PCB Database Viewing for SI Analyses, Parts 1 and 2

Signal integrity modeling, simulation and measurements can demand frequent examination of PCB databases.

This article ran in two parts in the August and October issues. Both parts are included here.

During

high-speed PCB design, the need frequently arises to view the PCB

database for signal integrity objectives; for instance, to ensure the

widths and lengths of routed traces are consistent with routing

guidelines (constraints) generated via simulations. It can also prove

beneficial to inspect the PCB prior to extracting the database for

post-route simulations. Another occasion that necessitates careful

database viewing is for identifying locations and net names of PCB test

points for laboratory probing and measurements after board fabrication.

A high-speed digital design team1

may include specialists in different fields such as logic design,

product design, signal integrity, EMI, mechanical engineering and PCB

design. Such a diverse and complex design environment creates the need

for the SI engineer to regularly examine the PCB database at different

stages (i.e., when the board is partly routed, completely routed or

after fabrication).

The PCB database examples in this

column employ Cadence Allegro design software, but the signal integrity

concepts apply to boards produced with other PCB programs. Williams2

is a good reference. It presents a listing of numerous PCB design

programs. Williams uses CadSoft Eagle software for several reasons,

including availability of a useful free version, relatively inexpensive

upgrades, a comprehensive library, and Windows or Linux capability.

When

selecting a PCB design package, ensure that the software can output

Gerber files (hence, avoid programs that output only to proprietary

formats or require use of a particular PCB fabricator), has

extensive/expandable part library, and an efficient autorouter feature

(for instance, a rip up/retry router can perform well, whereas a grid

router type is usually less effective2).

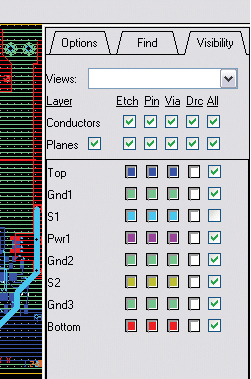

Some useful information obtainable when viewing a PCB database are the stackup layer names. Figure 1 displays the name of each layer for an eight-layer board examined with the Allegro Free Physical Viewer.

|

|

Let

us briefly consider the application and significance of layer names and

PCB stackup in producing accurate board simulations. A modern approach

to high-speed PCB design involves extensive use of EDA tools1,

modeling and simulation. One such tool is Mentor’s XTK. XTK simulations

require creation of numerous files, one of which is the Global Control

File (.GCF). It is composed of several sections: Design, Defaults,

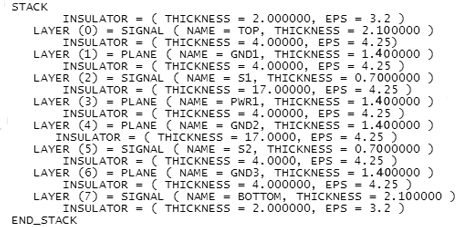

Control, Constants, Files, and Stack3. Figure 2 shows

the Stack section of a .GCF file applicable for nominal simulation of

the aforementioned eight-layer board. Stack layer names (i.e., TOP,

GND1, S1, PWR1, GND2, S2, GND3, BOTTOM) in Figure 2 are the same as

layer names in Figure 1. Figure 2 also contains thicknesses for each

layer.

|

|

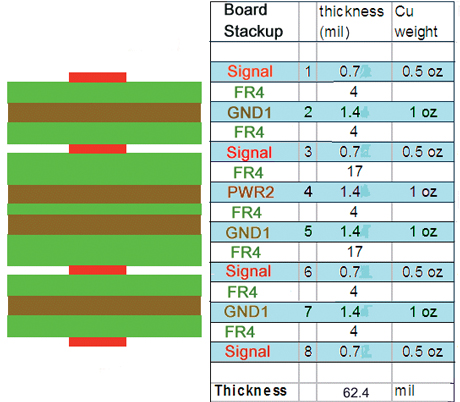

These

layer thickness values needed for accurate XTK simulations are usually

obtained from the board stackup diagram (or spreadsheet) as illustrated

by Figure 3. Here, thickness of top and bottom

(outer) layers are given as 0.70 mil (0.5 oz), which represent values

before plating. The thickness of outer layers after plating can

increase to ~ 2 mils. The (total) PCB thickness is about 62 mils, a

standard value. Other standard PCB thicknesses are 39, 93 and 125 mils.

