Improved Innerlayer Bonding for Sequential Lamination

Multiple lamination cycles add cumulative thermal stress to the innerlayer bonds.

Industry requirements to meet the demands of lead-free applications

have challenged many areas of PCB fabrication and design. These demands

have initiated a rapid influx of new dielectric materials, which,

despite increased thermal stress, must remain effectively bonded to

copper innerlayers. Delamination failures in advanced multilayer and

sequential-build products, caused by the conversion to lead-free

soldering, have also driven the need for improved oxide replacement

technology.

Such products must resist higher peak

temperatures, some 30°C greater than eutectic applications. Based on

statistically designed experiments, a new process has been developed

that delivers a more resilient copper conversion coating. The process

has shown improved bonding performance and greater stability at higher

temperatures, thus improving its capability for more thermal excursions

(assembly-reflow cycles at >260°C) without failure. This article

focuses on the product development criteria and performance evaluation

required to develop a process that is suitable for this challenging

environment. The testing and qualification will include data on peel

strength, solder float and IR-reflow testing.

Over

the past decade, traditional alkaline black oxide (or brown oxide)

bonding processes needed replacement due to a range of technical and

environmental issues as well as heightened cost pressures. The acidic

peroxide-sulfuric (oxide-replacement) processes quickly found favor due

to lower cost and more environmentally friendly chemistry. These

peroxide-sulfuric technologies, which use a primary organic additive to

enhance the surface texturing, were shown to deliver excellent bond

integrity in the pre-RoHS assembly setting.

However,

it comes as no surprise that continuing advances in PCB fabrication are

now pushing the performance requirements of these processes as well.

These include:

- Advanced board constructions / sequential lamination / microvia capable build-up processes

- New halogen free, high Tg and filled phenolic cured dielectric materials

- Demanding, high temperature lead-free assembly conditions

The Challenges

The

current peroxide-sulfuric oxide replacement process work based on a

“controlled etch” mechanism that typically removes 45 to 75 microinches

(1.1 to 1.9 μm) of copper. Innerlayers are first cleaned and then

conditioned in an alkaline medium, rinsed, and then are processed in

the peroxide-sulfuric micro-etching bath. The copper saturation

capacity of this bath is limited and has historically been on the order

of 18 to 22 g/L. Over the past three years, this technology has

improved, allowing a higher solution capacity of 50 g/L in high-volume

production environments. This capacity increase has been largely the

result of improved copper solubility coupled with greater process

stability.

The requirements for the high-yield

production of controlled impedance and fine line innerlayers also call

for further reductions in the copper etch levels. This low etch

approach greatly benefits high frequency signal integrity by

significantly reducing the “skin-effect” caused by a deep etch profile.

Reduced etching is often at odds with improved bond performance. The

need to improve bonding performance to meet the demands of new resin

systems and RoHS assembly temperatures, with minimal removal in the

order of 35 to 45 microinches (0.9 to 1.1 μm) of copper, has become a

benchmark for a “best in class” process.

Within

this challenge, higher values for peel strength and increased T260 and

T288 (time-to-delamination) values are continually sought, with the

process undergoing continuous review in order to deliver even greater

performance. This improvement is needed to meet the requirements

associated with the sequential lamination cycles applied in some

build-up processes, and to withstand the extreme thermal stresses

incurred in lead-free assembly and re-work.

The Oxide Replacement Process

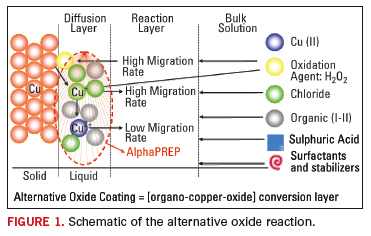

The

peroxide-sulfuric oxide replacement process is controlled by a primary

organic material that modifies the etching mechanism to provide a

consistent, highly textured, and characteristic surface structure. Not

only does the primary organic additive accelerate the etch and modify

the copper surface, but it also chemically combines with the copper to

produce the characteristic organo-copper coating. This organic coating

is based mainly on cuprous (Cu+) oxide but also contains some cupric

(Cu+2) oxide. These give the conversion coating its characteristic

red-brown color. The schematic formation of the alternative oxide

coating is shown in Figure 1.

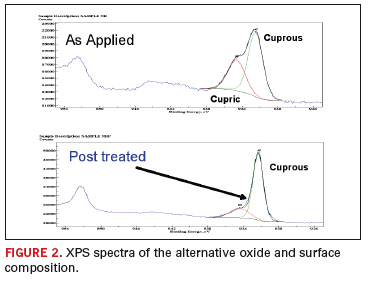

It

is well understood that a cuprous-rich oxide coating typically delivers

higher bond strength in the prepreg to copper layer. Cuprous oxide is

more thermally stable than cupric oxide. In addition, a cuprous rich

oxide has a higher chemical resistance to PTH chemistries, which can

give rise to “pink ring” through the attack and separation of the oxide

planes around the periphery of the holes. This chemical resistance is

critical not only for the metallization of high aspect ratio

through-holes, but more importantly for the landing pads on blind

microvias. It is possible to post treat the oxide conversion coating

using an alkaline process to remove the less resistant cupric oxide.

