’ of very thin copper by enhancing absorption on the surface with a sacrificial layer. Normally copper is highly reflective for 10-micron wavelength light, but if a surface altering layer is applied to the copper that allows adsorption, the thin copper can be drilled by the thermal overload. CO2 lasers are also very useful for dielectrics, as the drill rate of CO2 lasers is typically much higher than UV lasers. Also, glass embedded or non-homogeneous materials are usually best drilled with the CO2 laser. One interesting feature of the CO2 laser is that since copper reflects the laser light, it is a self-limiting process when drilling through dielectric and down to a layer of copper. In the case of a UV laser, much more care must be taken to assure that the bottom copper layer is not blown right through. A fundamental consideration for drilling any material is that the material must absorb the wavelength of light being used, as any transparency or reflection will not allow the light to couple into the material.

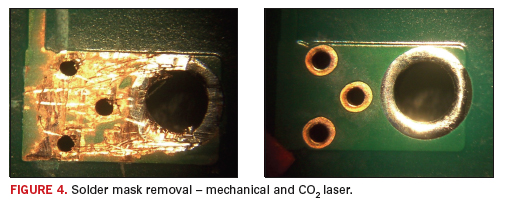

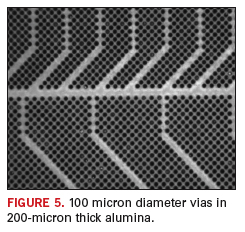

Lasers can be used for many other applications other than drilling vias. These include dielectric material removal for contact points, solder mask removal, the drilling of other materials such as alumina, metals, etc. The flexibility of lasers makes them extremely useful, especially for small lot runs. Figure 4 shows a solder mask removal application. The left side shows a customer’s attempt to mechanically remove the solder mask using a Dremel tool, while the right side shows CO2 laser removal of the mask. Figure 5 shows a dense array of 100-micron holes in 200-microns thick alumina.

In conclusion, while there have been no recent major technological breakthroughs in the drilling of vias, there have been quite a few engineering advances that have increased throughput, enabled drilling smaller via sizes and increased drill reliability in the field. For the foreseeable future, both mechanical and laser drilling will continue to be used as complementary processes, with the choice of techniques depending on many of the factors discussed above. PCD&F

Gabor Kardos and Ronald Schaeffer are with PhotoMachining, Inc. They can be reached at This email address is being protected from spambots. You need JavaScript enabled to view it. and This email address is being protected from spambots. You need JavaScript enabled to view it., respectively. Todd Lizotte is US Director of Emerging Technology for Hitachi Via Mechanics, Londonderry, NH and can be reached at This email address is being protected from spambots. You need JavaScript enabled to view it..