Laser Direct Imaging Made Easy

With over 400 installations worldwide, LDI is gaining global market acceptance.

Laser direct imaging (LDI) technology for PCB applications is over

30 years old, yet, it is less than a decade since the technology became

a production proven tool. Today, there are over 400 units installed

worldwide. The reasons why it took so long to develop this installed

user base are many and varied, including technical hurdles such as

laser technology itself, computing power, availability of dry film /

liquid resists, optics, the art of combining these technologies, as

well as cost and the ability to support customers.

During

that time, many articles were written and presentations made on all the

wonderful benefits LDI brings to the PCB manufacturing process, such as

no photo-tool printing, faster turnaround for small jobs, tighter

accuracy, dynamic scaling functions, and high depth-of-focus.

There

is another side of the LDI that is often overlooked; that is, the

simplicity of the LDI solution. To penetrate the imaging market, the

suppliers of LDI equipment have developed a series of features that

enable both performance to specifications, and ease of use. Using the

feedback from numerous LDI customers, the systems have been improved.

The features of LDI equipment today make it an easier option for a PCB

manufacturer to implement, and because the process is digital, it is

easier to use than conventional imaging ever will be.

Once

the LDI users realized the advantages and potential for the technology,

they challenged LDI suppliers with requests and ideas that, in essence,

established the basis for process improvements.

What makes an LDI system easy to use? There are 4 groups of features that highlight the LDI’s general ease-of-use. They are:

- Process compatibility. LDI fits into your current process with minimal or no changes

- User interface. LDI allows you to be up and running in minimal time

- Image registration. LDI is compatible with many different target types

- Process feedback. LDI provides instant feedback on registration and other useful statistical data

Process Compatibility

UV-based

LDI systems will work with the same conventional resists as do

conventional exposure systems. The entire process has become simplified

through the removal of the photo-tool. Other than that, no change is

required. There are also faster, more sensitive LDI resists available

that can be used. The choice is left with the users based on their

process requirements and resist cost targets.

The

beauty of a digital system is that almost any combination of scaling

can be implemented. The options run the gamut from fixed scaling

(similar to contact exposure, where only one scaling factor is used for

the whole batch), through iterative, corrective mechanisms (where the

optimum scaling is converged upon, as the batch is being printed), to

global scaling systems (where each panel receives the best scaling

factor applicable to that particular panel).

Both

primary imaging and solder mask can be imaged using the LDI system.

There are several companies who have introduced faster solder resist

inks to the market in the past two years. This choice would be optimal

from the point of view of scaling accuracy, but some PCB fabricators

may be reluctant to introduce the LDI in the solder mask area, either

because it involves another equipment purchase, or because they need

their customer’s approval to make a material change.

Until

LDI is used in the solder mask area, the PCB fabricator can continue to

use the LDI for inner and outer layer imaging, even with global

scaling. Since you cannot have one photo-tool for each individual

panel, the next best solution is to use the minimal number of

photo-tools for the solder mask process, and still keep the design

specification on the annular ring.

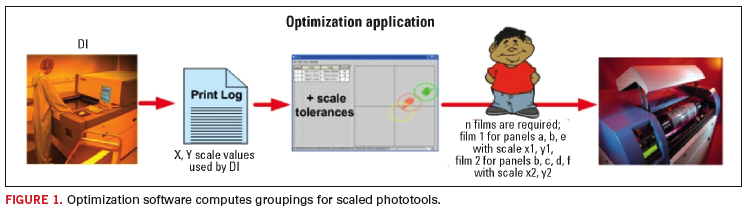

There is special

optimization software that allows you to compute the minimum number of

groups that can be used to divide panels, allowing you to keep the

desired annular ring accuracy. Shown in Figure 1, the process is outlined below.

1.

The outer layer is exposed using LDI with global scaling. The scaling

factor used for the imaging of each panel is recorded in the log of the

LDI system.

2. After the outer layer process is finished and the

next (solder mask or conformal mask) process begins, the system log,

which includes the X- and Y-scaling factors for each panel, is fed into

the optimization application. In addition, the desired annular ring, or

hole-to-pad misalignment, is input into the application.

3. The optimization software tool then calculates:

- The number of films that should be prepared for plotting, for the next (solder mask or conformal mask) stage

- The scale factors for each individual film

- The sorting of panels to their specific group (or photo-tool).

The

user can then sort the panels into the number of groups (or

photo-tools) given by the optimization application, and continue with

the solder mask (or other post-process) stage with the desired accuracy

using the minimum number of photo-tools. If the PCB fabricator uses

serial number stamps, they will be able to sort panel groups according

to the stamp.

4. Since the scaling factors are

already known, there is no need to measure the panels again in order to

get the correct scaling factor for the plotter. This saves additional

time, and reduces process complexity.

5. The LDI

system can also be used to image the scaled data on a UV film, thus

saving several process steps. This is not a primary LDI use, but in a

few cases it could help get the best photo-tool in the first shot.

The

same software can be used for conformal mask before the mechanical

drilling step. All of the previously listed benefits holds true for the

conformal mask step as well. If the customer employs conformal mask

printing using the LDI, then the optimization application will generate

the optimal number of scaling factors to be used in the mechanical

drilling step.

Not only is LDI compatible with your

existing process, it can also be used to improve the process. There is

a vast amount of imaging data stored on the LDI system that can be used

to make improvements in other manufacturing processes.

User Interface

Using

customer feedback has allowed for the improvement of the user interface

to the point where ease-of-use alone has become a valid reason for

using LDI in the PCB fabrication process.