Such post treatment can increase the peel strength of the coating by 10

to 15%, but it does not improve the resistance to thermal delamination.

The elemental analysis is shown for both a standard and a post-treated coating. Figure 2

shows the actual XPS spectra of the as-produced coating and

post-treated coating (following a proprietary post dip). As would be

expected, the post-treated layers have a lighter more-reddish

appearance, indicative of the increased cuprous oxide content. This

coating composition is also outlined in Table 1.

The Effect of Sequential Build

Increasingly,

PCB construction, especially for thin card mobile or PDA-type products,

is produced using sequential lamination techniques. Here, each

lamination cycle adds additional and cumulative thermal stress to the

innerlayer bond within the core construction. Depending on the

lamination temperature, (typically 190 to 200°C), this can

progressively reduce bond strength prior to final soldering, hence

increasing requirements for improved thermal integrity. The negative

impact on peel strength caused by sequential bonding cycles is shown in

Figure 3.

The

discussion of the repeated thermal cycles used in SBU fabrication must

include consideration of the added effects of the higher temperatures

seen in lead-free assembly. Exposure to multiple thermal cycles can

have a cumulative effect on bond integrity.

Impact of Lead-Free Assembly on the Alternative Oxide Bond

The

IR reflow soldering cycles used in assembly apply a large amount of

stress to both the core and sequential build layers. Although the peak

temperatures are targeted at 245 to 250°C, they can clearly overshoot

these values, potentially rising to 260°C or more. At this point, or

during the subsequent solder-wave application, the boards can fail due

to delamination. Large copper areas, especially those carrying very

high cluster-densities of small holes, can be especially vulnerable.

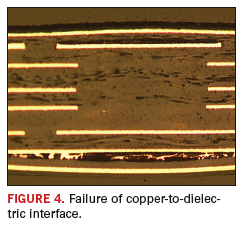

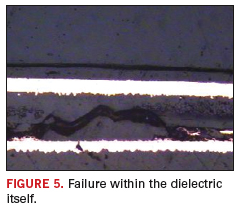

Delamination

can be triggered by a combination of many factors, and the first step

in determining root cause is to answer the key question – where is the

delamination occurring? The problem is typically diagnosed by using

cross section techniques to determine if the breakdown is between the

copper-to-dielectric layer (adhesive failure), or within the dielectric

itself (cohesive failure). Examples of these two conditions are shown

in Figure 4 and Figure 5, respectively.

Product Improvement Approach

Following

the transition to lead-free, the development group had already

completed work designed to provide alternative oxide products with

improved high temperature performance. An older, first generation, 25

g/L low copper capacity product (LCC) with improved thermal

stabilization was used as the benchmark. This LCC prototype product had

a demonstrated capability to withstand extended IR lead-free reflow

cycles, and was developed specifically for critical high-end

applications. For comparison, a 50 g/L high copper capacity (HCC)/low

etch product was used to address the requirements of higher signal

integrity, improved environmental capability (reduced waste), and lower

cost of ownership.

The HCC technology used organic

stabilization similar to the LCC product and had an already

demonstrated better performance for peel strength and thermal shock

resistance in high volume production environments. The defined approach

was to further optimize the HCC technology through more exhaustive

thermal stability testing, by using extensive L9 and L18 Taguchi

methodology.

To test the product improvements against the benchmark, a rigorous testing protocol was developed. It included a test vehicle (Figure 6)

that was based on a six-layer board with a rigid FR-4 based four-layer

core. The FR-4 material was standard 150°C Tg epoxy. To simulate a

sequential build-up product, resin coated copper was added as

additional layers (one and six) to the four-layer core. Prior to

lamination of the resin coated copper foil, the core layers two and

five were electroplated with a standard acid copper process to simulate

a buried via construction. This build allowed the examination of the

effects of in-house electroplated copper on bond strength.

During

the testing process the test vehicles were subjected to high stress

thermal excursions of 270 to 280°C in an IR reflow chamber. The

failures that occurred could be found in either the central core or

within the surface layers. The profile of the IR reflow excursion is

shown in Figure 7.

Initial Benchmarking Fesults

Using

the IR profile described, copper innerlayers treated with the HCC

process were subjected to the reflow cycle. Where older generation

technology showed significant color change and pronounced thermal

breakdown effect at temperatures over 260°C, the HCC process was able

to withstand the peak of 270°C without any pronounced change of color.

In

addition, Auger studies were used to determine the effects of

temperature on the organo-coating. The Auger tests showed no

significant loss (evaluating the elements Carbon and Nitrogen) or

oxidation of the coating. Further, significant improvements in

stability were seen over the lower soldering temperature range. No

perceptible change or evidence of oxidation was experienced. The Auger

results are shown in Figure 8.

The

improved HCC technology also demonstrated a 6 to 15% improvement in

peel strength of the coated layers. These results represent a major

step forward in improving the coating’s thermal resistance.

Furthermore, at 270°C the HCC technology was able to withstand an

average of 1.5 additional cycles before failure due to delamination

compared to the first generation processes.