PCB stackups are typically constructed by alternating layers of prepreg

and core. Prepreg is uncured fiberglass-epoxy resin, which becomes

cured (hardened) when heated and pressed. The core is a thin piece of

dielectric (cured fiberglass-epoxy resin) with copper foil bonded on

both sides.

|

|

Regularly,

the need arises to highlight a single-ended line, a differential pair

or a group of nets for various types of inspections. Allegro Free

Viewer allows two ways of highlighting a net: a) temporarily, using the

show element4, and b) permanently via the hilight command, which requires dehilight to be turned off. The shadow mode can be used to make highlighted nets stand out.

For high-speed PCBs, it is often advantageous to specify small trace widths in order to minimize board real estate5

and manufacturing costs. Avoid multiple vias along high-speed nets.

Subsequently, single-ended (or differential) traces are examined for

width, length and number of vias on the net.

A differential pair can be highlighted and inspected for imbalances6

that may cause electromagnetic radiation. The length difference between

traces of a differential pair can demand evaluation, because achieving

length matching (within a specified tolerance, such as 10 mils) can

prove critical for optimum timing margins7, common-mode signal prevention and EMI.

|

|

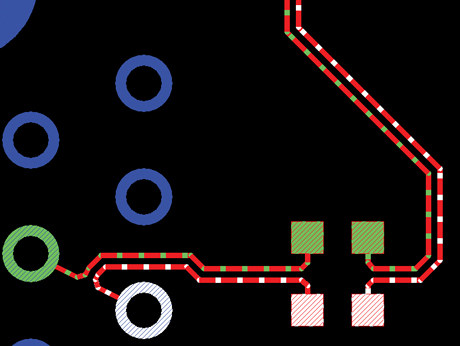

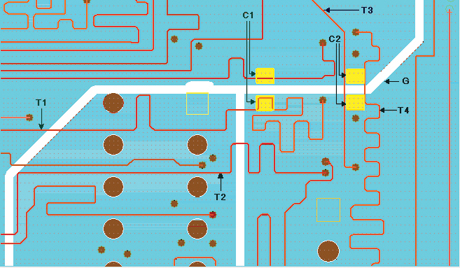

Figure 4 shows a section of a high-speed differential pair, which includes pads for AC coupling capacitors. Some high-speed links such as PCI Express8 have AC coupling capacitors, specify using individual 0603 (or a package with smaller lead inductance) capacitors and avoid the use of capacitor packs (C-packs). Capacitor pads should be implemented symmetrically for both signal lines of the differential pair. When viewing a high-speed PCB database, it is important to ensure that such bus specifications are satisfied.

High-speed differential

pairs, traces traversing reference plane splits, BGA escape regions and

relative routing of adjacent signal layers are frequently inspected for

SI objectives. Differential nets are often closely examined due to

their prevalence and significance in high-speed PCBs. For instance,

they are evaluated for length matching7, and other factors that can cause skew9.

When a differential pair includes termination resistors, DC blocking

capacitors, via pairs or serpentine sections, it needs to be checked

that such elements are implemented symmetrically10,11.

Sometimes a PCB design needs to be inspected for high-speed traces crossing slots12 in a neighboring power/ground plane. An example is illustrated by Figure 5.

It displays several traces close to and routed over splits in the

reference planes. This may cause impedance discontinuities, crosstalk

and other undesirable effects12. Figure 5 also shows

stitching capacitors aimed at reducing the adverse effects associated

with high-speed traces crossing plane cutouts. This PCB database was

evaluated using the Allegro Free Physical Viewer, by turning on the

desired signal layer and its reference plane with other layers turned

off.

|

|

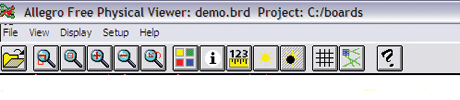

The Allegro viewer can be utilized to open board files having .brd extensions. Its menu and toolbar are depicted by Figure 6.

It contains file Open, several zoom features (such as Zoom Points, Fit,

In, Out, Previous), Color (and visibility), Show Element, Measure,

Hilight, De-hilight, Grid Toggle, Rats Toggle, and Help.

|

|

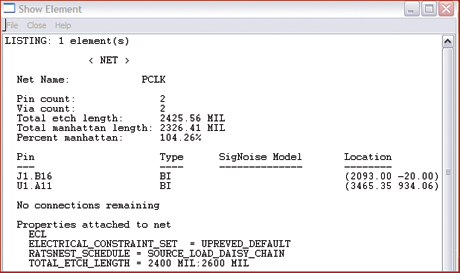

One application of the Show Element feature is to ascertain trace lengths, as illustrated by Figure 7.