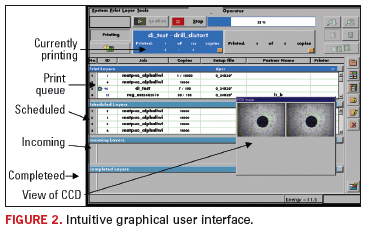

There is an intuitive graphical user interface, simple to operate and learn. An example is shown in Figure 2.

The short learning curve for the equipment is seen as a necessary

attribute. There is a strong focus on simple operational use. You can

have full control of multiple LDI systems on a single display. This

also allows fast and easy recall of previous fabrication work.

The user interface has been designed for a quick and easy setup of new work. It is only a matter of minutes to go from the CAM data to the start of imaging. Since job preparation is done in parallel to production, it allows for high system utilization. Only minimal inputs are required from the operator (e.g. panel thickness and energy in mJ/cm2) but it is also very easy to change working parameters directly on the screen.

The user interface also allows flexibility on

how panel sides are imaged, either side A followed by side B for each

panel (ABAB), or all the “side As” first, followed by “side Bs” (AABB).

All these functions can also be controlled from an off-line

application, outside of the yellow room environment.

Image Registration

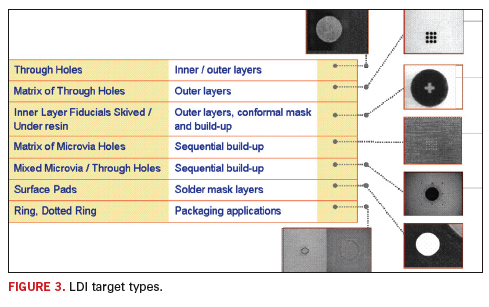

For

image registration, the LDI system relies on acquiring target images on

the panel. This real time image acquisition and analysis process is

crucial for registration. Some LDI systems are compatible with a large

number of different target types, and have the capability to define and

add as many targets as you like. The types of targets that LDI must be

able to incorporate are shown in Figure 3. These

targets include, through holes, matrix of through holes, innerlayer

fiducials skived /under resin, matrix of microvia holes, mixed microvia

/ through holes, surface pads, ring/dotted ring – all covered or not

covered by resist.

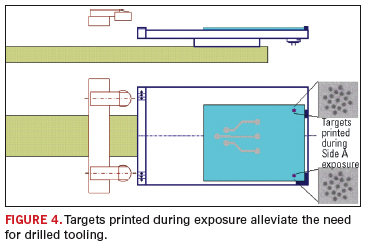

Some LDI systems use a UV marker to create targets on one side of an inner layer (Figure 4),

thereby avoiding the need for drilling through holes, which is an

additional undesirable process step. As one side of the innerlayer is

being printed, two UV marks are printed on the underside as well. When

the layer is turned over, those two UV marks are then used to achieve

accurate (or “the most accurate”) side-to-side registration.

Process Feedback

An

important aspect of every digital printing process is the availability

of instant feedback for the user. The quick manner in which data is

converted to imaged pattern must be accompanied by safeguards in the

form of alerts. For example, if the panel is badly distorted and the

dynamic scaling option suggests a value beyond the set limits, an alert

should appear. Another confidence building feature is the registration

feedback, essentially showing the operator the expected front-to-back

registration for the imaged panel.

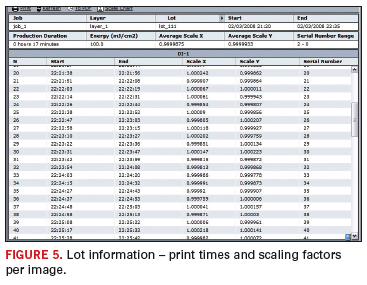

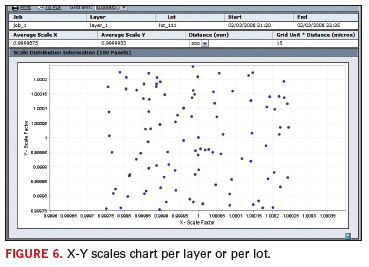

In addition to

instant feedback, data can be generated from the LDI system’s vast

database of imaging history for review by supervisors and managers.

Since every image’s parameters are stored in the system, many

statistical charts can be easily and quickly extracted. These include

panels imaged over a specific period of time, panels per shift,

potential vs. actual panels per day, printed panels per energy setting

(mJ/cm2), system utilization (hours/day), average batch

size, panel size distribution, and much more. All of this information

can be accessed and customized for each PCB fabricator’s needs. This is

an example of the power of digital printing. The two examples, Figure 5 and Figure 6, show scaling data with respect to a particular batch.

Summary

In

the last few years we have witnessed the introduction of many new LDI

capabilities and uses. It is our prediction that LDI technology will

continue to proliferate. In addition to higher LDI speeds and increased

accuracy, there has also been an improvement in the cost of ownership.

New LDI capabilities are being developed, such as real time analysis,

advanced alert mechanism, on-line inspection and enhanced real time

feedback. The trend is a focus on improvements to productivity. It is

up to the many users of LDI to share their experiences with suppliers

and engage them in the development of future solutions. PCD&F

Guy Alon is the director of PCB marketing for Orbotech Inc; This email address is being protected from spambots. You need JavaScript enabled to view it.. Ralph Birnbaum, PhD is the LDI marketing manager of the PCB Division in Orbotech Ltd; This email address is being protected from spambots. You need JavaScript enabled to view it..