The 46th Internepcon Japan electronics trade show was held on Jan. 18-20 at Tokyo Big Sight.

I attended the three-day trade show in hopes of discovering the next electronics breakthrough, and examine the business trends within a shrinking electronics industry. The show attracted a large amount of visitors; about 150,000 people visited over the three days. It was tough navigating between the trade show booths because the aisles were full with people.

It is now common to have related exhibitions held concurrently. For this reason, the exhibition gets bigger each year. Listed below are the events that were held simultaneously:

- 34th ELECTROTEST JAPAN

- 9TH Light-Tech Expo

- 18th PWB EXPO (Printed Wiring Boards Expo)

- 18th IC PACKAGING TECHNOLOGY EXPO

- 18TH ELECTRONIC COMPONENTS & MATERIAL EXPO

- 7TH FINE PROCESS TECHNOLOGY EXPO

- 3RD WEARABLE EXPO (Wearable Device & Technology Expo)

- 1st RoboDex (Robot Development & Application EXPO)

- 9TH CAR-ELE JAPAN (Int’l Automotive Electronics Technology Expo)

- 8th EV Japan (EV & HEV Drive System Technology Expo)

- 7th Automobile Lightweight Technology Expo

- 5th Connected Car Japan

- 3rd CAR-MECHA JAPAN (Automotive Components & Processing Technology Expo)

- 1st SMART FACTORY Expo

More than 2,200 companies and organizations reserved booths. The East Hall expanded the floor space 30% this year to accommodate the new exhibitors. Due to the size of the exhibition, I was not able to review the entire show. In my opinion, the promoter should focus on visitor engagement, and not the head count at the gate.

A big change this year was the increased size reserved for the automobile vendors. More than half the floor space was dedicated to car electronics or related products. Consumer Electronics companies will target the automobile industry during recessionary periods because the automobile industry is more stable than the consumer electronics industry. However, the automobile industry in Japan is more conservative than the consumer industry; therefore, it takes time and money before the sales pitches bear any fruit. Most of these companies will stop peddling to the auto industry once their traditional businesses begin to flow again. Unfortunately, the current recession for consumer electronics is very long, and the Japanese electronics companies have few customer choices other than the automobile market.

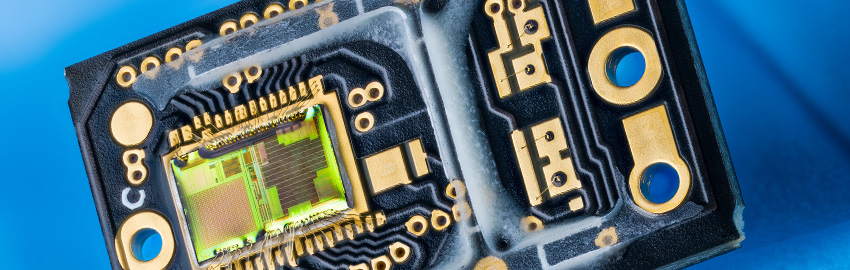

I focused my attention on traditional electronics packaging at the show. The PWB section of the show was smaller this year. Many of the major circuit manufacturers did not reserve booths. Several mid-sized manufacturers introduced upgraded technologies such as over 100 layer counts and MIL certified rigid-flex. FiWLCSP and FoWLCSP are the common technology for IC substrate suppliers. The manufacturers developed finer traces than 10 microns. Specialty chemical suppliers featured competitive solutions for the semi-additive process capable to produces 2 micron traces. I came across several new circuit manufacturers from Taiwan, mainland China and other Asian countries. Usually, their technology and quality levels were subpar compared with Japanese manufacturers; however they are just as good today.

Wearable technology is popular and will continue to be popular in the electronics industry. Flex circuit manufacturer’s featured new technical concepts for stretchable circuits and transparent circuits using new substrate and conductor materials. Textile manufacturers introduced new functional fibers for use as the basic material for wearable electronics. Their demonstrations did garner a lot of attention, but the ideas for application abled products is still in in infancy, and make take a few more years to commercialize.

Companies affiliated with assembling sections were present at the show. Manufacturers for mounting machines and soldering occupied relatively large spaces, but there were fewer companies compared with last year’s show, and most were headquartered in Japan. I was not very sure if these Japanese manufacturers are growing their market share, but I do know that foreign suppliers do not have strong representation in this market. EMS manufacturers had one company headquartered in Japan. They were happy to report their revenue topped over $1 billion due to expansions in China, Vietnam and Mexico (Ed.: UMC Electronics exhibited at InterNepcon Hapan this year.)

Looking at the whole exhibition, I can see that business for the consumer electronics industry in Japan remains sluggish. Many electronics companies are still shaking the bushes looking for new business, especially from the automobile market. It may take some time to get this well primed, but once it does, they will benefit from increased business. I remain optimistic.

Dominique K. Numakura, This email address is being protected from spambots. You need JavaScript enabled to view it.

DKN Research, www.dknresearch.com

DKN Research Newsletter #1701, February 5th, 2017 (English Edition)(Micro Electronics & Packaging) This email address is being protected from spambots. You need JavaScript enabled to view it.

For newsletter archives click here.

Headlines of the Week

1. Murata developed a heat-resistant ceramic capacitor series RHS for modules in engine rooms. It is available at 200C.

2. Panasonic commercialized a new low-loss thin flexible laminate for multi-layer flexible circuits. The bonding sheets can be kept under room temperature.

3. AGC Asahi Glass developed a glass sheet with low CTE for the fan out wafer level package of the next generation semiconductor devices.

4. Ube Eximo started volume production of the new polyimide laminate “Upicel H”with thick copper foil for flex circuits used in autos.

5. Idemitsu founded a new subsidiary in Switzerland for R&D work of organic EL materials cooperating with BASF.

6. Hitachi Solutions rolled out a voice recognition and management system for telephone monitoring in finance companies.

7. Omron opened an automation center in Seoul, Korea, for customer service related to factory automation devices.

8. Sharp opened an R&D center in Shintzen China for white goods and home appliances. It will cover southeastern Asia.

9. Panasonic commercialized a new lighting system LINK STYLE LED. It manages the lighting in the rooms by Bluetooth.

10. Air Water started field testing of Shikaoi Hydrogen Firm. Hydrogen gas is generated from biomass materials and supplied to the area.

11. AIST developed a simple process to generate pure nano carbon thin layers on various substrates including glass and rubber using appropriate lighting.

12. Nippon Paper developed a hybrid material of pulp cellulose and inorganic compounds named Mineral Hybrid Fiber.

13. Hitachi High Technologies codeveloped equipment to generate thin layers with Plasma-Enhanced Atomic Layer Deposition with Kustaa Poutiainen in Finland.

14. Panasonic will found a new subsidiary, Panasonic Eco Solutions Solar New York America, for manufacturing and marketing photovoltaic modules.

15. Konica-Minolta agreed to a joint venture with Pioneer to create organic EL lighting, especially in automobiles.

16. Toyota Motors started to operate new forklifts powered by fuel cells in Motomachi Plant in Aichi Prefecture.

Recent Articles of DKN Research

Find the full articles here.