The

Show Element window (Figure 7) displays the total etch length, the

percent and the total Manhattan lengths. The Manhattan length defines

the shortest path13 between two ends of the connection if

routed orthogonally. In addition to net length, the Show Element window

can reveal other information such as trace widths and

properties/electrical constraints associated with the net.

|

|

It

needs to be noted, when viewing nets with series components such as a

resistor or a capacitor, that the trace can have sections of different

net names. For instance, a clock line with a driver U1, a series

resistor R1 and a receiver U2, may have a short section (from pin of U1

to one pin of R1) with net name CLK and a long section (from the other

pin of R1 to pin of U2) named CLKR. The CLK and CLKR segment lengths

then need to be added for calculating the total trace length. When

inspecting such multiple sectioned nets, it can also prove beneficial

to review the schematic drawing of the design to gain a more clear

understanding of components and topology.

The

wildcard character (*) of Allegro Viewer can be utilized for various

applications. For instance, it is possible to simultaneously examine a

family of nets and to ascertain the min/max routed lengths for a group

of traces belonging to a bus. The zoom and pan features of this

software can be applied to closely inspect various PCB features

including long nets.

As mentioned in Part 1, the

examples in this column utilize Cadence Allegro; however, similar

inspections and SI evaluations are feasible on databases produced by

other PCB design programs.

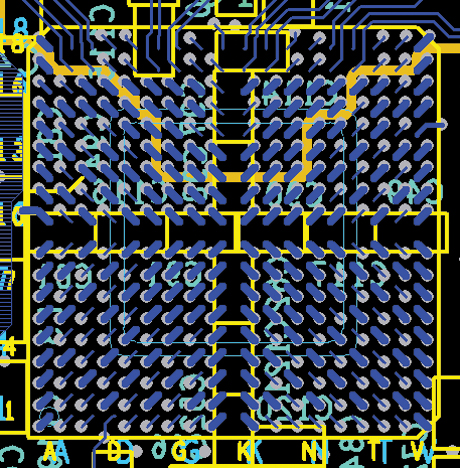

Several features of BGA breakout as depicted by Figure 8

deserve appraisal. Connections between differential pairs and BGA

balls, the necking down of traces, which can cause impedance

discontinuities, and power delivery to the chip usually demand

inspection.

|

|

It

is desirable that traces routed between neighboring pins (or vias) be

properly centered and to avoid routing over plane splits (and other

plane voids such as anti-pads) whenever feasible.

BGA escape regions often routed in a radial14

fashion (out from the center of the land array) can produce a

horizontal and a vertical slot useful for placing surface-mount

decoupling capacitors on the bottom layer. It also allows superior

power feed (wider power channel) to the BGA.

It is often necessary to identify test or access points for oscilloscope probing and signal measurements. Some standard1

SI measurements include: rise/fall times, propagation delay, noise

margin, timing budget, overshoot/undershoot, and crosstalk. A suitable

access point for probing is often on the bottom layer underneath the

BGA at a dog-bone via. A ground close to the signal pin is also needed

for probing to minimize ground loops and associated inductive noise

when applying oscilloscope probes15.

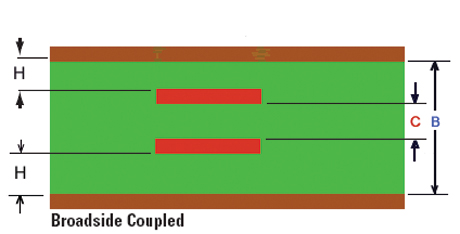

When the PCB stackup includes two adjacent signal layers such as dual (or broad-side-coupled) stripline structure as shown in Figure 9, it is sometimes necessary to evaluate the routing.

|

|

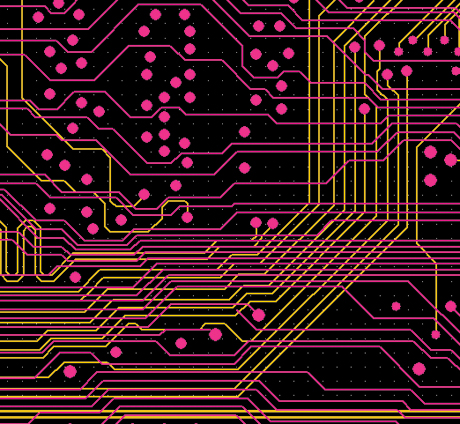

Figure 10

displays numerous nets belonging to two such adjacent inner layers. In

certain regions, the traces of the two layers are routed parallel, and

in other areas, they are orthogonal to each other.