Having

achieved very satisfactory improvement with the high copper capacity

formulation, the next step was to optimize the formula for thermal

performance using the Taguchi approaches previously described.

The

applied series of test arrays included a) the primary and secondary

inorganic acids (that influence the etching characteristic and

solubilize the copper); b) the organic components (that drive the

modified etch reaction rate, produce the organo conversion coating, and

stabilize the process and the coating); c) the grain refiner

(essentially a chloride based species), and finally; d) the oxidizing

agent – hydrogen peroxide (also drives the reaction-rate and texture

depth).

The studied responses were coating color,

etch-rate, pull/peel strength after coating, and most importantly, the

resistance to delamination using multiple IR reflow cycles with peak

temperatures of 270°C and 280°C respectively.

Details of some of the individual component plots, drawn from one of the later L18 arrays employed, are illustrated in Figure 9.

As

expected, varying levels of response, and some interactions, were seen

with many of the parameters employed. The findings were interesting for

several reasons. It was determined that only one organic additive

parameter significantly affected the color of the coating, but several

of the additives had a significant influence on the delamination

resistance. By contrast, the peel strength was mainly impacted by two

significant factors.

Interestingly, all the factors

that positively influenced the thermal performance also improved the

primary peel strength results. These factors also contributed to a good

aesthetic coating color and appearance. This can be seen in the

similarity of the displayed Taguchi responses that moved largely in

unison. This facilitated the completion of an optimized HCC product for

the confirmation runs. A summary of the Taguchi optimization is shown

in Table 3.

The

confirmation testing showed an expected and very positive gain with the

achievement of more than 10 IR reflow cycles without failure, based on

the aggressive test vehicle and profiles involved. The resulting

confirmation runs for delamination, as compared to the first generation

technology and HCC standard benchmarks are shown in Figure 10.

Conclusions

The

work described in this article has encompassed a long period of design,

development and testing, and was carried out over a three-year period.

Along the way, a lot of input has been received from the market, in

terms of both defining the challenge and applying best practices to

meet the growing industry requirement for improved PCB thermal

resilience.

Several leading PCB fabricators have

made significant progress in selecting improved materials and

incorporating better lamination and process procedures, all of which

open up the operating window for more demanding products. From this

work, it is clear that many factors can significantly and adversely

outweigh the alternative oxide contribution in achieving the balance

required for bullet-proof performance.

To play its

part, this study has been focused solely on finding ways to improve the

performance and contribution of the alternative oxide bonding

technology. The goal has been to provide a robust process with a wider

operating window offering better thermal resilience.

Conclusions

from this specific study can be summarized as follows. Delamination

failures due to lead-free thermal stress can be caused by many factors,

most significantly those involving the dielectric materials and the

lamination process. In the broader context, industry opinion is that

the alternative oxide process has a smaller impact than other material

factors in delamination. Improving the process can, however, make an

important contribution, especially for PCBs with large

copper-to-dielectric bonding areas such as internal ground planes.

This

can be seen with the older generation alternative oxide bonding

technology, which cannot consistently meet the increasing industry

requirement of highly advanced and performance sensitive designs for IR

reflows without blistering, delamination or related electrical failure

in lead free applications. The stability of the respective

organo-metallic conversion coating diminishes at 260°C, where bonding

performance decreases with each successive thermal excursion, leading

to potential delamination issues.

The use of

proprietary post treatments, which increase the cuprous oxide ratio can

provide improvements to peel strength, but do not necessarily solve the

thermal resilience challenge. One conclusion that can be drawn from

this work is that the industry-standard pull/peel strength measure

cannot adequately predict in-process bond strength, or a PCB’s

resistance to delamination under thermal stress.

Improved

LCC (low copper capacity) and HCC (high copper capacity) products have

already demonstrated higher thermal stability than their earlier

counterparts, along with greater capability to withstand multiple

lead-free reflows at inflated peak IR reflow temperatures of 270 to

280°C.

The laboratory work described in this article

establishes that an optimized HCC process can also more effectively

meet the 10 plus multiple reflow requirements associated with

sequential lamination and RoHS assembly simulation. Product design

specifications for a low-etch attribute (1.0 to 1.2 μm) for controlled

impedance, fine line integrity and improved high frequency signal

integrity have been key factors in this work. Maintaining the required

high copper capacity of 50 g/L delivers reduced environmental impact

and the lowest cost of ownership. PCD&F

Dr. Abayomi I. Owei is president/principal research scientist at Avo Tech International Inc.; This email address is being protected from spambots. You need JavaScript enabled to view it.. Dr. Jean Rasmussen is R&D manager, PWB metallization, at Enthone; This email address is being protected from spambots. You need JavaScript enabled to view it.. Dr. Axel Dombert is European technical manager, PWB products, at Enthone; This email address is being protected from spambots. You need JavaScript enabled to view it.. Danis Isik is a research scientist, PWB products, at Enthone; This email address is being protected from spambots. You need JavaScript enabled to view it.. David Ormerod is business director, PWB metallization, at Enthone; This email address is being protected from spambots. You need JavaScript enabled to view it..