|

|

For high-speed PCBs, it is preferable that signals on adjacent layers16,17

be routed in an orthogonal (90 degree conductor crossing) fashion to

minimize crosstalk. However, coupling would also depend on such factors

as separation distance between the layers, the parallelism length,

driver strength and signal edge rates. It is preferable (for

diminishing crosstalk) to place the signal layers close to the

reference planes, to use thin trace widths, short parallel lengths and

offset the traces. The exact magnitude of crosstalk can be ascertained

via modeling and simulation.

An outstanding resource for exploring additional information related to topics discussed in this column is the Signal Integrity List email reflector (SI-LIST). It is free to subscribe to the SI-LIST and the list archives are available18 for viewing. PCD&F

Dr. Abe (Abbas) Riazi is a senior staff electronic design scientist with ServerWorks (a Broadcom Company). He can be reached at This email address is being protected from spambots. You need JavaScript enabled to view it..

ACKNOWLEDGEMENTS

My gratitude to Richard Kuo, Greg Albers, Peter Arnold , Mark Furnace, and Suresh Vegesna for reviewing the manuscript and furnishing excellent feedback.

REFERENCES

1. Roy G. Leventhal and Lynne Green, “Semiconductor Modeling For Simulating Signal, Power, and Electromagnetic Integrity”, Springer, 2006, pp. 1-7, pp. 526-527.2. Al Williams, Build Your Own Printed Circuit Board, McGraw-Hill, 2004, p. 18, pp. 190-193.

3. Quad Design, Preparing PCB Design Databases for Simulation with TLC/XTK/QUIET, document no. Q3FR018MNL6_5, November 1996, Chapter 5.

4. Cadence, Allegro/APD Design Guide: Getting Started, product version 14.2, 2002, pp. 129-137.

5. Stephen H. Hall, Garrett W. Hall, James A. McCall, High-Speed Digital System Design A Handbook of Interconnect Theory and Design Practices, John Wiley and Sons, Inc., 2000, pp. 37-38.

6. Tom Granberg, Handbook of Digital Techniques for High-Speed Design, Prentice Hall, 2004, p. 711.

7. Abe Riazi, “Length Matching for High-Speed Differential Pairs,” Printed Circuit Design & Manufacture, February 2005, pp. 17-18.

8. PCI Sig, Add-in Card Compliance Checklist for the PCI Express Base 1.1 Specification” Revision 1.1, 2006, p. 17.

9. Bruce Archambeault, “EMI/EMC Concerns for High-Speed Differential Signals,” Printed Circuit Design & Manufacture, July 2007, PP. 16-17.

10. Abe Riazi, “ Differential Signal routing Requirements,” Printed Circuit Design & Manufacture, February 2004, PP. 22-23.

11. Abe Riazi, “ Avoiding Differential Pair Routing Violations,” Printed Circuit Design & Manufacture, August 2004, PP. 26-29.

12. Abe Riazi, “Effects of Plane Splits on High-Speed Signals, Part 1,“ Printed Circuit Design & Manufacture, February 2007, PP. 16-17.

13. Lee W. Ritchey, Right the First Time: A Practical Handbook On High-Speed PCB And System Design, Vol. 1, Speeding Edge, 2003, PP. 222-223.

14. Bernard Voss, “BGA Power Delivery Routing,” Printed Circuit Design, September 2002, P. 33.

15. Peter D. Hiscocks, James Gatson, “Oscilloscope Probes: Theory and Practice,” Syscomp Electronic Design Limited, July 12, 2007.

16. Leonard Dieguez and Salman Jiva, “Altera Gigabit Channel Design Guidelines,” Signal Integrity Net Seminar Series, 2007.

17. Bernard Voss, “Tricks of High-Speed PCB Stack-Up,” Printed Circuit Design, April 2002, P. 18.

18. SI-LIST archives are viewable at freelists.org/archives/si-list. Old (prior to June 6, 2001) archives available at qsl.net/wb6tpu.